Boiler automatic combustion adjustment control method based on coal-air ratio coal quality correction

A control method and automatic combustion technology, which are applied in the combustion method, control combustion, and adjust the air supply, etc., can solve the problems of complex structure, high cost, and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific implementation mode one: the boiler automatic combustion adjustment control method based on air-to-coal ratio coal quality correction of the present embodiment, it is realized according to the following steps:

[0032] (1) Through the standard coal combustion test of the angle-fired boiler, the ratio of the air volume to the coal volume under different power generation corresponding to different oxygen amounts, referred to as the air-to-coal ratio, is used as the benchmark air-to-coal ratio;

[0033] (2) Through the logical configuration of the distributed control system, the timing detection and result output coal quality correction coefficient K are realized;

[0034] (3) Calculating the expression of feed-forward for each layer of boiler auxiliary air damper for the K value from the coal quality correction coefficient K;

[0035] (4) After adding the general expression of each layer’s feedforward K value calculated in Step 3 into the original control loop, t...

specific Embodiment approach 2

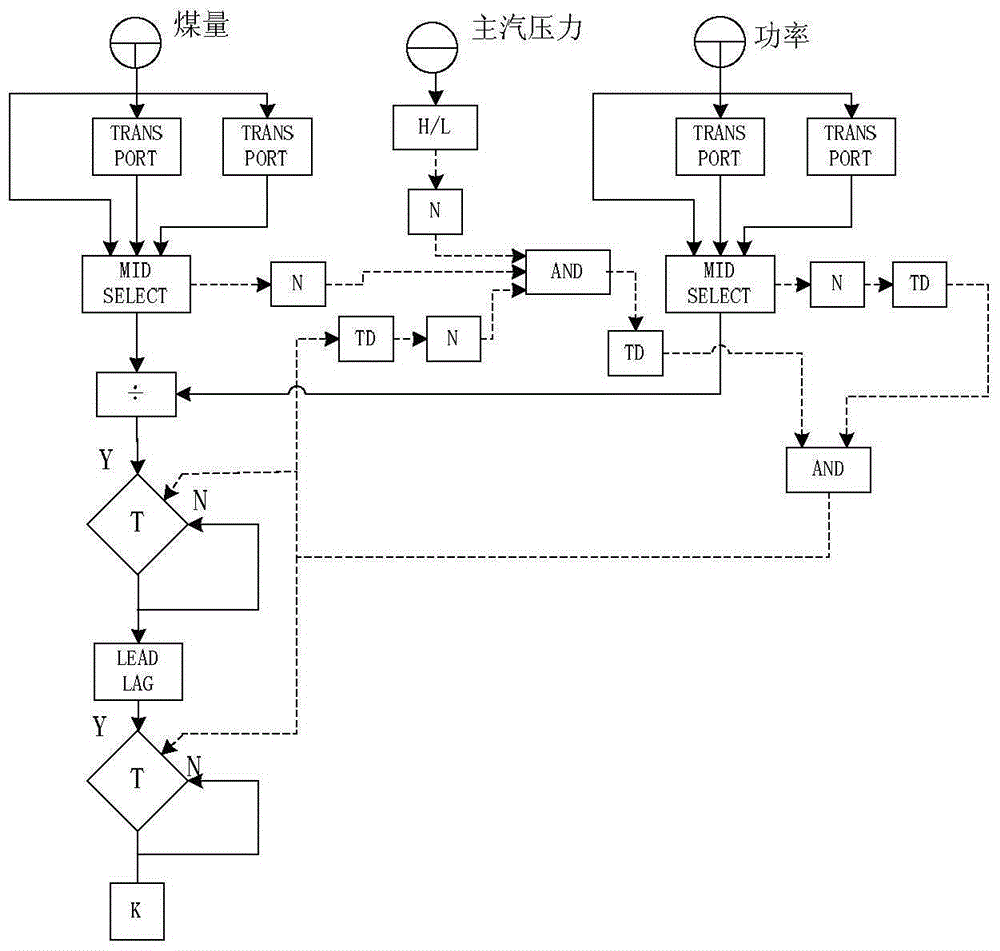

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is that step (2) realizes timing detection and result output coal quality correction coefficient K through the logical configuration of the distributed control system, and the specific steps are as follows:

