Preparing experiment platform and method for modifying asphalt through rubber powder

A modified asphalt and experimental platform technology, applied in the field of rubber powder modified asphalt, can solve the problems of not being able to obtain the best production process online, waste quality of production materials, and large data deviation, so as to reduce the experimental reaction time and heating process , Improve the effect of rubber powder doping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

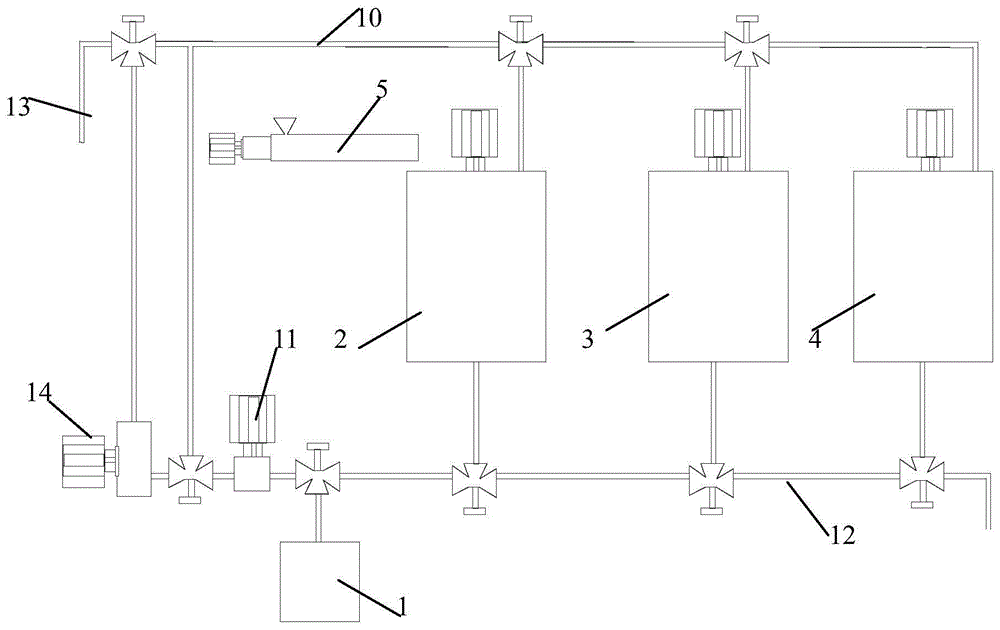

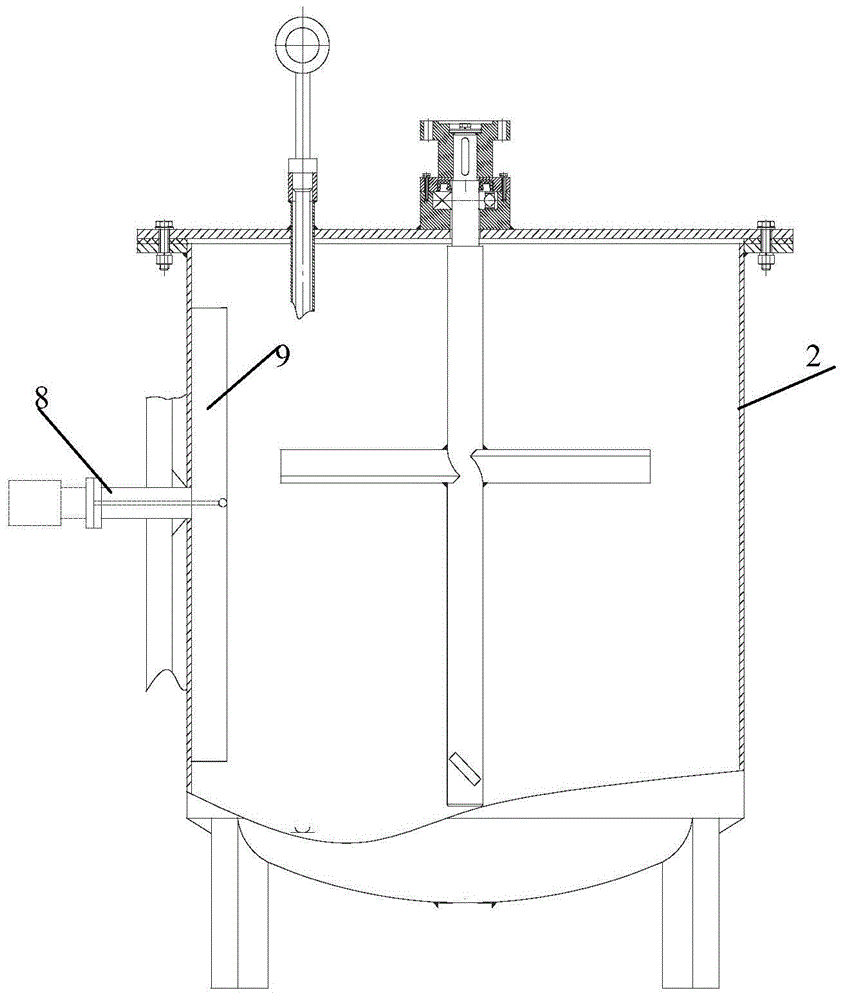

[0024] Such as Figure 1-2 As shown, the experimental platform for preparing rubber powder modified asphalt of the present invention includes a controller, an oil tank 1 for storing asphalt, a reactor 2, a heating tank 3 and a mother liquor tank 4, and a twisting tank for transporting rubber powder in the reactor. Dragon 5, the reaction kettle is provided with a temperature sensor, a viscosity sensor 8 and a weight sensor, the temperature riser and the mother liquor tank are respectively provided with a temperature sensor and a weight sensor, and the reaction kettle, the temperature riser and the mother liquor tank respectively include There is a tank body with a jacket, a stirring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com