Indoor sectional insulating ladder for transformer substation

A technology for substations and insulating ladders, applied in ladders, buildings, building structures, etc., can solve the problems that the insulating ladder cannot be placed in the working area of the through-wall casing, increase the power outage time, and be inconvenient to use, saving manpower and reducing Power loss, stable and firm support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

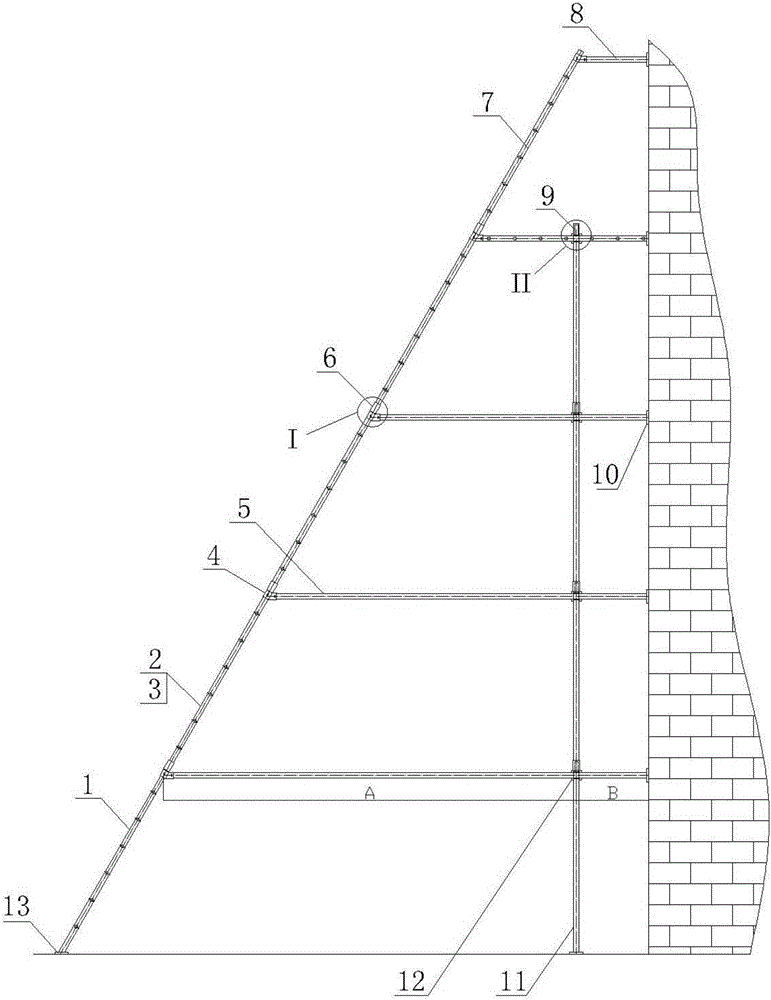

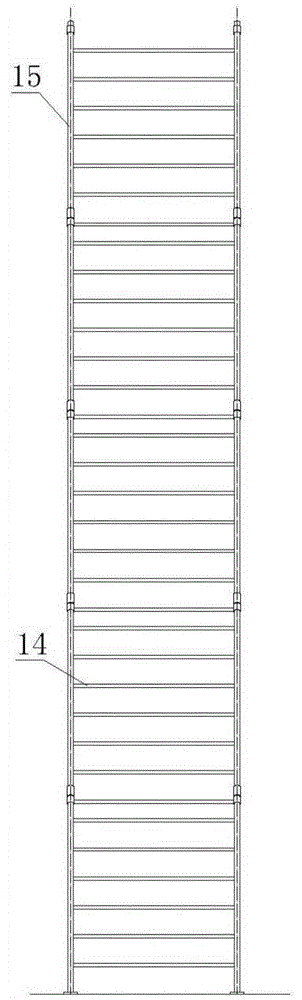

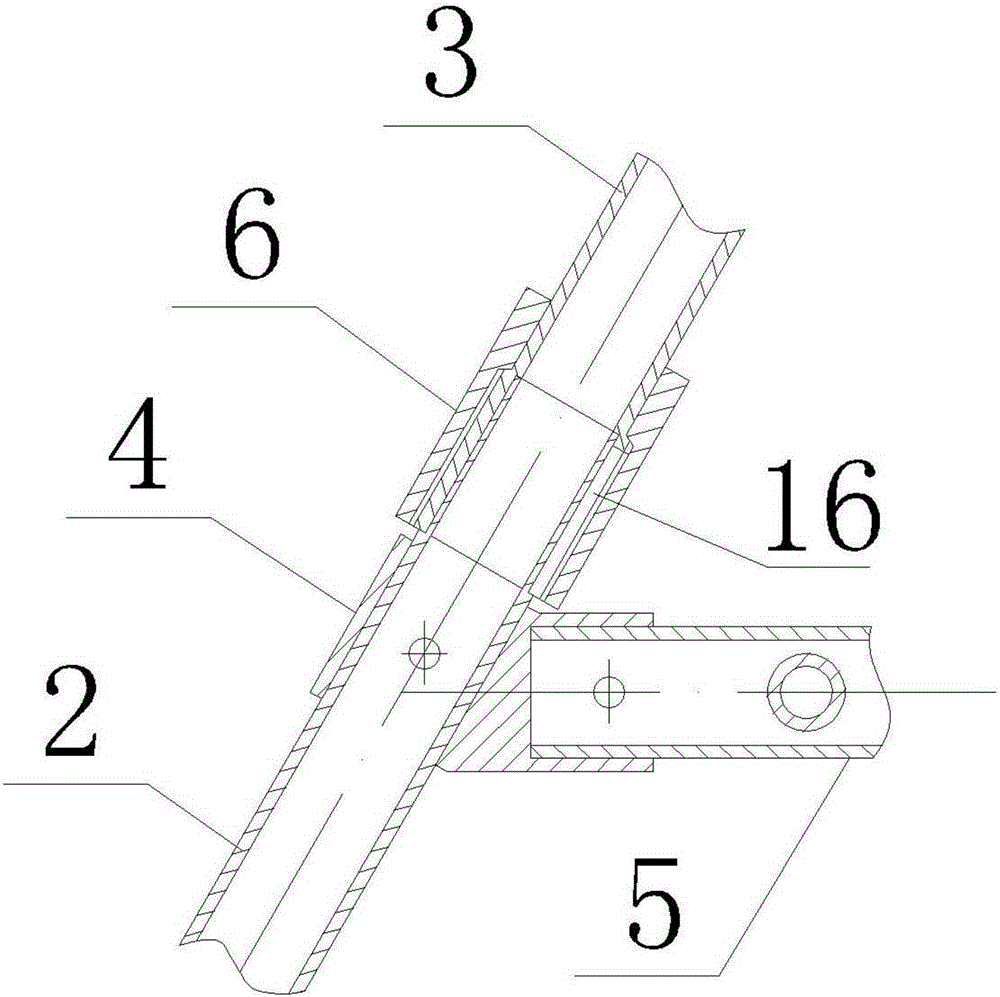

[0023] Such as Figure 1-Figure 2 As shown, the present invention relates to a substation indoor segmented insulation ladder, which is formed by sequentially connecting a multi-section combined lower ladder 1 and a single combined upper ladder 7 made of insulating materials to form a right-angled trapezoid. The combined ladder 1 includes an inclined ladder 2 arranged obliquely and a flat ladder 5 arranged horizontally. The inclined ladder 2 and the flat ladder 5 are respectively composed of two main pipes 3 and a plurality of pipes evenly distributed between the two main pipes 3. The cross bar 14 is formed, wherein the upper ends of the two main pipes 3 of the inclined ladder 2 and the outer ends of the two main pipes 3 of the flat ladder 5 are detachably connected by insulating clips 4, and the two main pipes 3 of the flat ladder 5 are kept away from the inclined ladder 2 by one Two branch pipes 11 are connected laterally symmetrically, and the upper ends of the two branch pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com