Energy-saving controller of electromagnetic valve

A solenoid valve and controller technology, applied in valve details, valve operation/release devices, valve devices, etc., can solve problems such as energy waste and power consumption, and achieve the effect of extending service life, protection and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

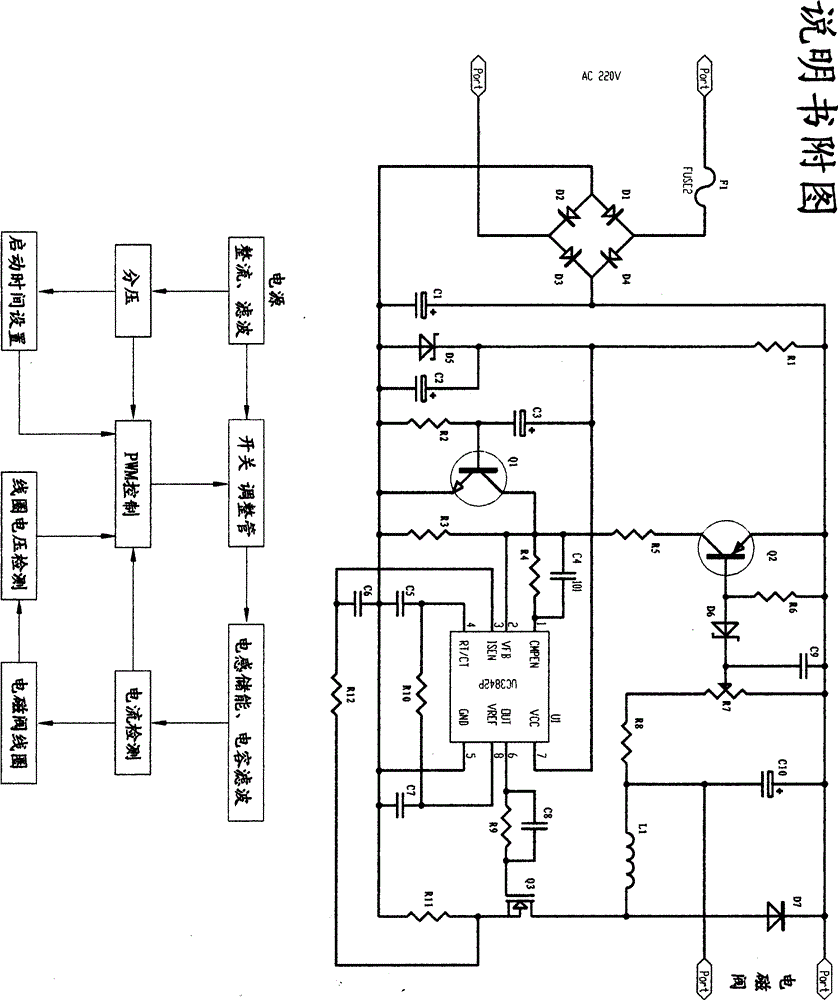

[0015] As shown in the figure, with diode D 1 -D 4 The input voltage is bridge rectified, and then through the capacitor C 1 The input peak DC voltage obtained after filtering (to ensure sufficient electromagnetic suction in the early stage of the solenoid valve closing), the power supply is controlled by the resistor R 1 shunt, Zener diode D 5 regulator, capacitor C 2 After filtering, it is used by PWM chip UC3842 and start-up delay circuit. Capacitance C 3 , resistor R 2 , Transistor Q 3 Form a start-up delay circuit to ensure that the solenoid valve has sufficient electromagnetic suction when it starts. After the set delay time, the PWM chip UC3842 automatically enters the energy-saving state (according to the model of the solenoid valve, adjust R 7 , so that the voltage across the solenoid valve coil can be stabilized at an appropriate value). Change the resistor R 10 and capacitance C 5 , can change the oscillation frequency of the PWM chip UC3842. Adjust resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com