A comprehensive monitoring and evaluation method for the safety of in-service metal pipelines and pressure-bearing parts

A technology of metal pipes and evaluation methods, applied in the direction of measuring devices, instruments, etc., can solve the problems of single detection/monitoring method, low detection efficiency, wear and tear, etc., and achieve the effect of improving safety evaluation efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

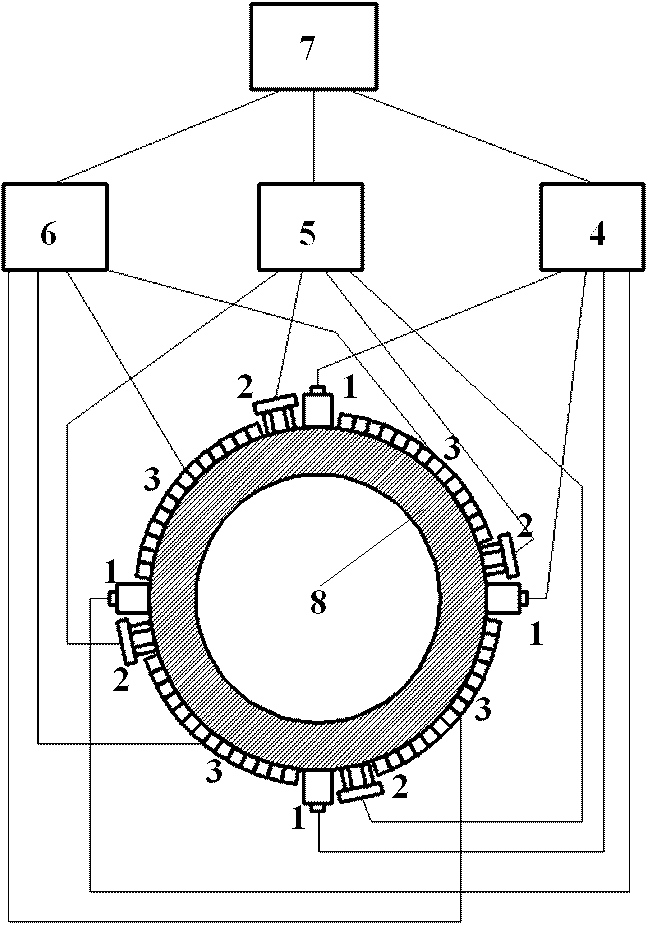

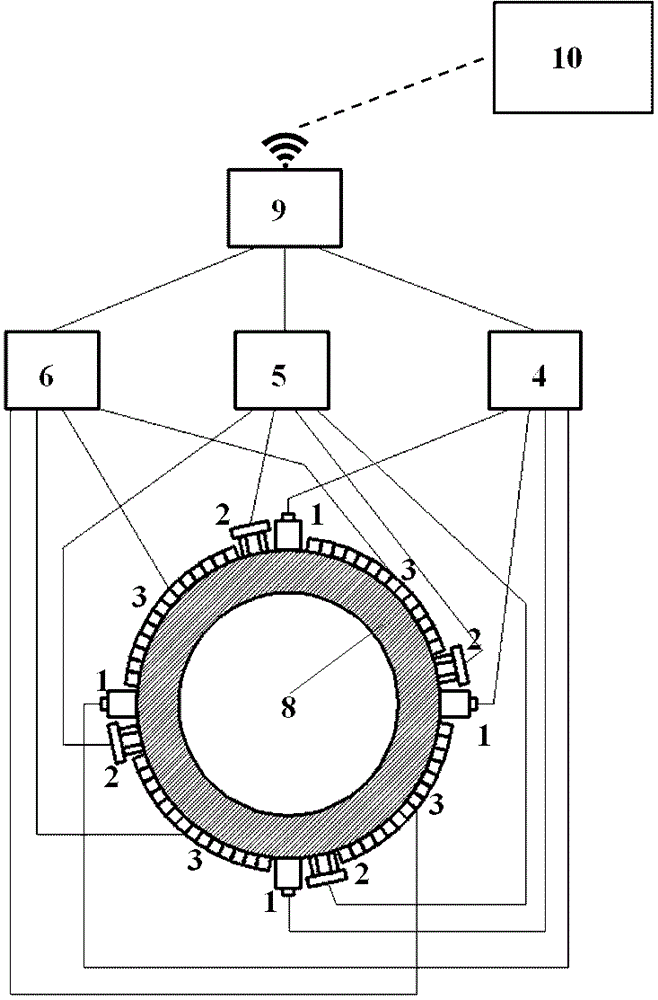

[0021] figure 1 The first embodiment shown is a comprehensive monitoring and evaluation method for the safety of in-service metal pipelines and pressure parts, which uses an integrated detection method that combines ultrasonic thickness measurement, electrochemical corrosion detection, and metal magnetograph detection to improve The safety monitoring accuracy of in-service metal pipelines 8 is realized to realize the comprehensive evaluation of the safety status of in-service metal pipelines and pressure-bearing parts, including the following steps,

[0022] a. An ultrasonic thickness measuring probe 1, an electrochemical corrosion detection probe 2, and a metal magnetic memory array detection probe 3 are arranged on the monitoring part of the metal pipeline 8 under inspection; the metal magnetic memory array detection probe 3 includes a plurality of detection array elements; Ultrasonic thickness probe 1 is connected to ultrasonic thickness gauge 4; electrochemical corrosion d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com