Free radical induced graphite type nitrogen-doped graphene catalytic material and preparation method thereof

A catalytic material, graphite-type nitrogen technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of difficulty in adjusting the doping ratio of various forms of N, and achieve good electrocatalytic activity , expand the practical application prospects, and prepare the effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of a free radical-induced graphite-type nitrogen-doped graphene catalytic material, which specifically comprises the following steps:

[0038] (1) Weigh each raw material according to the proportion of raw material components: graphite powder 40~60wt%, sodium nitrate 0.50~0.80wt%, potassium permanganate 1.50~2.60wt%, concentrated sulfuric acid 4.00~6.00wt%, nitrite 5.00 ~10.00wt%, hydrogen peroxide 10.00~15.00wt%, the balance is water;

[0039] (2) After fully mixing and dissolving concentrated sulfuric acid, graphite powder, sodium nitrate and water in an ice bath at 0 to 5 °C, slowly adding potassium permanganate, and reacting at a constant temperature for 0.5 to 2 hours to obtain a mixed solution;

[0040] (3) placing the mixed solution obtained in step (2) in an oil bath at 90 to 100 ° C, and after constant temperature reaction for 0.5 to 1 h, hydrogen peroxide is added to remove the residual oxidant potassium permanganate;

[0041] (4) stirrin...

Embodiment 1

[0043] A free radical-induced graphite-type nitrogen-doped graphene catalytic material, the specific preparation method comprising the following steps:

[0044] (1) Weigh each raw material according to the proportion of raw material components: graphite powder 50wt%, sodium nitrate 0.65wt%, potassium permanganate 2.0wt%, concentrated sulfuric acid 5.0wt%, nitrite 8.0wt%, hydrogen peroxide 13.0wt%, The balance is water;

[0045] (2) After fully mixing and dissolving concentrated sulfuric acid, graphite powder, sodium nitrate and water in an ice bath at 0°C, slowly adding potassium permanganate and reacting at a constant temperature for 1.5 hours to obtain a mixed solution;

[0046] (3) The above mixed solution was placed in an oil bath at 100°C, and after constant temperature reaction for 0.5h, hydrogen peroxide was added to remove the oxidant residue;

