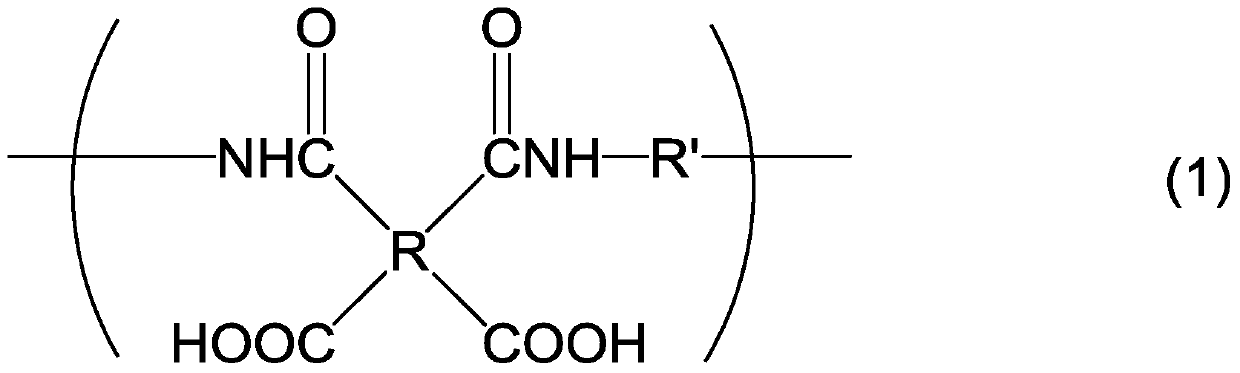

Polyimide Precursor Solution

A technology of polyimide precursor and polyamic acid, applied in the direction of coating, etc., can solve the problem of difficulty in obtaining polyimide precursor with high degree of polymerization, and achieves easy process control, excellent environmental suitability, and flowability. Good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

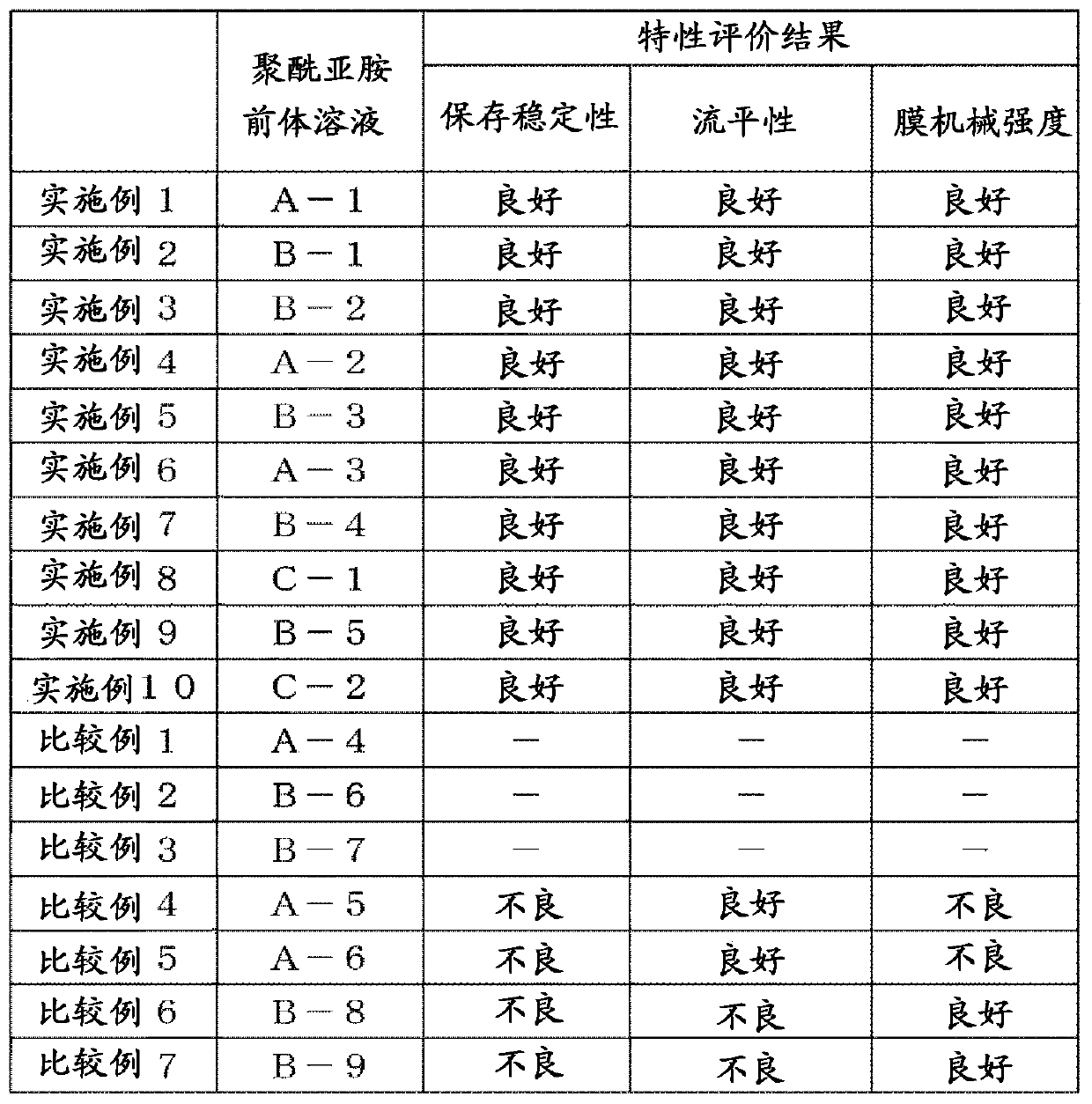

[0064] Dissolve the mixture of polyamic acid powder A and 1,2-dimethylimidazole (pKa 7.7) (use 2.5 moles of 1,2-dimethylimidazole relative to 1 mole of structural units of polyamic acid) at 25°C In ethylene glycol, as a polyimide precursor, polyimide precursor solution A-1 having a concentration of 15% by mass was obtained. Table 1 shows the evaluation results of the properties of the precursor solution.

Embodiment 2

[0066] Dissolve the mixture of polyamic acid powder B and 1,2-dimethylimidazole (pKa 7.7) (use 2.5 moles of 1,2-dimethylimidazole relative to 1 mole of structural units of polyamic acid) at 25°C In ethylene glycol, as a polyimide precursor, polyimide precursor solution B-1 having a concentration of 15% by mass was obtained. Table 1 shows the evaluation results of the properties of the precursor solution.

Embodiment 3

[0068] Except having used 2-ethyl-4-methylimidazole (pKa 8.3) as a basic compound, it carried out similarly to Example 2, and obtained polyimide precursor solution B-2. Table 1 shows the evaluation results of the properties of the precursor solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com