A conventional ditch opener for a no-tillage seeder

A seeder and ditch opener technology, which is applied in the direction of digging/covering ditches, application, planting methods, etc., can solve the problems of high seed leakage rate and laboriousness, and achieve the effects of saving seeds, saving labor, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

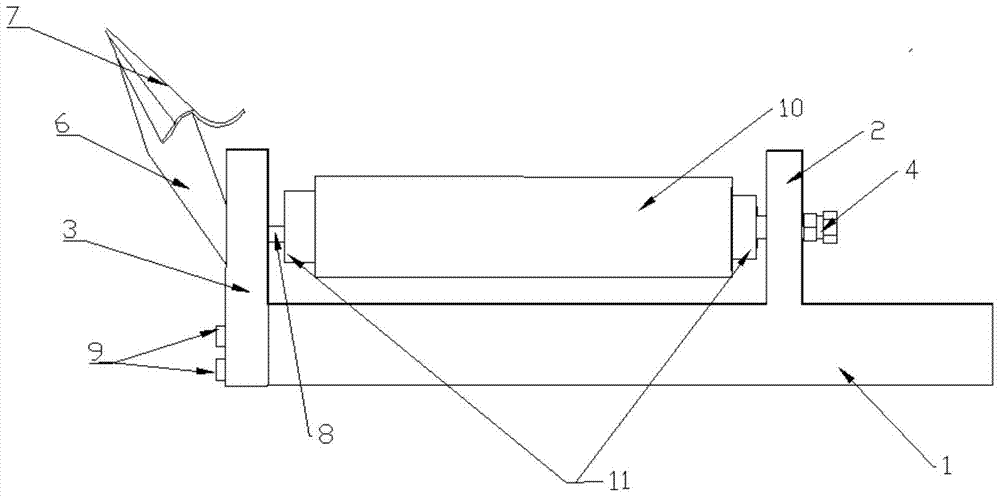

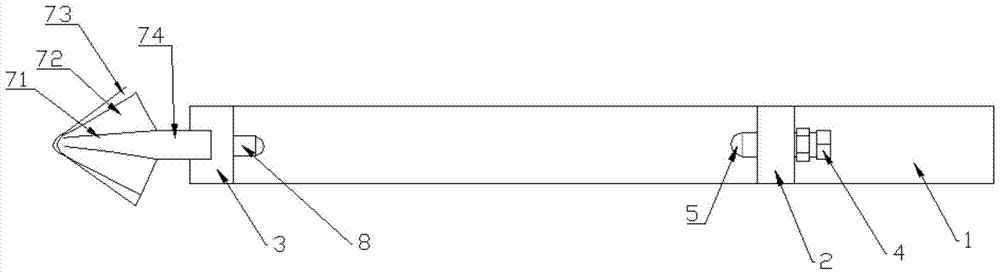

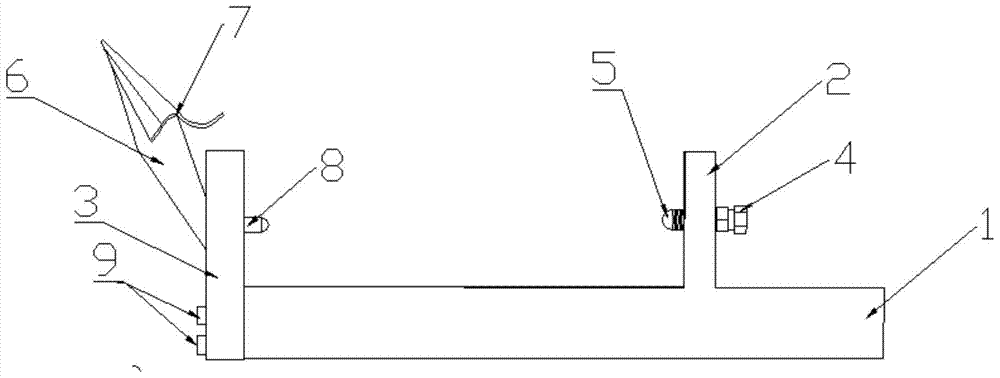

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention provides a common type ditch opener for a no-tillage planter, comprising a support 1, a share base 6, and a ditching share 7. A welding body 3 is fixed at the front end of the support 1, and the share base 6 is fixed on the On the front wall of the welded body 3, the ditching share 7 is fixed on the top of the sharer seat 6, which is characterized in that: a guide plate 2 is provided on the top surface of the other end of the support 1, and a guide plate 2 is arranged between the welded body 3 and the Between described guide plate 2, be provided with turning roller, described turning roller comprises turning roller, the bearing (not drawn) of turning roller two ends, the sealing plug 11 of turning roller two ends, described sealing plug 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com