A kind of molten iron pretreatment desiliconization/dephosphorization agent and using method thereof

A technology of hot metal pretreatment and dephosphorization agent, which is applied in the field of hot metal pretreatment desiliconization/dephosphorization agent, can solve the problems of inability to guarantee desulfurization and dephosphorization efficiency, high viscosity of desiliconization slag, and low utilization amount of red mud, etc. Improve kinetic conditions, take into account the requirements of desiliconization and dephosphorization, and improve the effect of desiliconization and dephosphorization requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

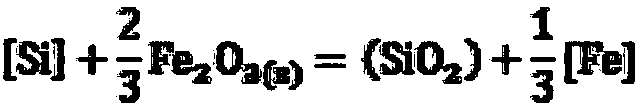

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: Preparation of desiliconization / dephosphorization agent

[0046] The red mud produced by the Bayer method of a domestic aluminum plant was selected, and the iron element in it was purified and enriched by magnetic separation to obtain high-iron red mud. The main components of high-iron red mud are shown in Table 1:

[0047] Table 1 Main components in high-iron red mud

[0048] Element

[0049] After the high-iron red mud is dried, it is uniformly mixed with lime particles (particle size ≤ 3mm) at a mass ratio of 1:0.25 to make a desiliconization / dephosphorization agent. The overall particle size of the desiliconization / dephosphorization agent is required to be ≤3mm. Among them, The content of the desiliconization / dephosphorization agent with a particle size of 1-3mm is ≤5wt%, so as to facilitate the transportation and feeding of the desiliconization / dephosphorization agent. Transport by tank truck.

Embodiment 2

[0050] Embodiment 2: the use of desiliconization / dephosphorization agent

[0051] According to the requirements of steelmaking and smelting steel types and the conditions of molten iron entering the station, it is determined whether to carry out desiliconization operation, dephosphorization operation or both operations.

[0052] If molten iron [Si]≥0.40%, desiliconization operation is carried out, according to the target desiliconization amount, add desiliconization / dephosphorization agent to the molten iron, the relationship between the amount of desiliconization / dephosphorization agent added and the target desiliconization amount for:

[0053] Y 1 =131.2X 1 ;

[0054] In the formula, Y 1 Represents the amount of desiliconization / dephosphorization agent added (kg / t), X 1 Represents the target desiliconization amount (X 1 %).

[0055] Select several target desiliconization amounts, see Table 2 for the amount of desiliconization / dephosphorization agent added, and reduce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com