Automatic assembly device of magnetic tile/clamping spring

A technology of automatic assembly device and drive device, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of automatic assembly circlip, magnetic tile workpiece transmission mechanism, etc., to improve assembly quality and efficiency, simplify structural composition, guarantee The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific examples.

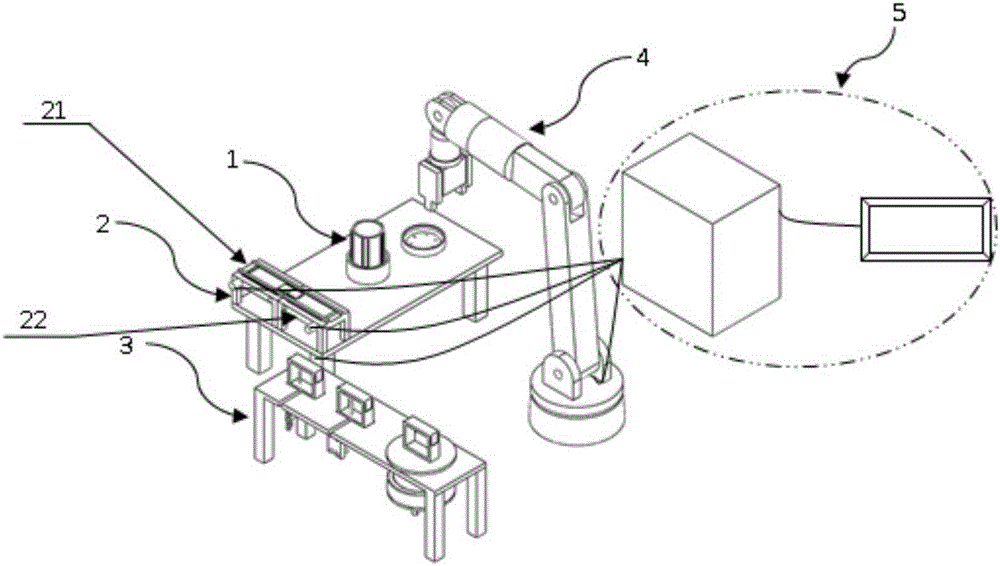

[0044] Such as figure 1 As shown in the figure, an automatic assembly device for a magnetic tile retainer, including a mounting table 1 for assembling magnetic tiles and V-shaped retaining springs, a feeding mechanism 2 mounted on the mounting table 1, and a jig arranged at one end of the mounting table 1 The magazine 3, the delivery arm 4 arranged near the mounting table 1 and the jig magazine 3, and the control unit 5 for controlling the device. The control unit 5 includes a control cabinet 51 and a hand-held controller 52 for controlling the conveying arm 4 and the feeding mechanism 2 .

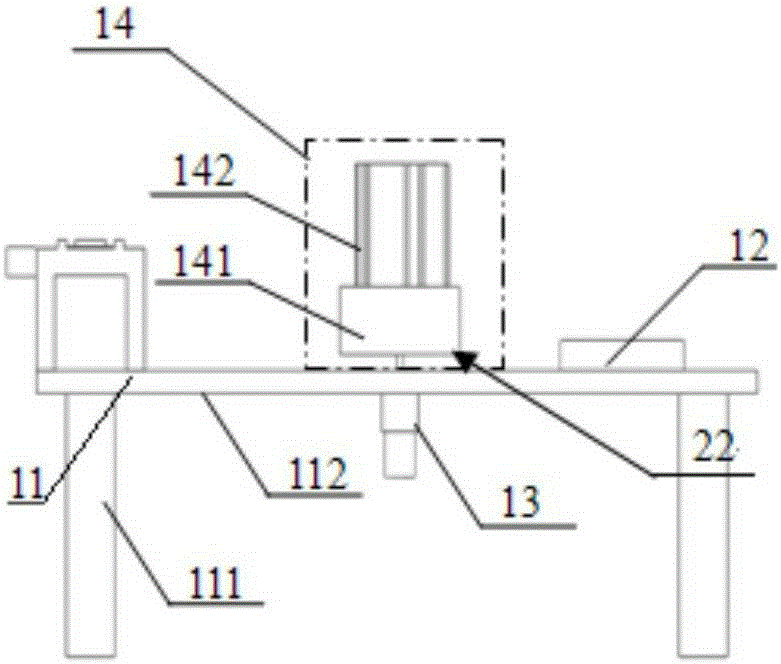

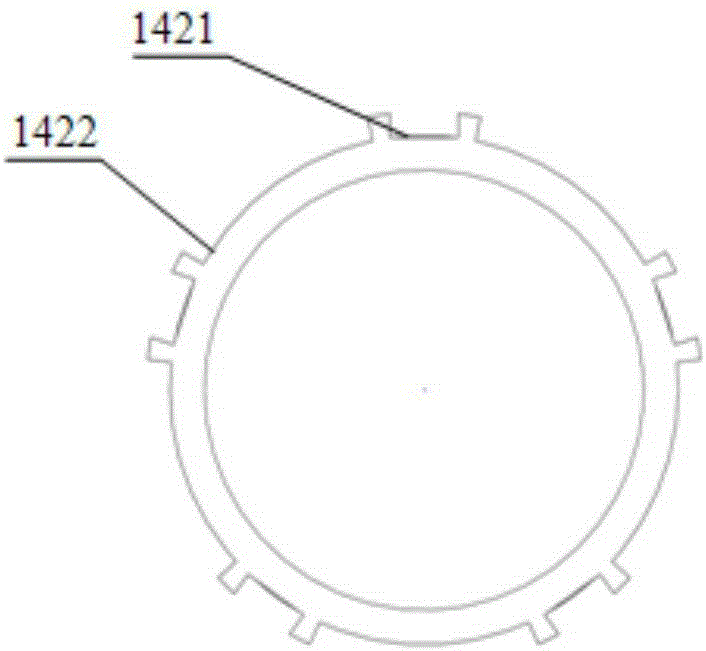

[0045] The mounting table 1 is used for inserting magnetic tiles and V-shaped retaining springs. see figure 2 and image 3, The installation platform 1 includes a support platform 11 , a chassis tray 12 , a driving device 13 and a positioning fixture 14 . Wherein, the supporting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com