Bolt positioning structure

A bolt positioning and bolt technology, applied in the directions of bolts, screws, nuts, etc., can solve the problems of inability to complete the assembly content, detachment, bolt positioning, etc., and achieve the effect of simple structure, high structural stability and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

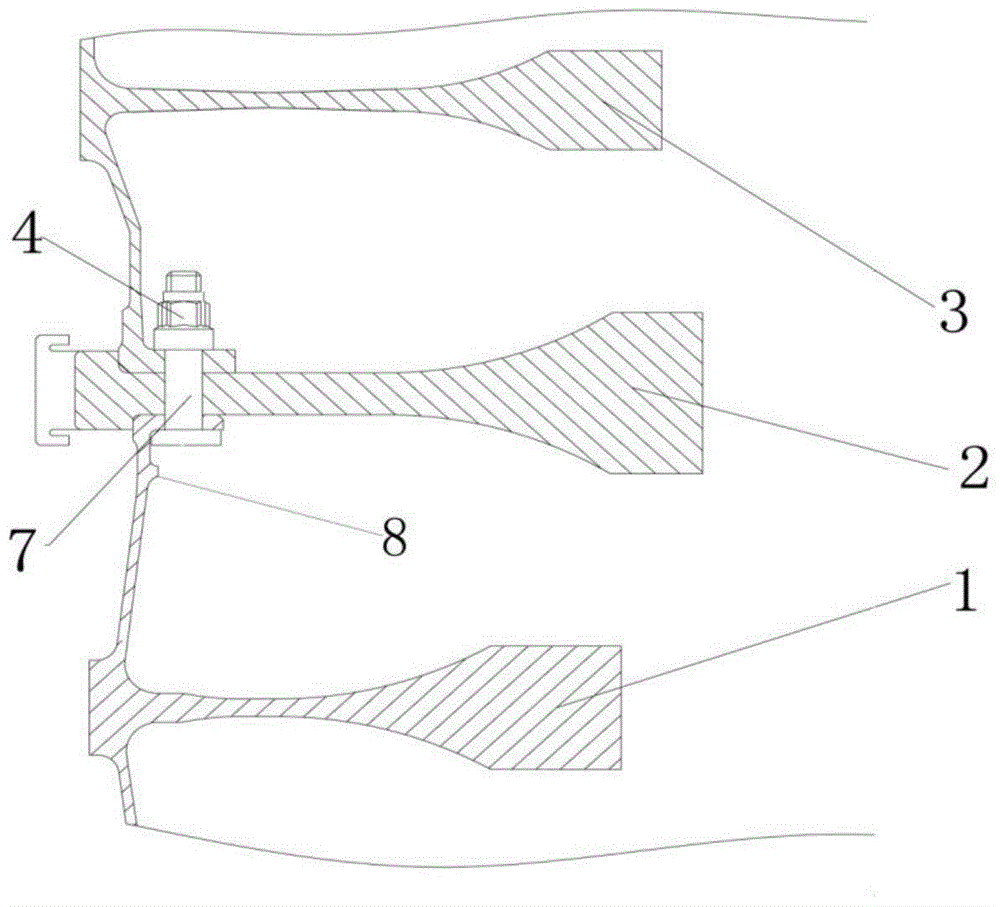

[0017] Such as figure 1 As shown, the bolt positioning structure provided by the present invention includes a first part 1, a bolt 7, and a nut 4. The bolt 7 passes through the installation edge of the first part 1, and cooperates with the nut 4 to connect the first part 1 with the nut 4. Other parts are fixedly connected, wherein a boss 8 is set on the inner wall of the first part 1, and the head of the bolt 7 is placed between the mounting edge of the first part 1 and the boss and overlapped on the boss 8 . Nut 4 is a self-locking nut. If it is inconvenient to use the self-locking nut during use,

[0018] The screw rod of the bolt 7 is composed of a polished rod part and a threaded rod part, wherein the polished rod part is arranged between the head of the bolt 7 and the threaded rod, and the length of the polished rod part is the installation side of the first part 1 and the installation side of other parts the sum of the thicknesses. The head of the bolt 7 is set to a ...

Embodiment 2

[0024] Referring to the above-mentioned embodiment 1, the difference lies in that this embodiment replaces the self-locking nut by the following scheme: a washer is arranged between the nut 4 and the other parts. The screw rod of the bolt 7 is provided with an anti-rotation groove, and a retaining ring is arranged in the anti-rotation groove, and the distance between the washer and the retaining ring is the same as the thickness of the nut. In this embodiment, the nut 4 can be either a self-locking nut or an ordinary nut.

[0025] The above two embodiments show that three parts are connected, but, according to the above embodiments, those skilled in the art can understand that the number of parts connected can be changed according to different actual situations, and can be two parts or more Component. The above-mentioned "other parts" refer to not only one part, but also multiple parts.

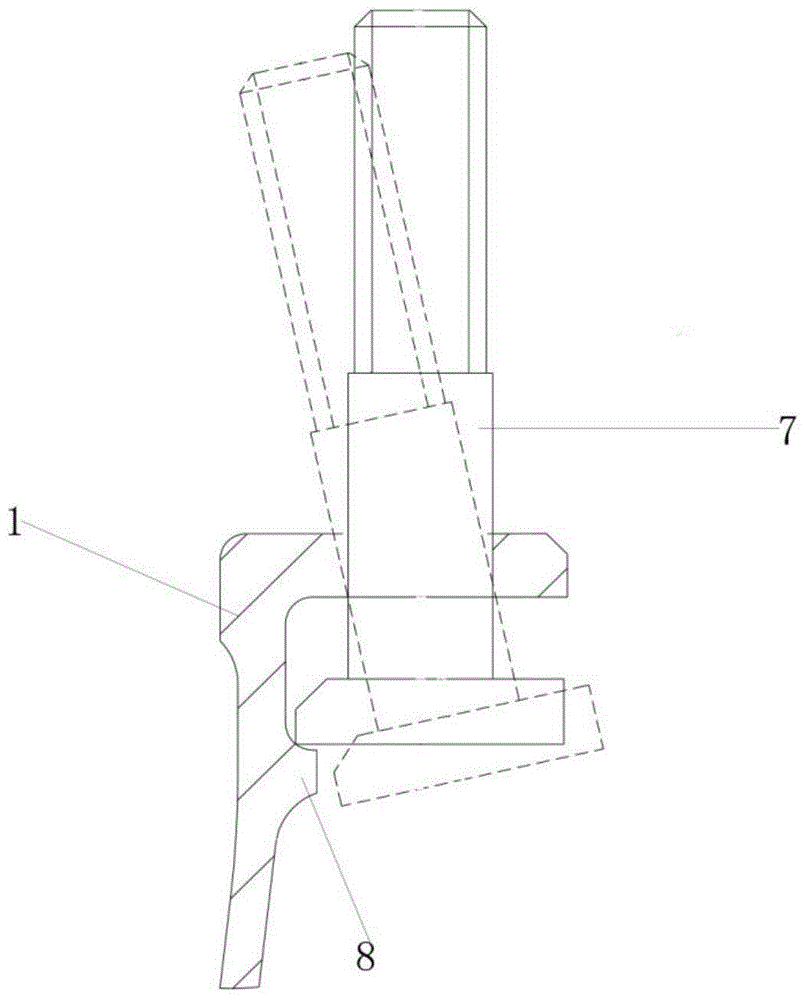

[0026] figure 2 Shown is the process of inserting the bolt 7 into the bolt hole on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com