Euglena spp. microalgae, polysaccharide manufacturing method, and organic compound manufacturing method

A manufacturing method and technology of polysaccharides, applied in the direction of microorganism-based methods, microorganisms, microorganisms, etc., can solve the problem that the performance of organic compounds such as polysaccharides is not necessarily sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0208] 200 mL of the compositions shown in Table 2 were placed in a 500 mL Sakaguchi flask. Furthermore, glucose and yeast extract were added so that the concentration of glucose may be 15 g / L, and the concentration of yeast extract may be 5 g / L. Further, the pH was adjusted to 4.0 by adding hydrochloric acid to prepare a culture solution.

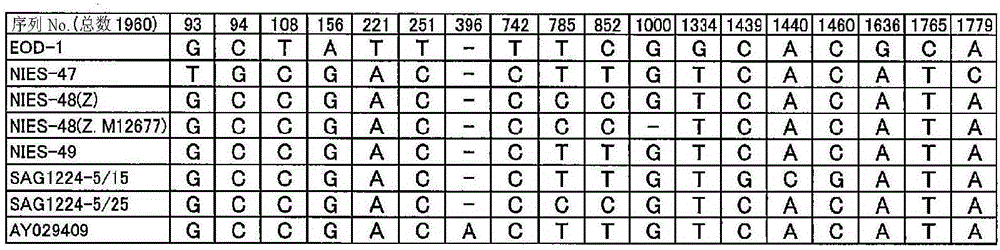

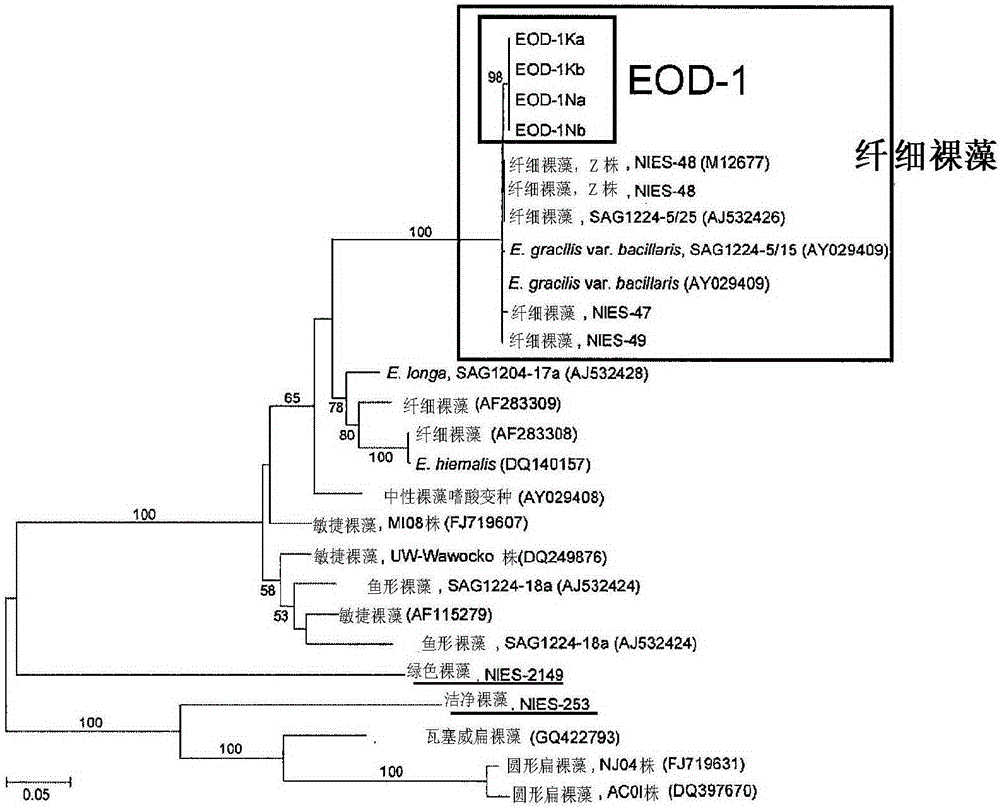

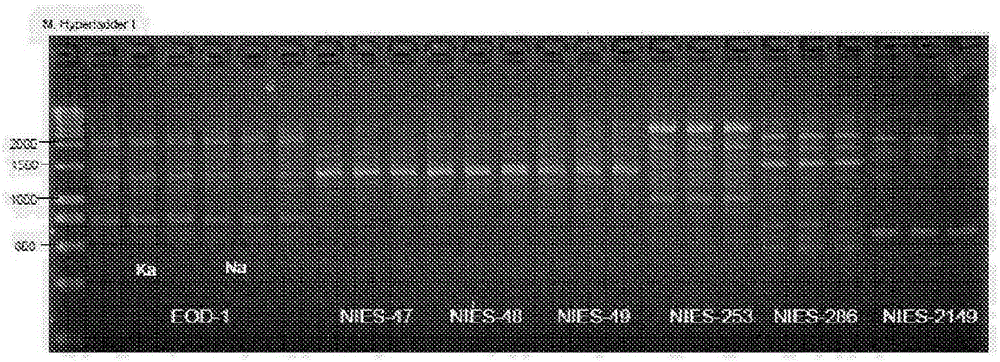

[0209] Then, microalgae of the genus Euglena ( Euglena gracilis ) EOD-1 strain was cultured for 3 days, and the cultivation step was carried out.

Embodiment 2-4

[0211] The culture procedure was carried out in the same manner as in Example 1, except that the amount of glucose was changed so that the glucose concentrations in the culture solution were 20 g / L, 25 g / L, and 30 g / L.

Embodiment 5

[0222] Except for the point of using a 300 ml Erlenmeyer flask; use of a culture solution in which beer was added so that the concentration of ethanol derived from beer became 2.5% by volume relative to the composition shown in 50 mL of Table 2; yeast extract was not added to the culture solution This point; repeating 12 hours of light irradiation environment and 12 hours of dark environment to cultivate this point; the cultivation time is 7 days other than this point, by cultivating microalgae of the genus Euglena ( Euglena gracilis ) EOD-1 strain, the culturing step was carried out. In addition, photosynthetic photon flux density (PPFD) is about 100 μmol / m 2 ·s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com