Self-suction airlift fermenting tank

An air-lift fermentation tank, self-priming technology, applied in the field of fermentation tanks, can solve the problems of unsatisfactory gas-liquid mixing effect, inability to rotate, and inability to apply high-viscosity material fermentation, etc., to achieve good gas-liquid mixing effect and simple structure , Good effect of gas-liquid mixing and dispersing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

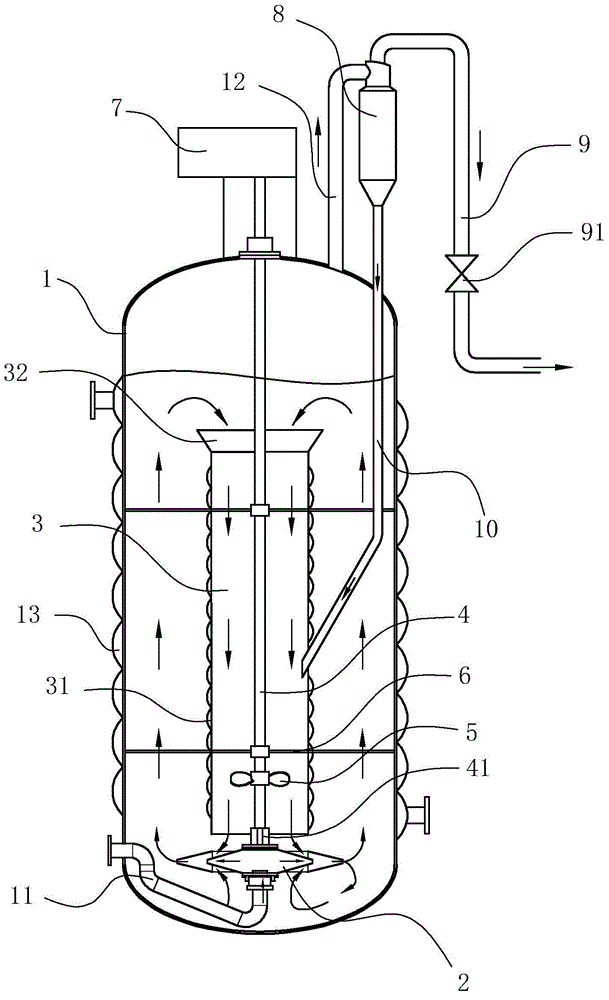

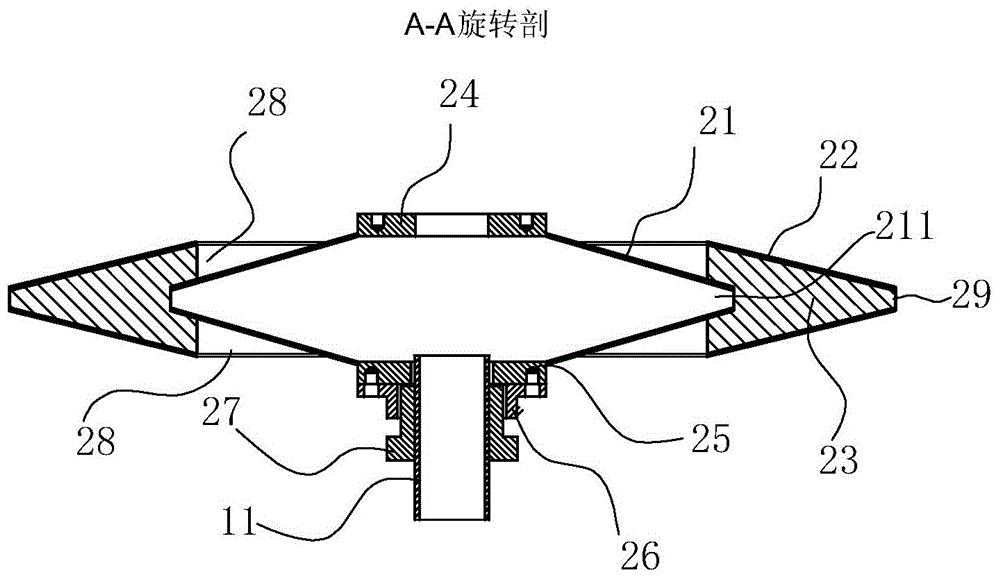

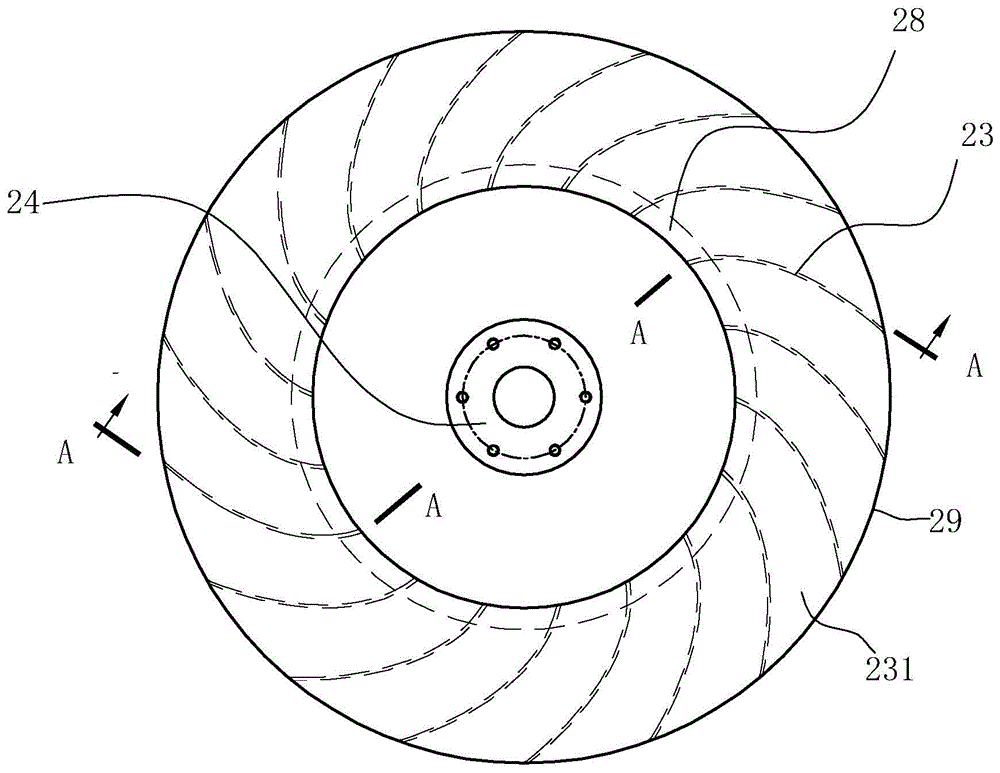

[0019] Such as Figure 1~3 As shown, the self-priming air-lift fermenter of the present embodiment includes a cylindrical tank body 1, an air intake device, an exhaust device, a flow guiding device, a cooling device, a stirring device and an air intake pipe arranged on the tank body 1 11. Exhaust pipe 12, the air intake pipe 11 is located at the bottom of the tank body 1 and connected with the air intake device, and the exhaust pipe 12 is located at the top of the tank body 1 and connected with the exhaust device.

[0020] The air intake device is not a simple annular pipe with densely distributed small holes, nor a jet gas-liquid mixer, but a rotatable swirl mixer 2, which is located at the bottom of the tank body 1. The stirring device includes a stirring shaft 4 and a stirrer 5, the stirring shaft 4 is arranged on the axis of the tank body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com