Novel bumping-and-pressing-type float collar

A technology of bumping pressure and floating hoop, applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of low reliability, erosion resistance, low pressure bearing capacity, etc., and achieve the overall structure Reasonable design, solving the effect of high temperature resistance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0025] The present invention will be described in detail with reference to the accompanying drawings and examples.

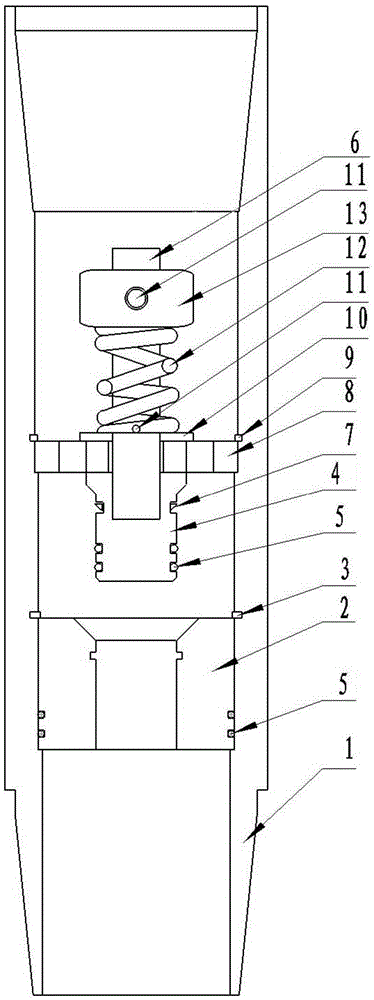

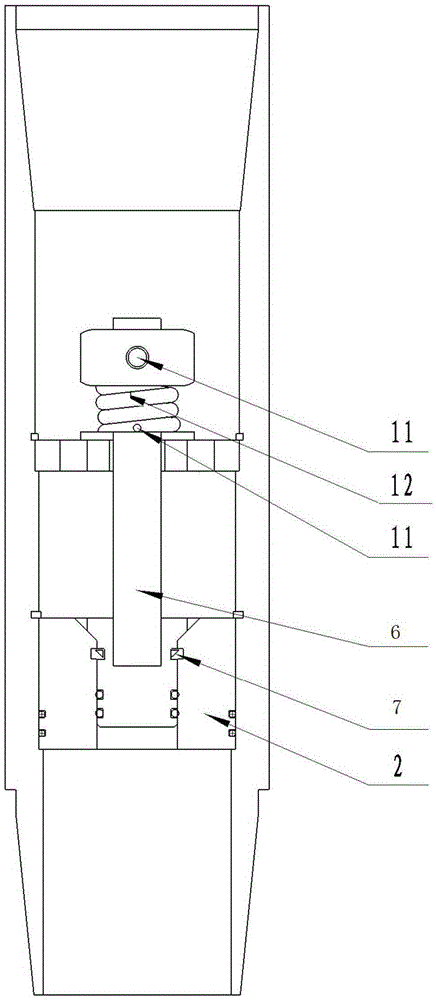

[0026] A new type of bumper floating hoop, such as figure 1 , 2 As shown, it includes a floating hoop body 1, and the inner cavity of the floating hoop body 1 is provided with a bump seal seat body 2, a sealing insert 4, a sealing insert core rod 6, an overflow plate 8 and a spring 12 from bottom to top. ;

[0027] The overflow plate 8 is installed in the middle of the inner cavity of the floating hoop body 1, and the limiting structure of the overflow plate 8 is provided in the inner cavity of the floating hoop body 1. In this embodiment, the overflow plate limiting snap ring 9 is used. To limit the position, the sealing insert core rod 6 passes through the central hole of the overflow pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com