Thermoplastic elastomer, manufacturing method of thermoplastic elastomer and yoga wheel

A thermoplastic elastomer, yoga technology, applied in gymnastics equipment, sports accessories, stilts, etc., can solve the problems of difficult recovery, difficult to control for beginners, weak elasticity of thermoplastic elastomer, etc., to achieve good elasticity, stable flexibility, deformation recovery ability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Thermoplastic elastomer, consisting of the following components in parts by weight:

[0022]

[0023] The method for preparing the above-mentioned thermoplastic elastomer comprises fully mixing the above-mentioned components in a high-speed thermal mixer, injecting the mixture into a twin-screw extruder for plasticization and cross-linking, extruding and forming, and then fully cooling through a water circulation cooling tower .

Embodiment 2

[0024] Example 2: Thermoplastic elastomer, consisting of the following components in parts by weight:

[0025]

[0026] The method for preparing the above-mentioned thermoplastic elastomer comprises fully mixing the above-mentioned components in a high-speed thermal mixer, injecting the mixture into a twin-screw extruder for plasticization and cross-linking, extruding and forming, and then fully cooling through a water circulation cooling tower .

Embodiment 3

[0027] Embodiment 3: thermoplastic elastomer, consists of the following components by weight:

[0028]

[0029] The method for preparing the above-mentioned thermoplastic elastomer comprises fully mixing the above-mentioned components in a high-speed thermal mixer, injecting the mixture into a twin-screw extruder for plasticization and cross-linking, extruding and forming, and then fully cooling through a water circulation cooling tower .

[0030] The thermoplastic elastomer produced by the invention has good elasticity and strong deformation recovery ability.

