Combined type dry method horizontal sorting machine

A composite dry method and sorting machine technology, which is used in solid separation, chemical instruments and methods, and separation of solids from solids by air flow, can solve problems such as low sorting accuracy, and achieve the elimination of the lower limit of sorting, Conducive to the sorting accuracy and the effect of extending the lateral distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

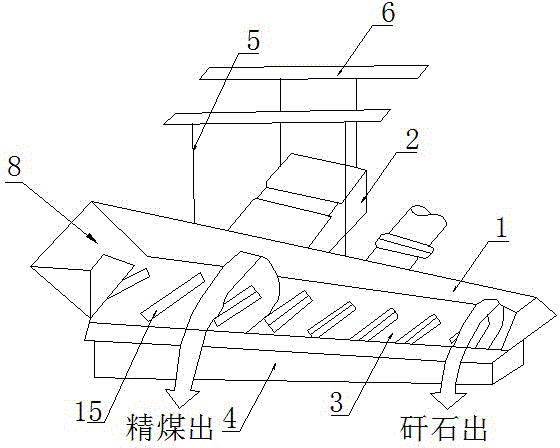

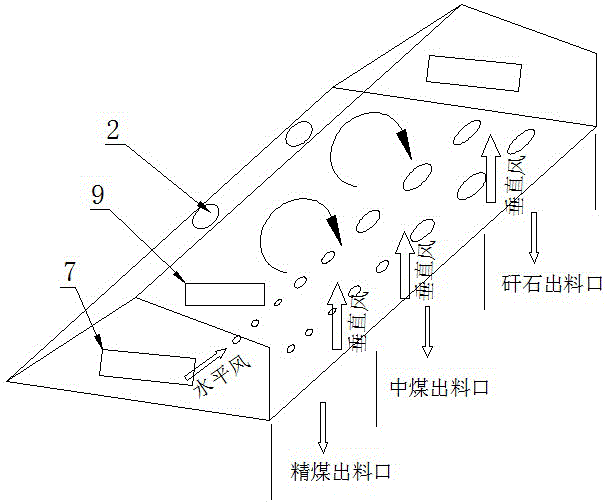

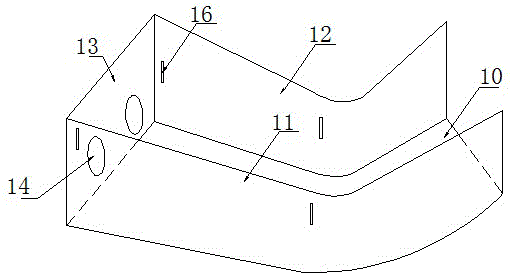

[0013] combine figure 1 , it is not difficult to see that this composite dry horizontal separator is the same as the existing composite dry horizontal separator, including a sorting bed 1, an electromagnetic device installed at the rear end of the sorting bed 1 for vibrating the sorting bed 1 The vibrator 2 is arranged below the bed surface 3 of the sorting bed 1 so that the air flow passes through the air holes uniformly arranged on the bed surface 3 to act on a plurality of air chambers 4 for sorting materials, and the sorting bed 1 and the electromagnetic vibrator 2 are both Installed on the frame 6 through the hanging device 5, combined with figure 2 It can be clearly seen that a horizontal air duct 7 is arranged below the bed surface 3, which opens from one end of the sorting material inlet 8 of the bed surface 3 and extends longitudinally toward the end of the bed surface 3, and communicates with a plurality of air chambers 4, so that Firstly, the horizontal wind force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com