Base plate structure

A technology for substrates and bonding pads, applied in the direction of static indicators, etc., can solve problems such as bonding pad corrosion, equipment failure, control signal transmission problems, etc., achieve good bonding adhesion, avoid corrosion, and block moisture or oxygen from entering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The structure of the substrate according to the preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference symbols. The illustrations of all the implementation aspects of the present invention are only schematic representations, and do not represent real dimensions and proportions.

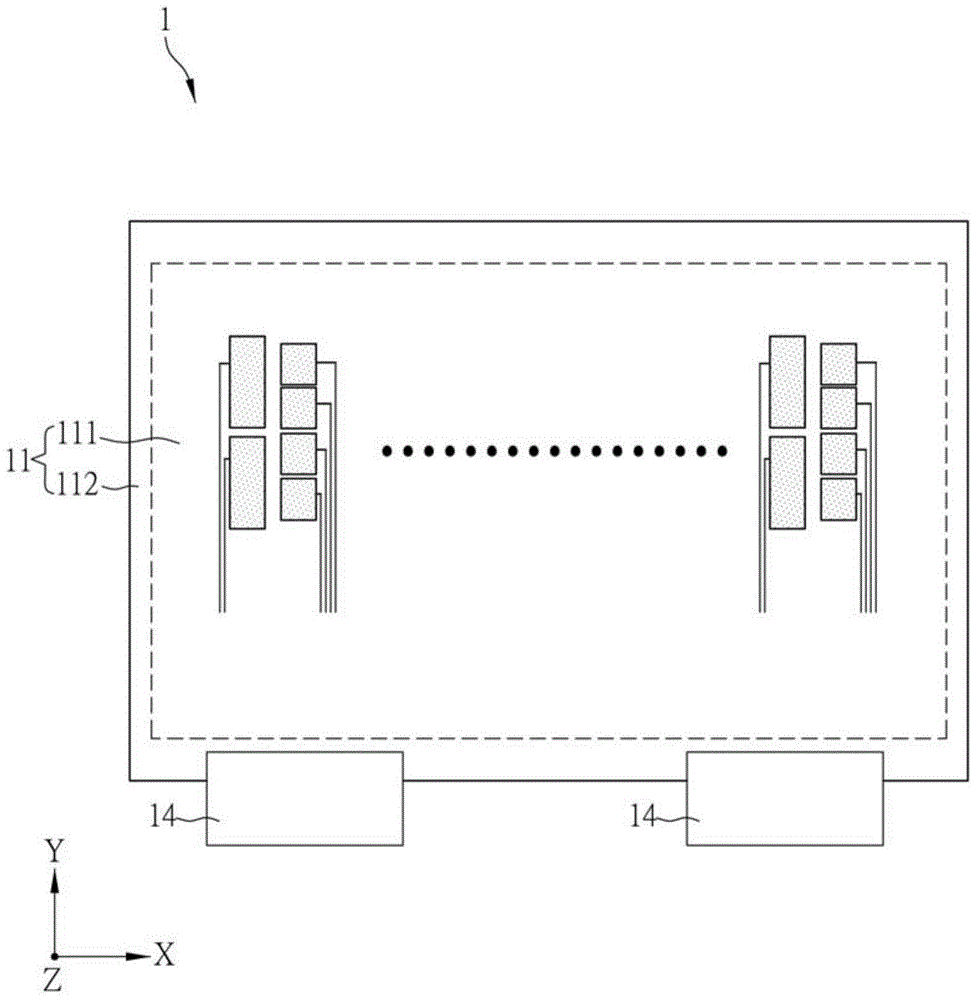

