Dual-cold source four-pipe-system air conditioner system

An air-conditioning system, four-control technology, applied in the direction of air-conditioning system, heating and ventilation control system, heating and ventilation safety system, etc., can solve the problem of dehumidification capacity reduction of air-conditioning system, achieve the effect of reducing energy consumption and increasing load ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

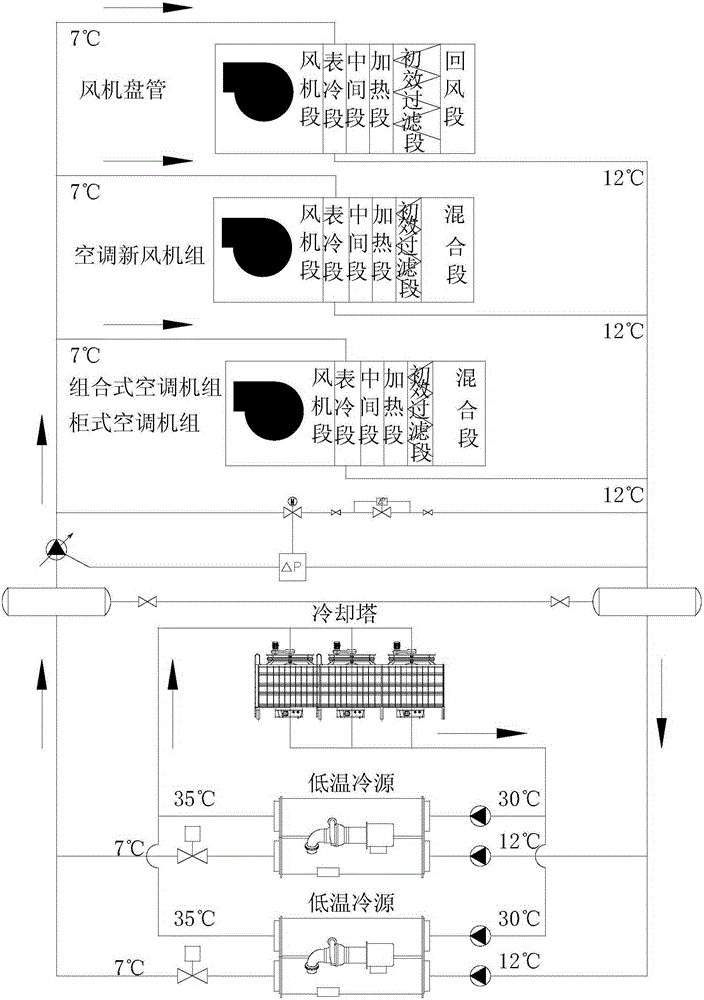

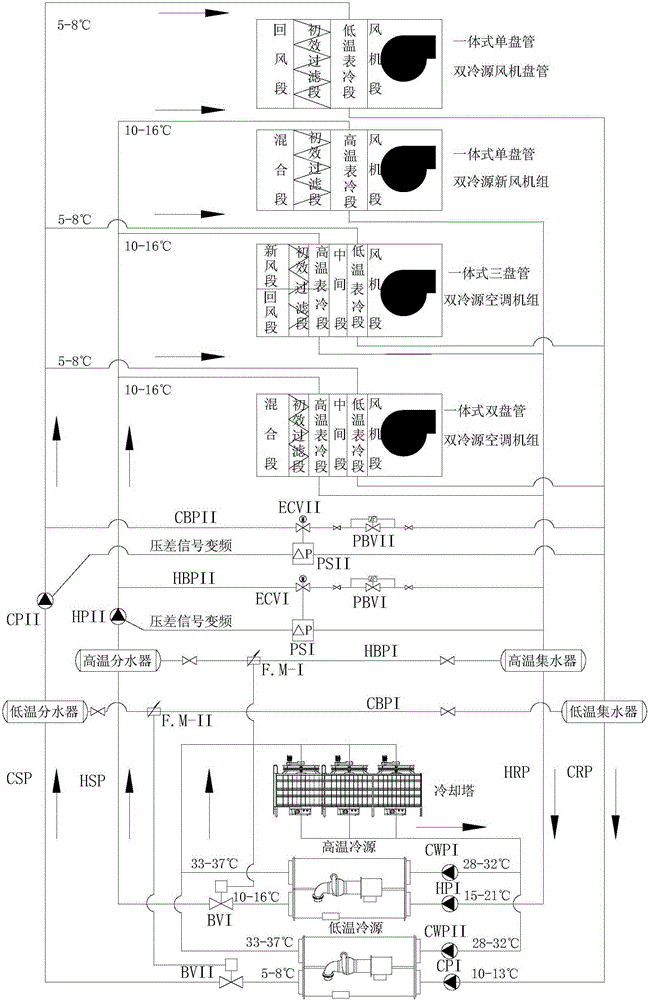

[0052] Example 1: Dual cold sources in parallel with four pipes and two-stage pump air-conditioning water system

