A Coal Mining Method for F-shape Sections Realizing Coal Pillar Coal Mining

A coal mining method and section technology, which is applied in the field of simultaneous recovery of underground solid coal and section coal pillars, can solve the problems of one-time mining of difficult-to-protect coal pillars, complex recovery construction technology, and low resource recovery rate, and achieve resource mitigation. The effect of conflicting with society, reducing safety production accidents, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

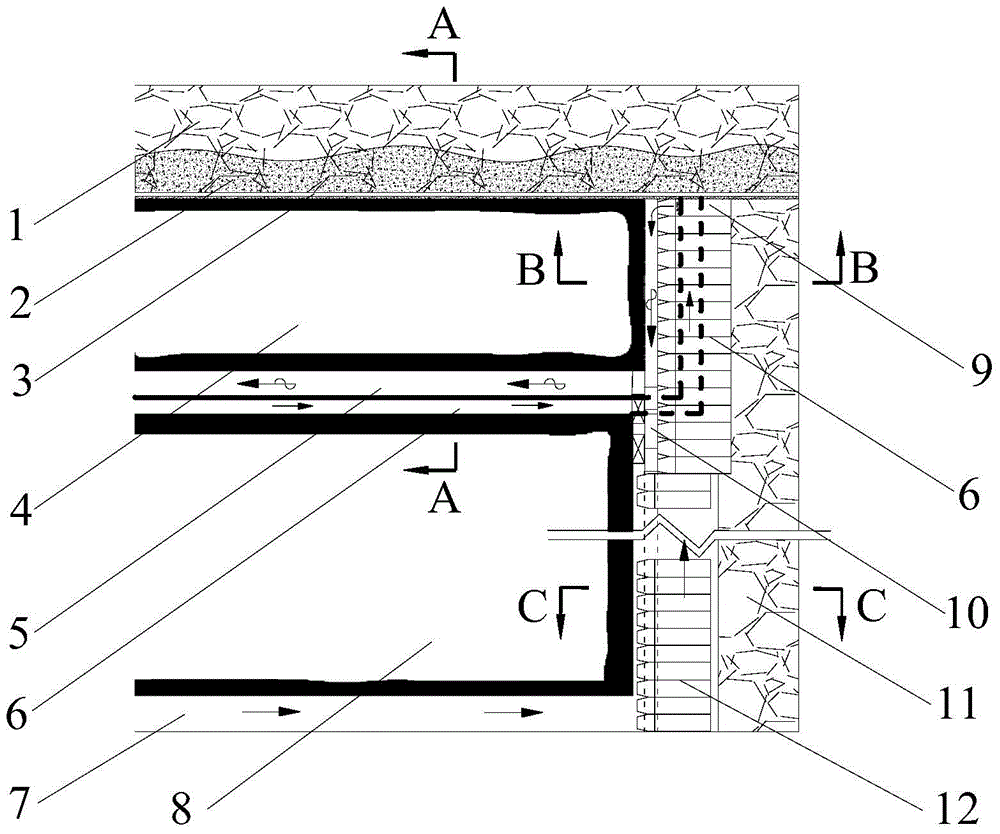

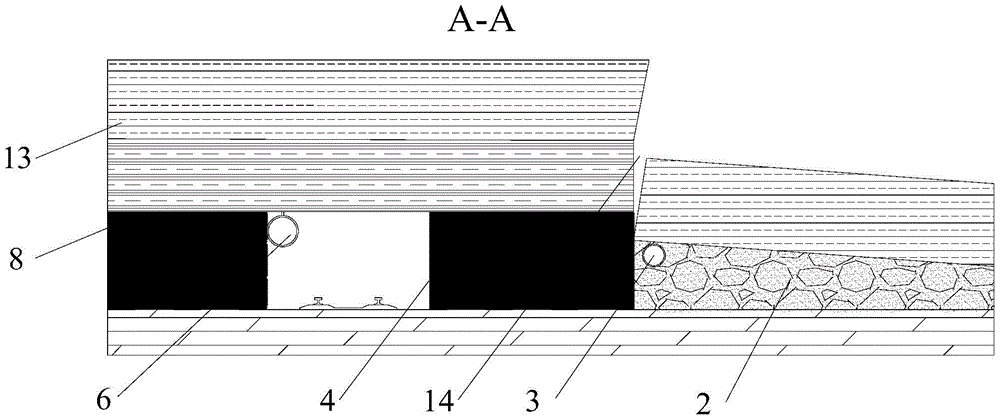

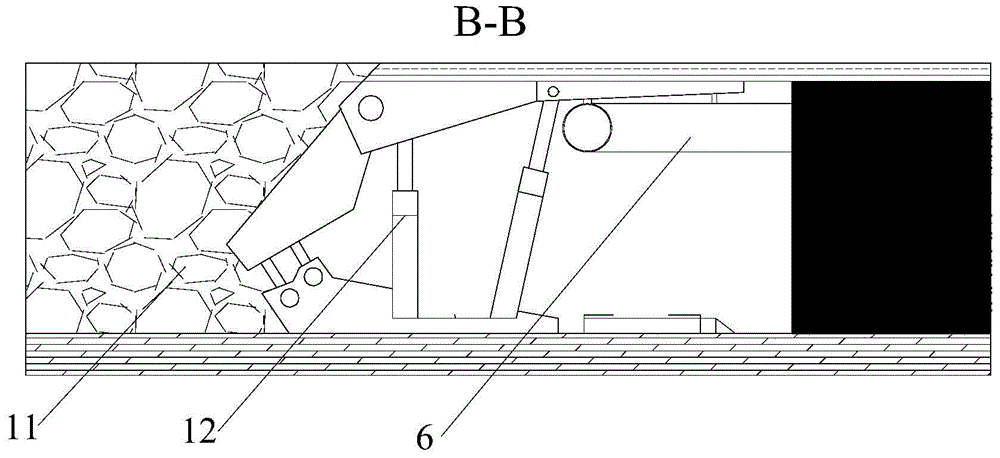

[0012] Such as figure 1 A schematic diagram of the overall structure of an F-shaped section coal mining method that realizes simultaneous mining of coal pillars, including: upper section goaf 1; filling paste 2; filling grouting pipeline 3; section protection coal pillar 4 ; air return lane 5; flexible ventilation pipe 6; air inlet lane 7; solid coal 8; air outlet 9; coal mining machine 10; goaf 11; hydraulic support 12;

[0013] A kind of F-type section coal mining method that realizes coal pillar simultaneous mining of the present application, it is mainly to carry out corresponding recovery simultaneously with the upper section protection coal pillar 4 of air return roadway while reclaiming solid coal 8, at this moment The coal mining face is divided into two parts, wherein a part is the solid coal mining face, and the other part is the coal pillar mining face; Install the corresponding hydraulic support 12 so that it can protect the entire mining face accordingly; during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com