Coated yarn for harness protection

A coating and yarn technology, applied in the field of coated yarn for wire harness protection, can solve the problems of high or low temperature resistance, poor chemical resistance, inconvenient use, large occupied area, etc., and achieve long service life and easy installation Convenience and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

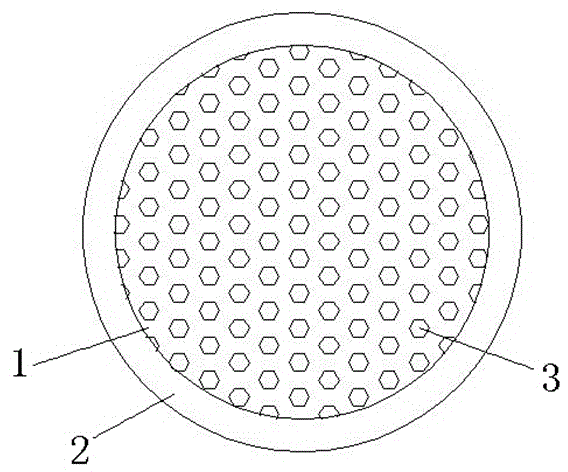

[0018] A coated yarn for harness protection, having a structure such as figure 1 As shown, it consists of a wire core 1 and a coating 2 covering the wire core 1 .

[0019] The wire core 1 is composed of a large number of core wires 3; the core wire 3 is polyester wire; the coating 2 is polyvinyl chloride; the number of the core wires is not less than 10; the diameter of the wire core 1 is is 0.7mm; the thickness of the coating 2 is 0.2mm.

[0020] The coated yarn for wire harness protection in this embodiment is woven into a braided wire layer covering the outside of the wire. The braided wire layer has a staggered structure, which is not affected by the external temperature and has a wide range of applications; it has a compact structure, a small footprint, and a long service life. Long; the material is wear-resistant, high and low temperature resistant. The braided wire layer has tiny gaps, so it has good heat dissipation, soft and waterproof, and will not retain particula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com