[0053] Such as image 3 As shown, the air-conditioning cold source of the air-conditioning water system with two parallel cooling sources and four-pipe secondary pumps is composed of a high-temperature cooling source and a low-temperature cooling source, and the high-temperature cooling source and the low-temperature cooling source are connected in parallel; the high-temperature cooling source and the low-temperature cooling The sources are all cooled by cooling towers; the cooling water at the outlet of the cooling towers passes through the first cooling water pump CWPI and the second cooling water pump CWPII to provide cooling capacity for the high temperature cold source and the low temperature cold source respectively.

[0054] The supply water temperature of the high-temperature cold source is 10-16°C, the return water temperature is 15-21°C, and the temperat...

Embodiment 2

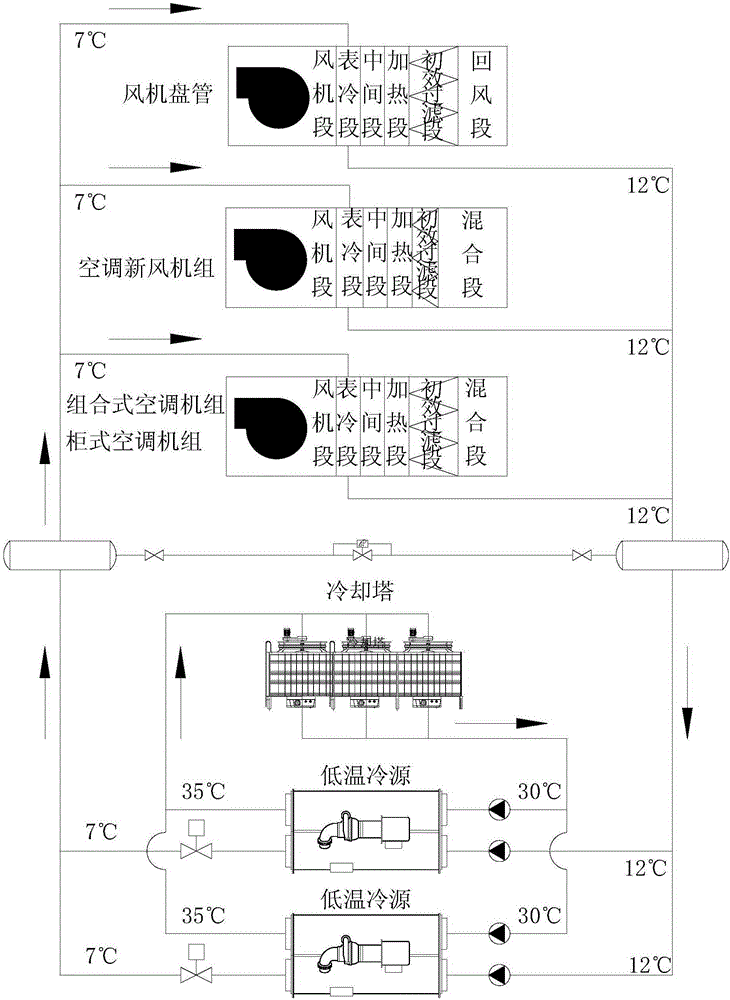

[0061] Example 2: Parallel connection of dual cold sources and four-pipeline primary pump air-conditioning water system

[0062] Such as Figure 4 As shown, different from Embodiment 1, in this system, only the primary pump is used as the fluid driving source. The high-temperature chilled water secondary pump unit HPII and the low-temperature chilled water secondary pump unit CPII are cancelled. The high-temperature chilled water first-stage pump unit HPI and the low-temperature chilled water first-stage pump unit CPI can use fixed-frequency pumps or variable-frequency pumps at the same time.

[0063] In this embodiment, the HPI of the high-temperature chilled water first-stage pump unit and the CPI of the low-temperature chilled water first-stage pump unit are frequency conversion ( Figure 4 is the structural schematic diagram of this embodiment), the second high-temperature bypass pipe HBPII between the high-temperature water supply pipe HSP and the high-temperature retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com