Soil screening device with soil crushing function

A function and soil sieving technology, which is applied in the direction of sieving, solid separation, grid, etc., can solve the problem of fine soil that cannot be sieved into smaller particle sizes, and achieves improved filtration efficiency, reduced work intensity, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

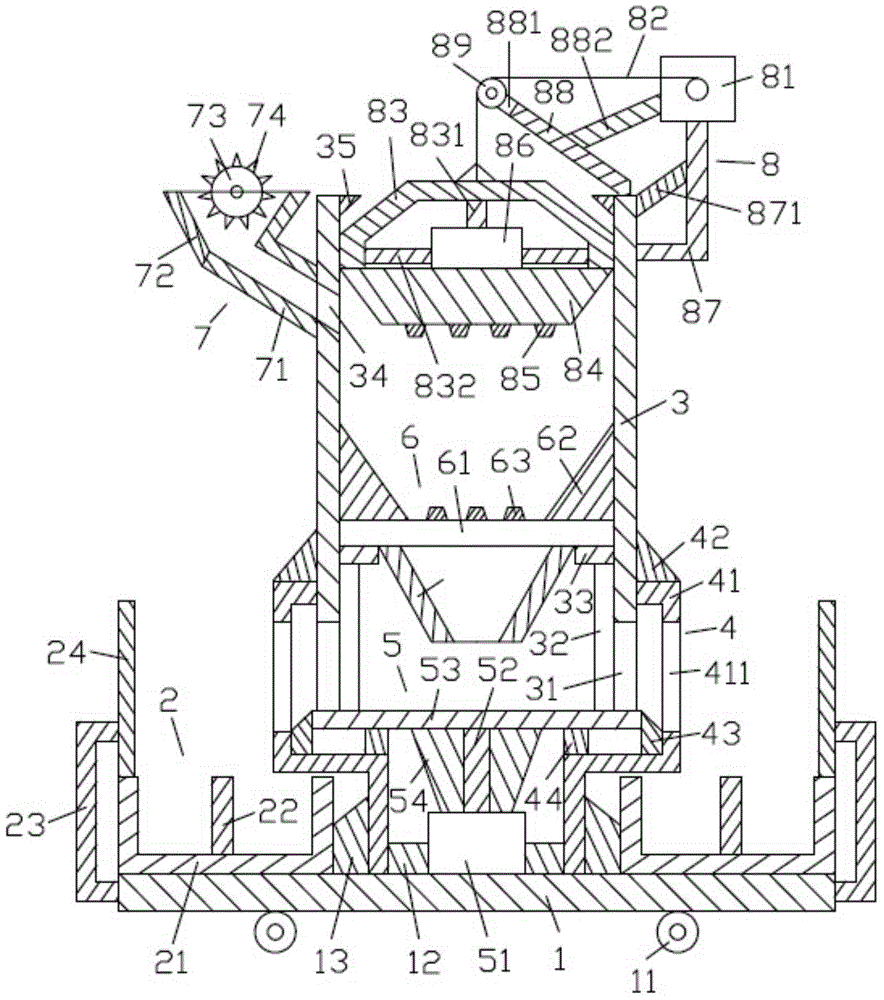

[0019] Such as figure 1 As shown, the soil screening device with the function of crushing soil of the present invention includes a bottom plate 1, a recovery device 2 located above the bottom plate 1, a frame 3 located above the recovery device 2, and a frame 3 located on the left and right sides of the frame 3. The bracket device 4, the first motor device 5 positioned above the bottom plate 1, the filter device 6 positioned above the first motor device 5, the feed device 7 positioned on the left side of the frame body 3 and the frame body positioned on the left side 3 on the second motor unit 8.

[0020] Such as figure 1 As shown, the base plate 1 is a cuboid, and the base plate 1 is placed horizontally. The base plate 1 is provided with a roller 11, a first fixed block 12 located above the roller 11 and a first fixed block 12 located outside the first fixed block 12. The second fixed block 13. There are two rollers 11 located on the left and right sides respectively, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com