Mitigative transition non-linear rigid traction joint and non-linear rigidity control method thereof

A nonlinear and rigid technology, applied in springs, springs/shock absorbers, mechanical equipment, etc. made of plastic materials, can solve the problem of insufficient nonlinear stiffness to ease transition characteristics, and achieve the effect of optimal riding comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

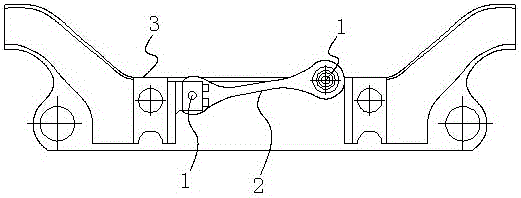

[0033] Embodiment 1: as Figure 3 to Figure 7As shown, a traction node with moderate transitional nonlinear stiffness includes a metal mandrel, a metal sheath 5 and a rubber elastic body 6, the metal mandrel includes a shaft body 41 and a flange 42 arranged in the middle of the shaft body 41, The rubber elastic body 6 is arranged between the metal mandrel flange 42 and the metal jacket 5, and the traction node forms a real direction X and a space direction Y along its radial direction (the space direction Y is the working direction), and The real direction X and the empty direction Y are perpendicular to each other; along the real direction X, the metal mandrel flange 42, the rubber elastic body 6 and the metal jacket 5 are bonded to form a real structure, and along the empty direction Y, the rubber elastic body 6 is provided with a space 61 symmetrical to the axis of the metal mandrel 7, and the metal mandrel flange 42 is a prism whose bottom surface 45 is a parallelogram, an...

Embodiment 2

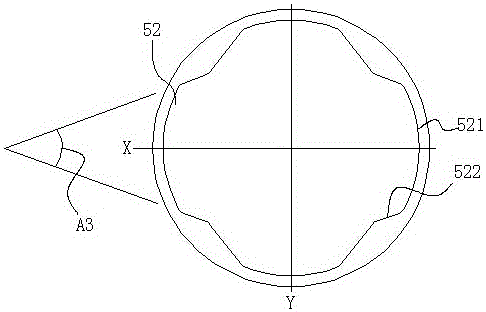

[0043] Embodiment 2: as Figure 9 and Figure 10 As shown, compared with Example 1, the difference is that: along the real direction X, on the inner wall of the metal jacket 5, a real direction groove 52 symmetrical to the axis of the metal mandrel is provided, and the rubber elastic body The outer surface and the inner surface of 6 match with the inner wall surface of the metal jacket 5 and the outer surface of the metal mandrel flange 42 respectively.

[0044] When the traction joint is vulcanized and formed, the metal mandrel, the metal jacket and the elastic rubber body are formed into a whole through vulcanization, and the vulcanized body is subjected to radial extrusion and then secondary finishing to form a finished product. After the radial extrusion, since the rubber of the elastic rubber body along the empty direction Y is less than that along the real direction X and has gaps, the reaction force of the rubber elastic body due to radial extrusion is in the air direc...

Embodiment 3

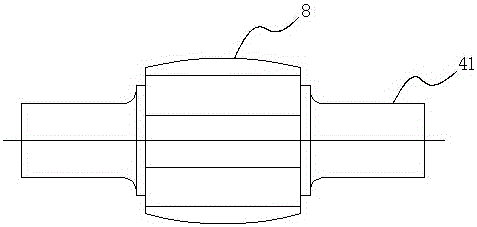

[0047] Embodiment 3: as Figure 11 to Figure 13 As shown, compared with Example 1, the difference is that a pair of opposite rounded corners of the parallelogram prism in the air direction Y are provided with a radian 8 in the axial direction of the metal core axis, and the opposite The arc of the rounded corners is symmetrical about the axis of the metal mandrel, that is, a pair of opposite rounded corners of the flange of the metal mandrel in the air direction Y are arc-shaped in the axial direction of the metal mandrel, and the opposite arc-shaped circles The angular parts are symmetrical about the axis of the metal mandrel.

[0048] In order to reduce the deflection stiffness when the traction node is working, in this embodiment, a pair of opposite rounded corners of the parallelogram prism in the space direction X are designed as rounded corners 9 with radians along the axial direction of the metal mandrel. This radian makes the free surface of the rubber body greatly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com