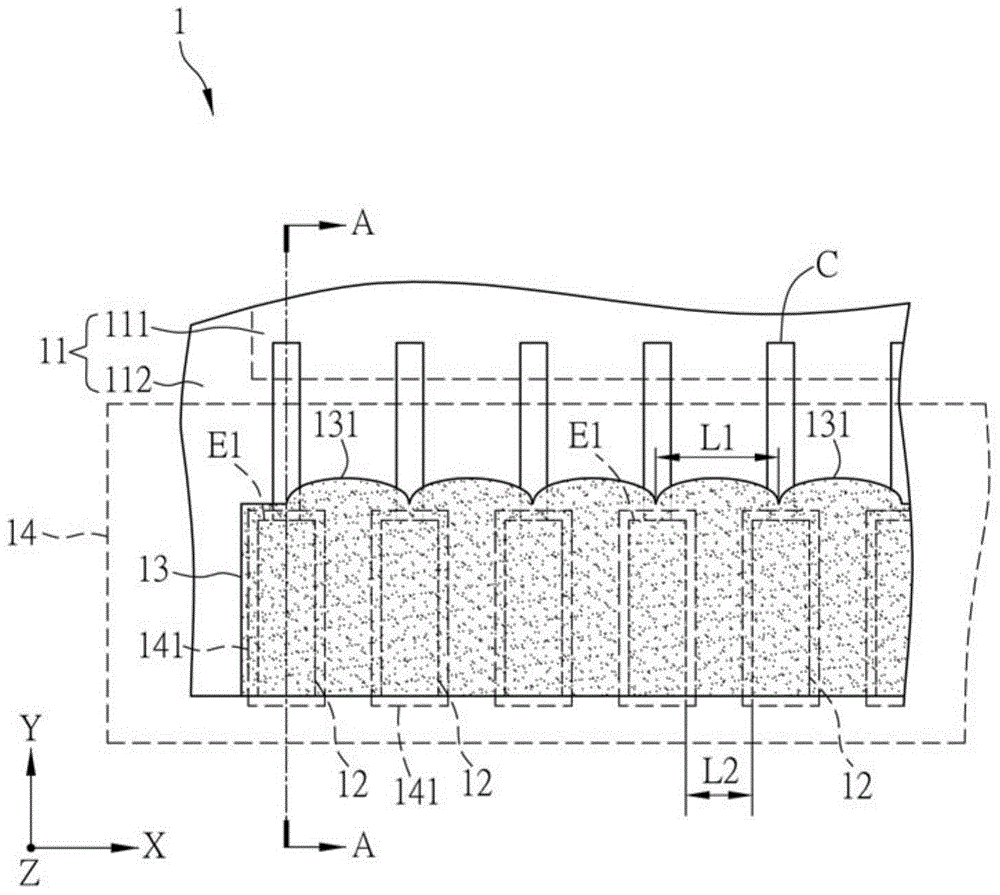

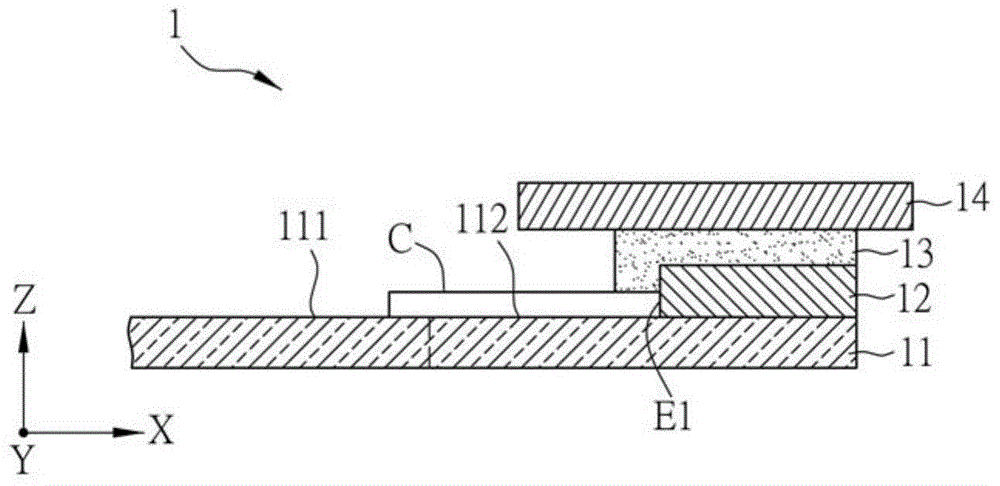

[0040] Please refer to Figure 1A to Figure 1C As shown, among them, Figure 1A It is a schematic top view of a substrate structure 1 in a preferred embodiment of the present invention, Figure 1B for Figure 1A A partially enlarged schematic diagram of the substrate structure 1, while Figure 1C for Figure 1B , the schematic cross-sectional view of line A-A.

[0041] The substrate structure 1 includes a first substrate 11 , a plurality of first bonding pads 12 and a bonding layer 13 . In addition, the substrate structure 1 of this embodiment further includes a second su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com