Pre-deoxygenation method and device for spraying blowing of carbon powder in tapping hole of converter

A technology of pre-deoxidation device and taphole, which is applied in the field of iron and steel metallurgy, can solve the problems of poor deoxidation dynamics, carbon powder cannot achieve deoxidation effect, and carbon powder density is small, so as to achieve cheap price, save deoxidation cost, and strong The effect of deoxygenation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

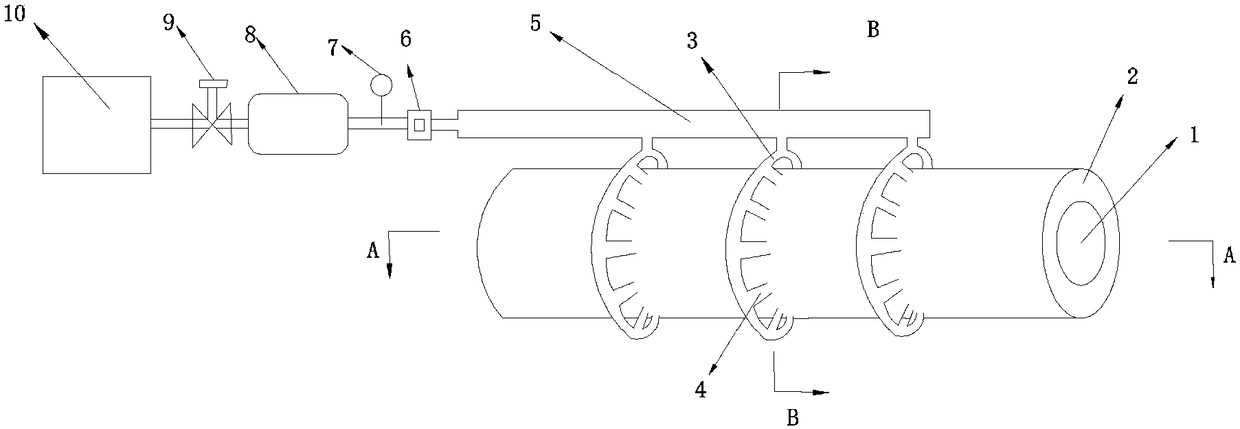

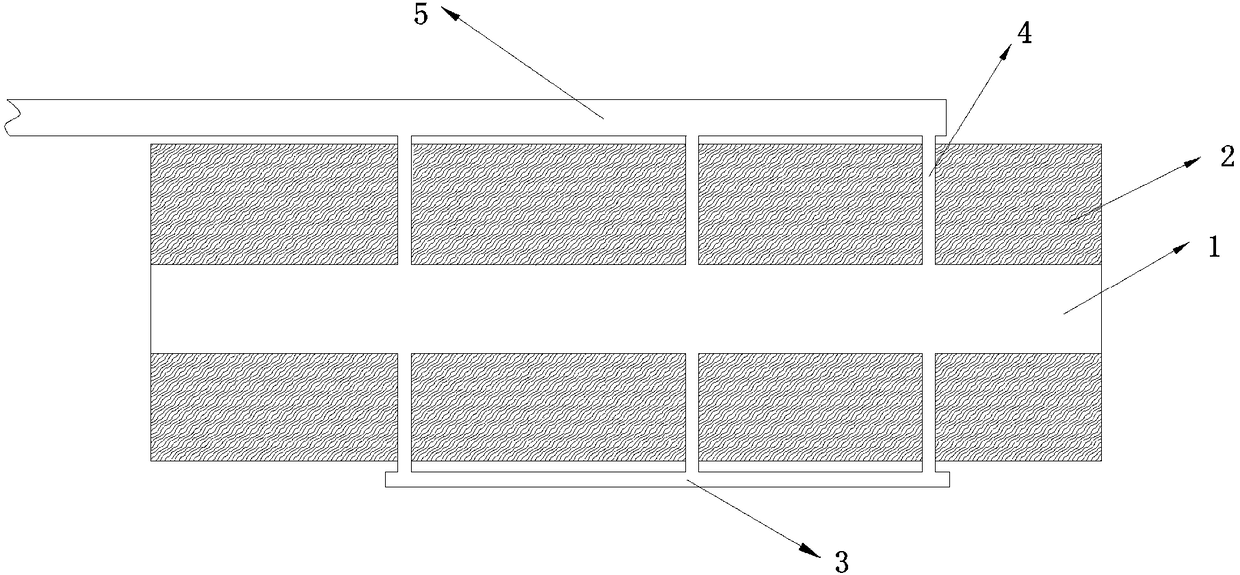

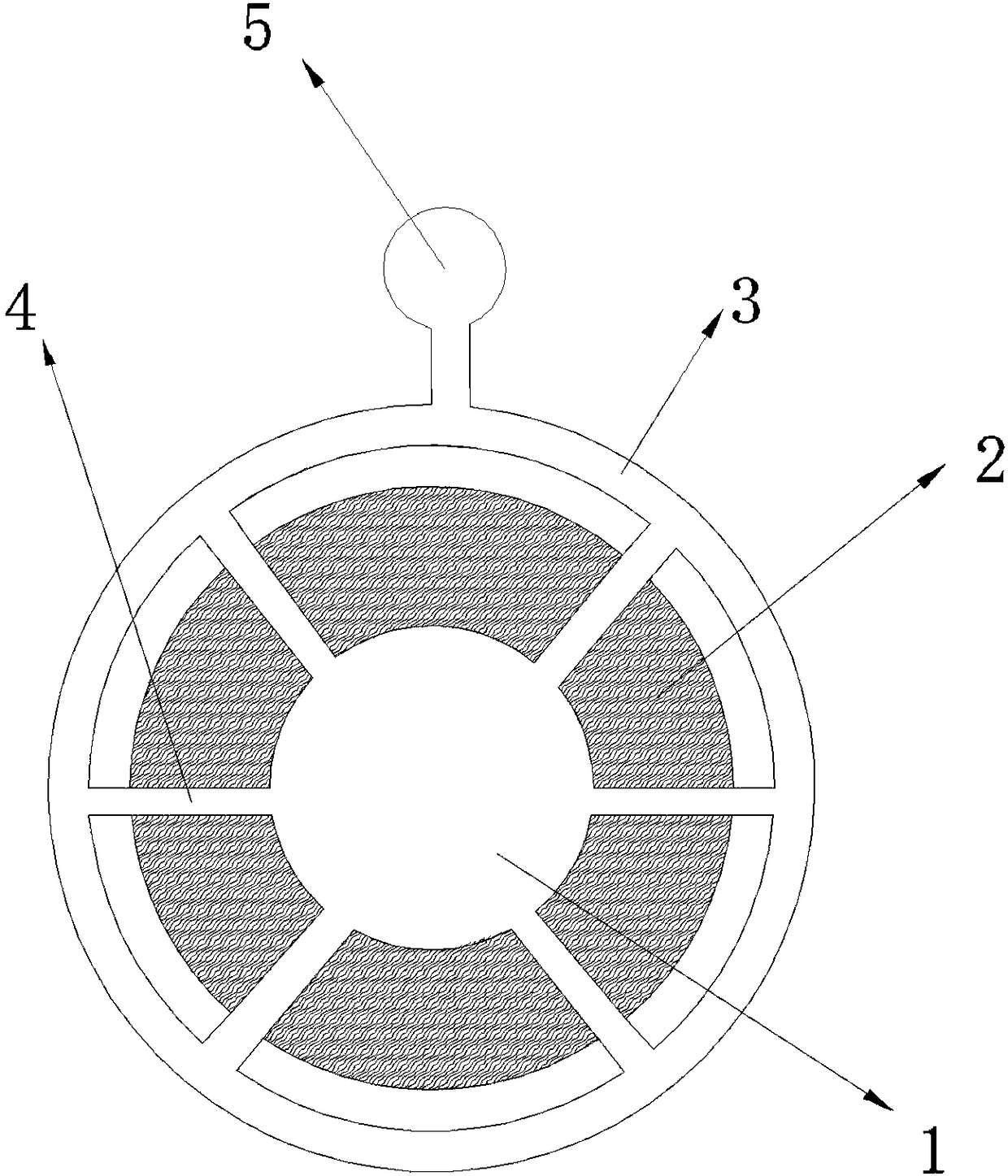

[0047] press figure 1 , figure 2 , image 3 As shown, a total channel 5 for carbon powder injection is arranged in the direction parallel to the tapping port. The internal diameter of the total channel 5 for carbon powder injection is Φ30mm, and the material is steel. The total channel 5 is connected to the powder spraying system 10 through the flow meter 6, the pressure gauge 7, the buffer gas tank 8, and the valve 9. There are 4 groups of ring-shaped carbon powder channels 3 arranged around the steel outlet. The inner diameter of the ring-shaped carbon powder channel 3 It is Φ15mm and made of steel. All the annular toner channels 3 are connected to the general channel 5 for carbon powder injection, and each group of toner channels 3 are connected with 8 inlay and tapping refractory materials The inner diameter of the carbon powder nozzle 4 in 2 is Φ5mm, and the material is steel.

[0048] When it is necessary to replace the tapping port, install the tapping port with the carb...

Embodiment 2

[0062] press figure 1 , figure 2 , image 3 As shown, a total channel 5 for carbon powder injection is arranged in the direction parallel to the tapping port. The internal diameter of the total channel 5 for carbon powder injection is Φ20mm, and the material is steel. The total channel 5 is connected to the powder spraying system 10 through the flow meter 6, the pressure gauge 7, the buffer gas tank 8, and the valve 9. Two groups of ring-shaped carbon powder channels 3 are arranged around the steel outlet. The inner diameter of the ring-shaped carbon powder channel 3 It is Φ13mm and the material is steel. All the ring-shaped toner channels 3 are connected to the total channel 5 for carbon powder injection, and each group of toner channels 3 are connected with 5 inlay and tapping refractory materials The inner diameter of the carbon powder nozzle 4 inside 2 is Φ6mm, and the material is steel.

[0063] When it is necessary to replace the tapping port, install the tapping port wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com