Efficient internal and external wall small-size face brick pasting mold

A technology for interior and exterior walls and bricks, which is applied to buildings and building structures, etc., can solve the problems of difficulty in controlling the fullness of mortar, unsuitable control of surface flatness and verticality, and low construction efficiency, so as to improve construction quality and reasonable structural design. Reliable and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

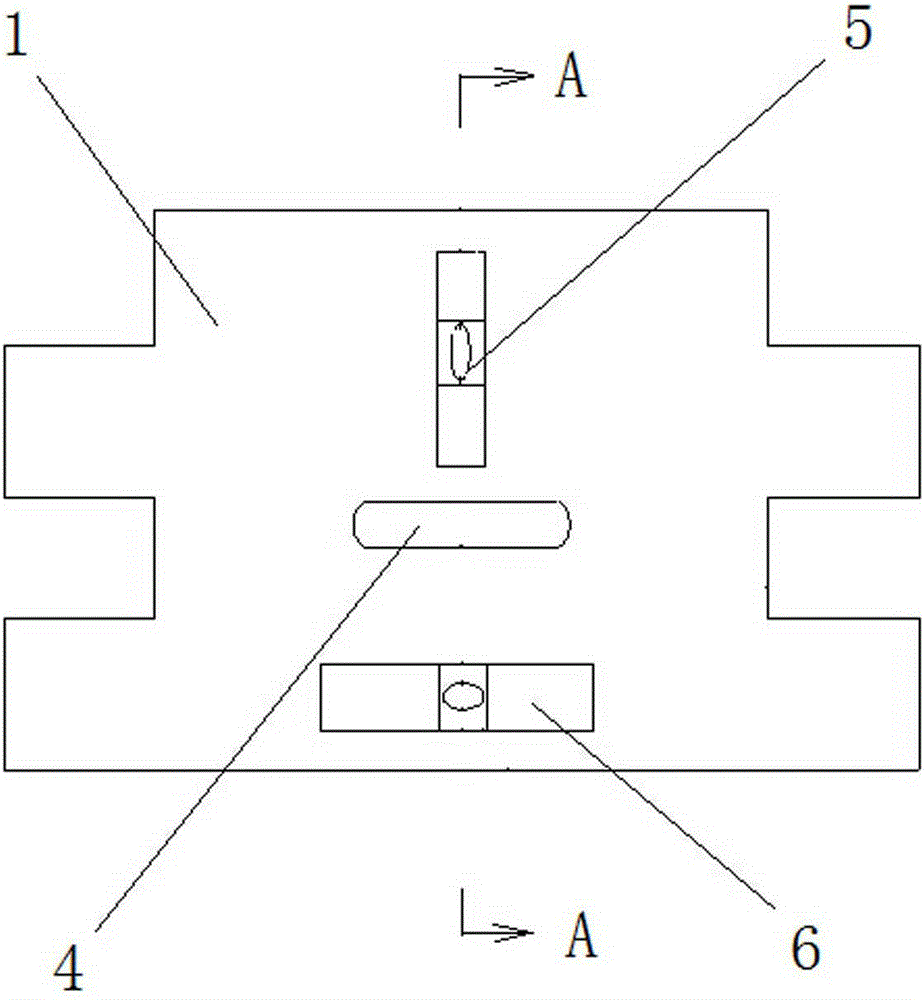

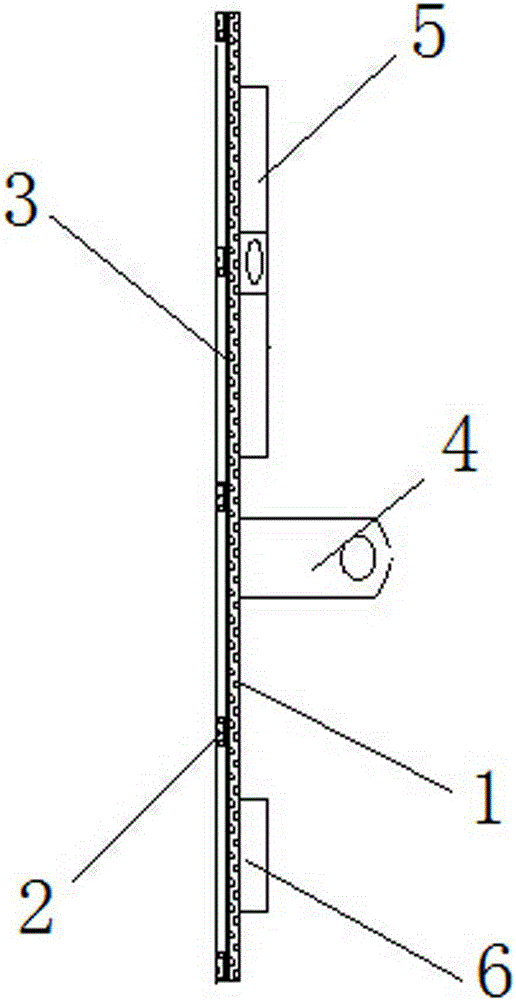

[0010] The high-efficiency small-sized face brick paste mold for interior and exterior walls includes a bottom plate 1. The front face of the bottom plate 1 is provided with a face brick groove 3 surrounded by a number of horizontally and vertically intersecting convex ribs 2. A handle 4 is provided in the middle of the rear end of the bottom plate 1. A verticality detection level 5 placed vertically and a flatness detection level 6 placed horizontally are provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com