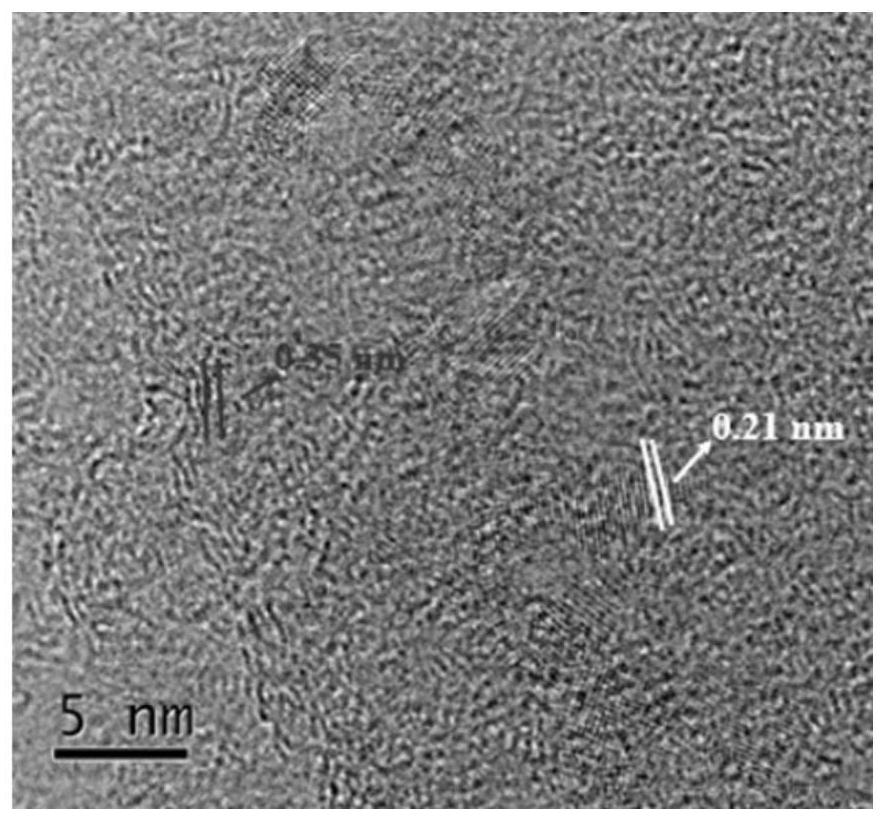

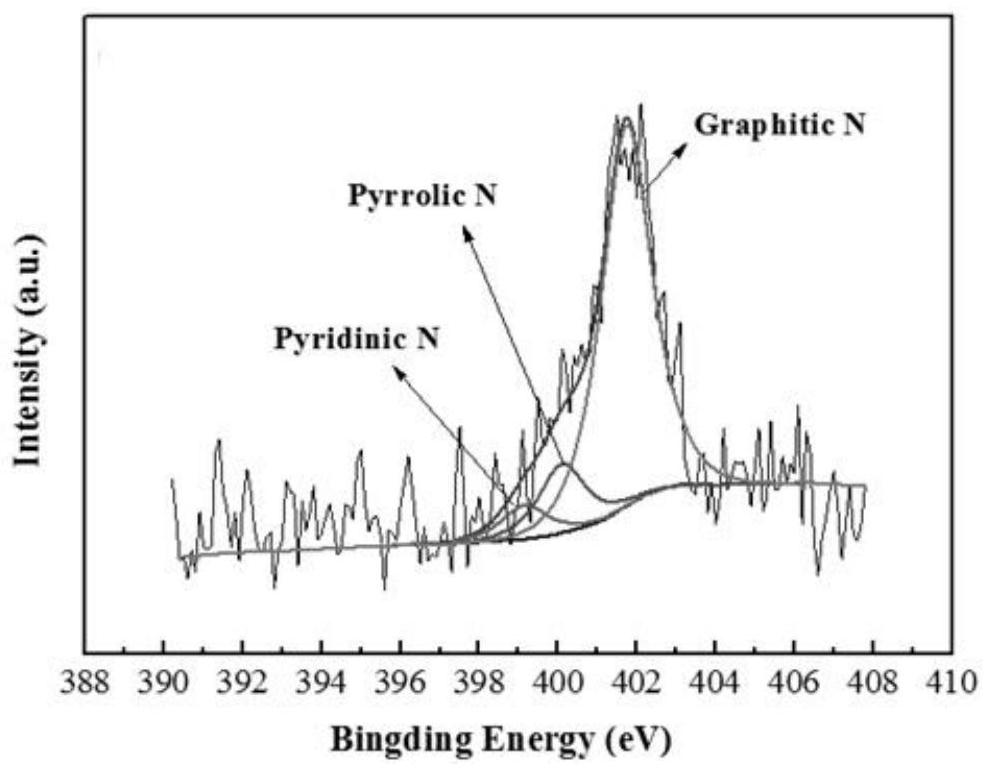

[0047] (4) stirring the material obtained in step (3) at room temperature, slowly adding nitrite and hydrogen peroxide, fully ...

Embodiment 2

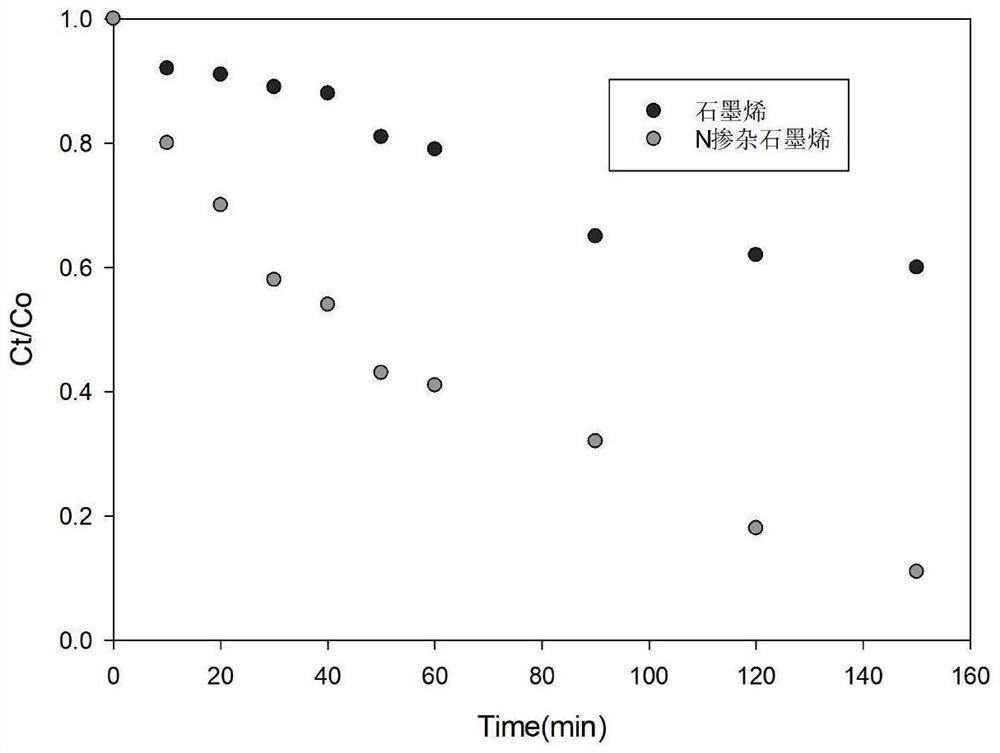

[0050] The electrocatalytic activity test was carried out on the free radical-induced graphite-type nitrogen-doped graphene catalytic material prepared in Example 1, and the electrocatalytic degradation of paracetamol was carried out using a constant potential galvanometer.

[0051] Add 200mL of 10mg L to a 250mL beaker -1 The prepared paracetamol solution and 0.2g NaCl were used as electrolytes; the prepared heteroatom doped graphene material was fixed on 2.5cm with conductive glue 2 on the carbon cloth, used as the anode after drying; the cathode is 2.0cm 2 copper sheet. Turn on the current meter switch and set the initial current. The electrocatalytic process was continuously stirred with a magnetic stirrer, and 1 mL of water samples were collected at specified time intervals, placed in a 2 mL centrifuge tube, and 1 mL of methanol was added to quench free radicals. Use 0.22μm organic filter membrane to filter the water sample, then use 2998PDA (246nm) high performance li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com