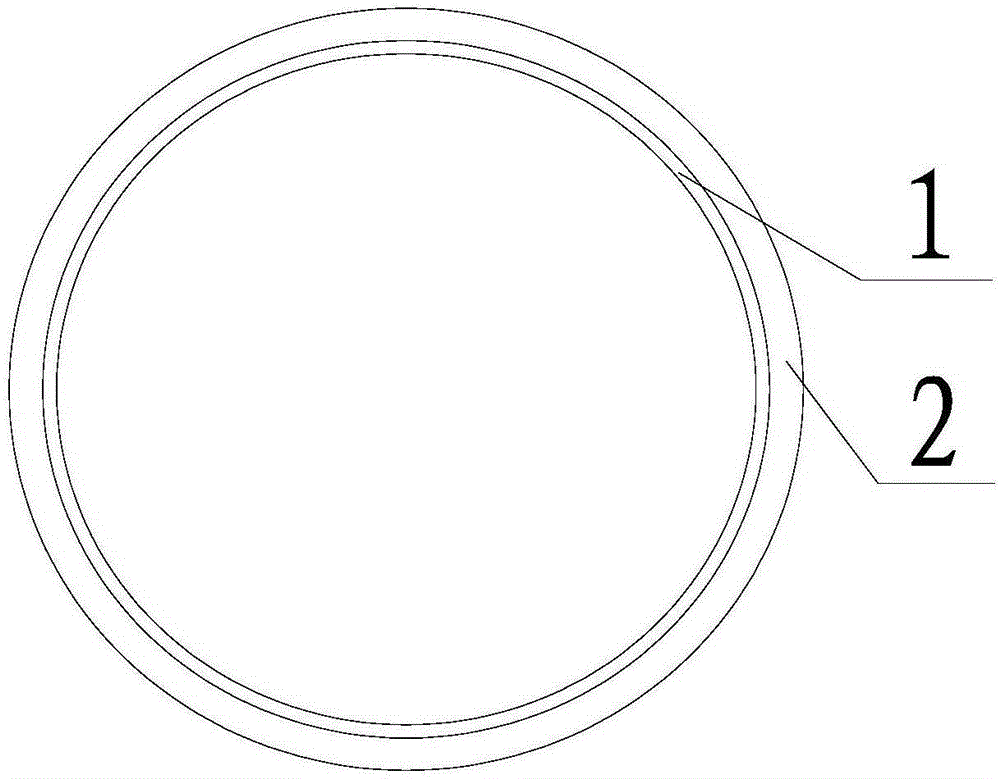

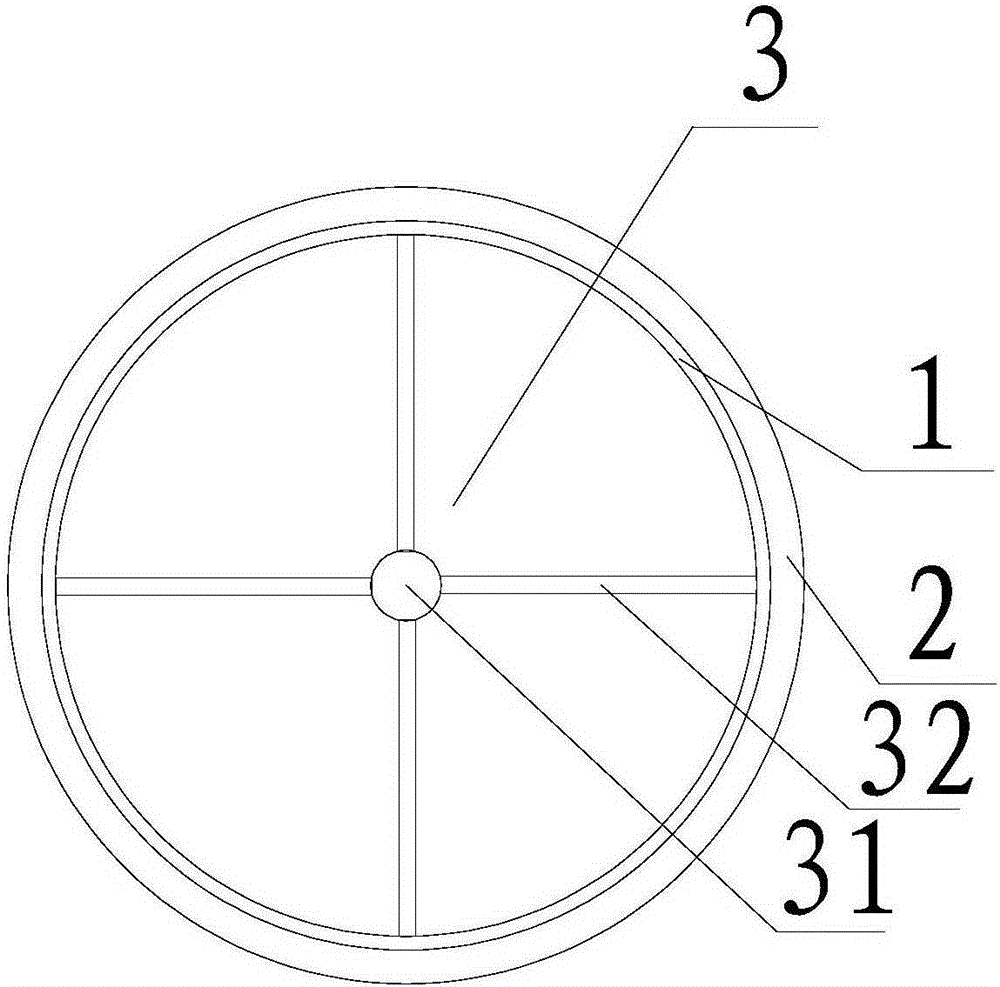

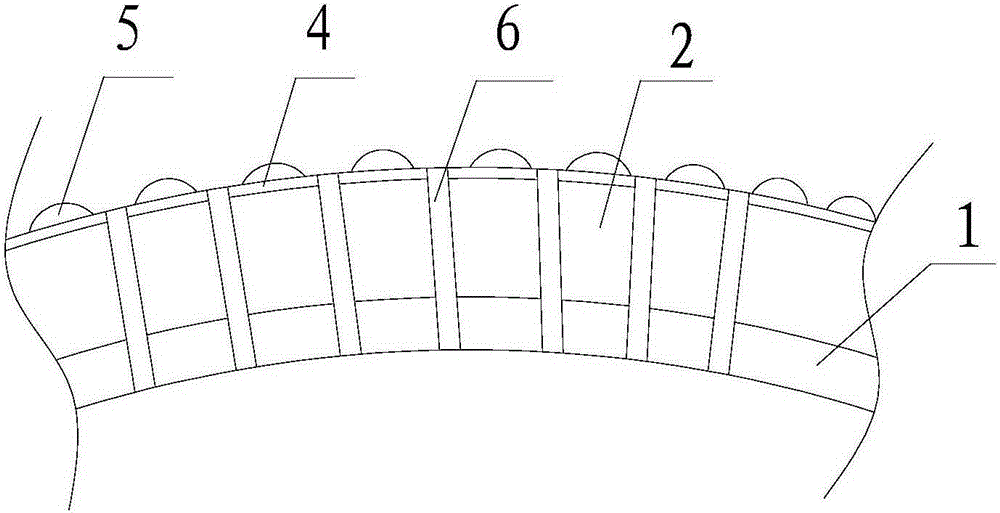

[0031] like figure 1 As shown, the yoga wheel includes a wheel body 1, and the wheel body 1 is provided with a pad body 2 in a circumferential direction. The pad body 2 is injection-molded with the thermoplastic elastomer made above, and the wheel body 1 can be injection-molded with polycarbonate or ABS plastic. The pad body 2 can be connected with the wheel body 1 by sleeve or gluing. The edges of the two sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com