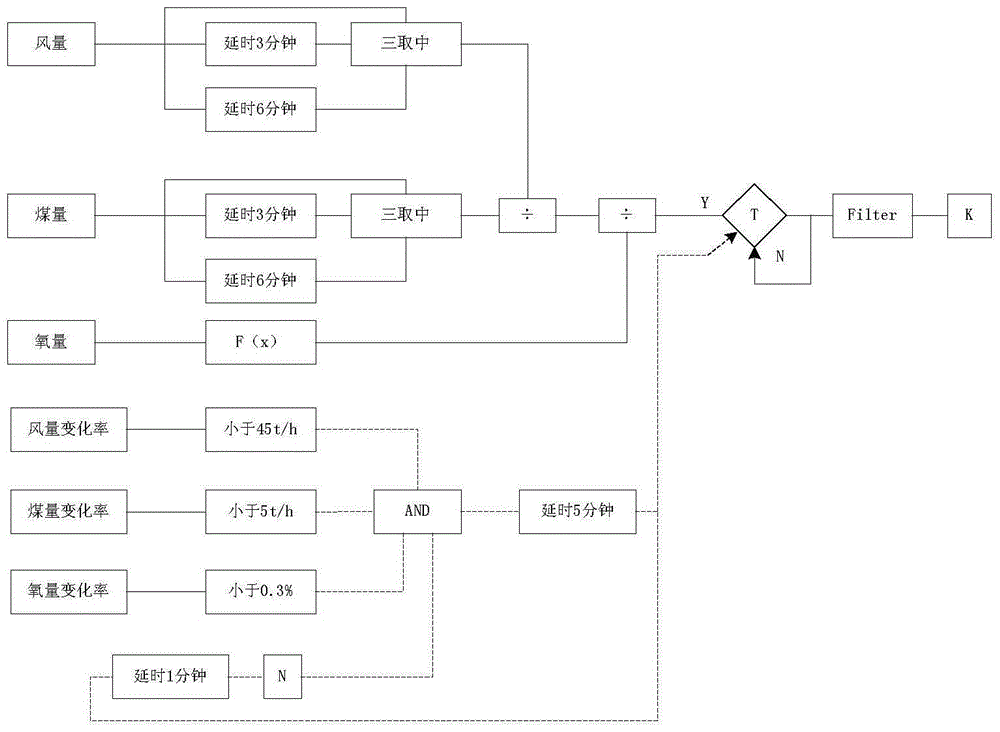

[0037] ① Real-time sampling of air volume and coal volume by power plant sensors, real-time calculation of the current air-to-coal ratio, and dividing by the benchmark air-to-coal ratio in (1) to obtain a process variable, defined as K 1 ;

[0038] ②Define the boiler stable combustion state judgment parameter as S. In the logic configuration, the total air volume, total coal volume and oxygen volume of the boiler are differentiated through the inherent sensor to obtain the air volume change rate, coal volume change rate, and oxygen volume change rate. ;

[0039] (a) When the three conditions of air volume change rate less than 45t / h, coal volume change rate less than 5t / h a...

specific Embodiment approach 3

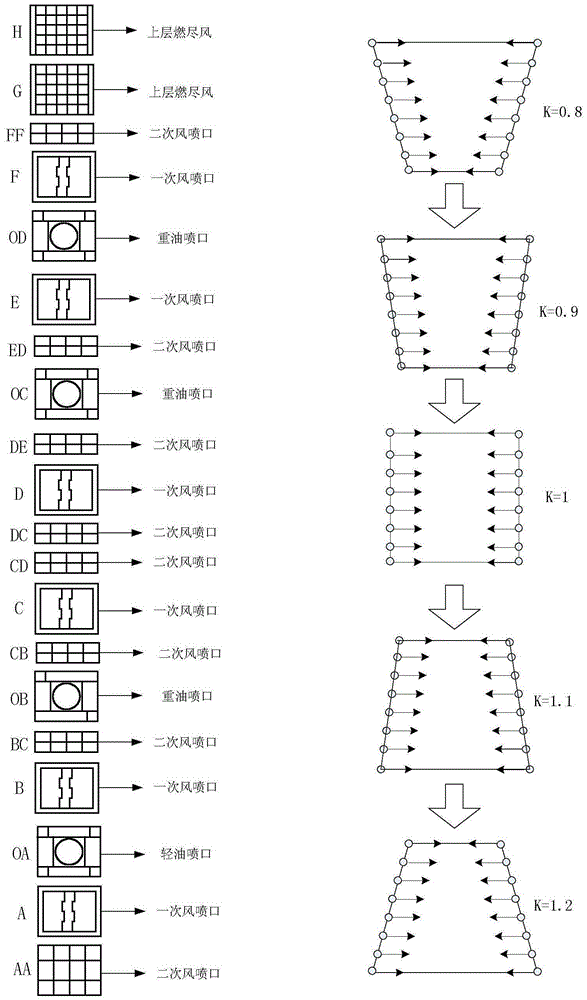

[0045] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: step (3) calculates the general expression of feed-forward for each layer of boiler auxiliary air damper by the coal quality correction coefficient K;

[0046] 1. Set the number of auxiliary damper layers of the original control circuit boiler corner burner as N layers, the bottom layer as the first layer, the top layer as the Nth layer, and the adjustment range is the maximum difference M% between the top layer and the bottom layer; among them, the N is any positive integer;

[0047] 2. When the coal quality correction coefficient is K=m 1 When , the feed-forward of the top layer, that is, the Nth layer is The feed-forward of the bottom layer, the first layer, is set to Each layer in the middle is an arithmetic sequence from small to large, then the feedforward opening of the second layer is The feed-forward opening of layer 3 is Arithmetic series obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com