Active thermal management and thermal runaway prevention for high energy density lithium ion battery packs

A battery thermal management, battery cell technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as increased weight and volume, increased total cost, and thermal runaway of battery cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

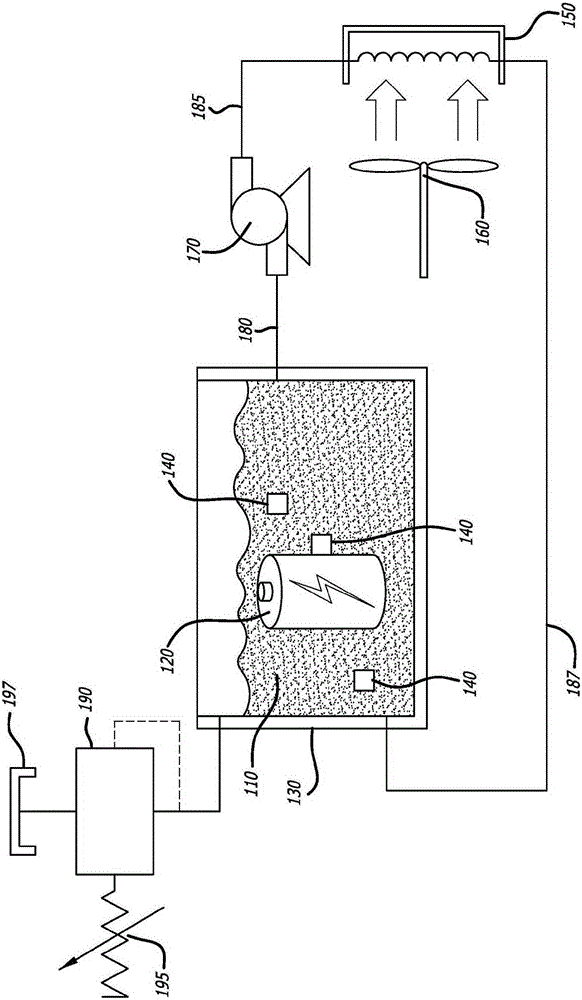

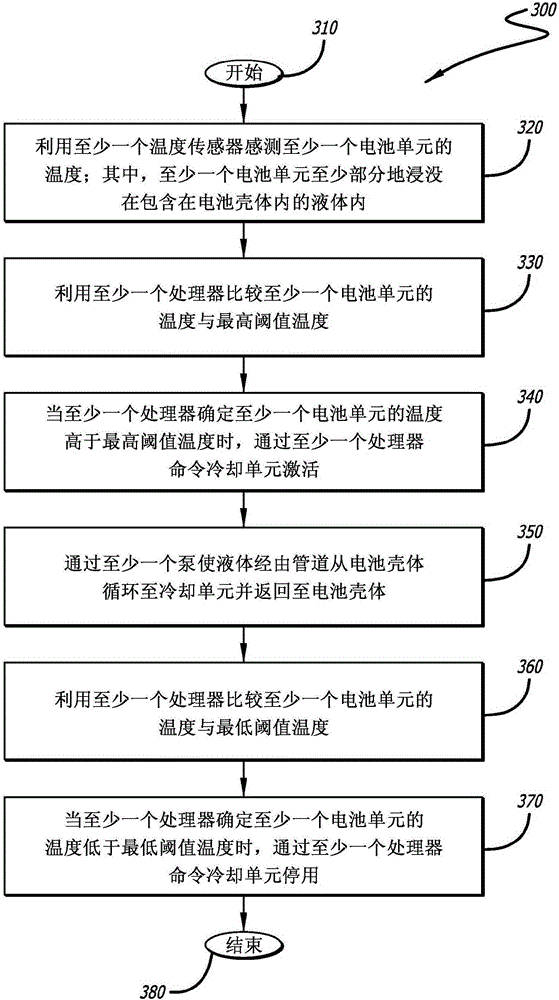

[0023] The methods and devices disclosed herein provide an operational system for active thermal management and thermal runaway prevention of high energy density lithium-ion battery packs. Specifically, the system provides improved thermal performance for battery thermal runaway prevention and active fluid immersion cooling for lithium-ion (or other chemical composition) battery cells and prevents or ends thermal runaway in damaged or abused battery cells. Ability to achieve improved safety and extended battery life with a small volume and light weight.

[0024] The system of the present disclosure solves two major concerns related to thermal battery management to ensure safety and long battery life. The two main concerns are: (1) maintaining a uniform temperature range between battery cells; and (2) controlling and isolating damaged or abused battery cells into thermal runaway conditions.

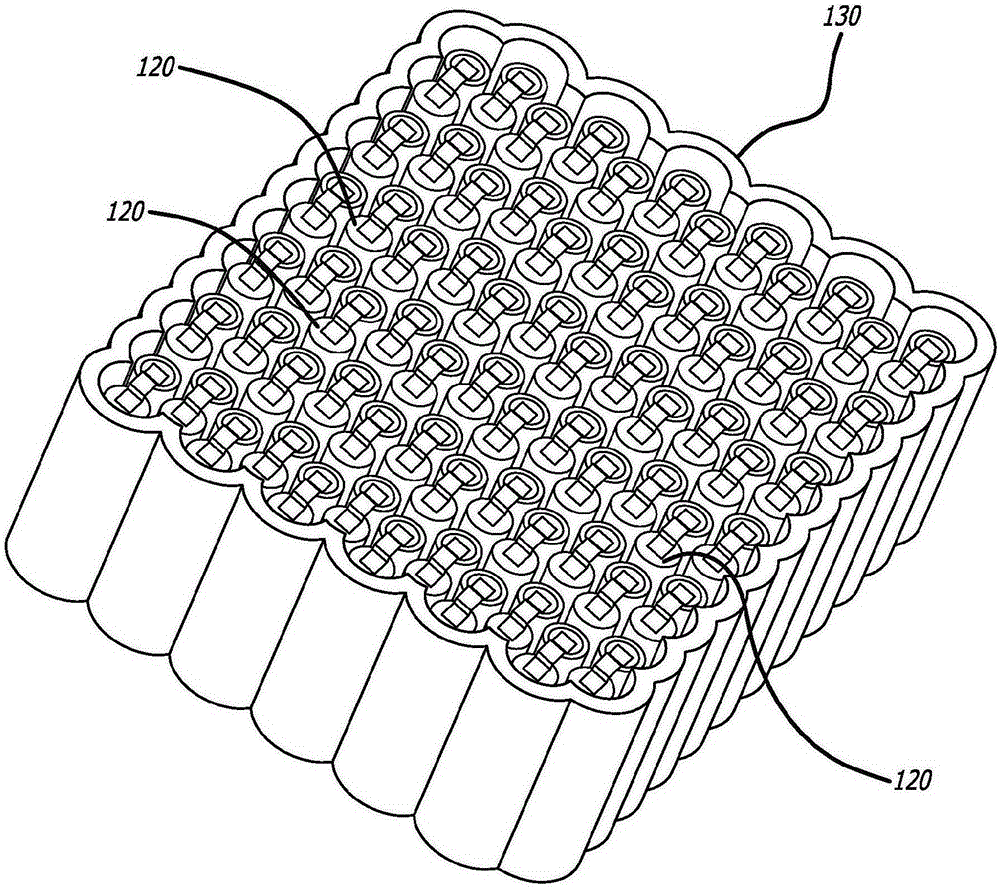

[0025] Specifically, the disclosed system uses direct fluid immersion that makes almost th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com