Method for predicting coke quality and optimizing coal blending ratio for tamping coking

A technology of coke quality and coal blending ratio, applied in forecasting, data processing applications, instruments, etc., can solve problems such as low precision, no consideration of coal blending cost, and inability to improve coke quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

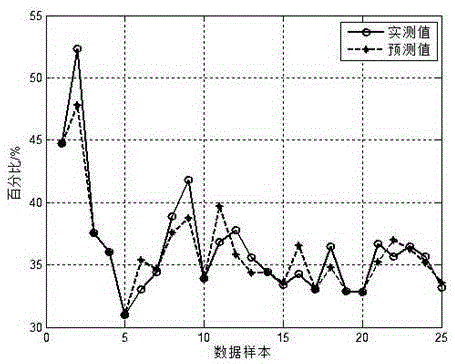

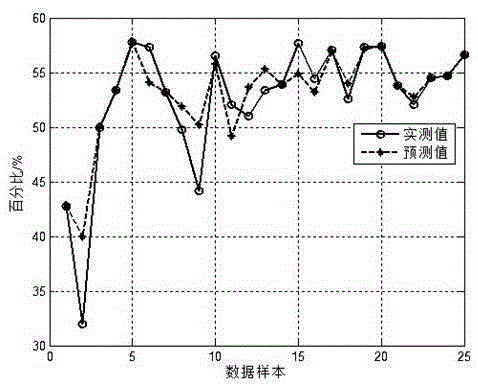

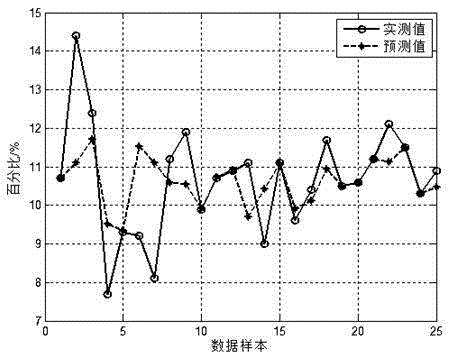

Image

Examples

Embodiment 1

[0155] A method for predicting coke quality and optimizing coal blending ratio for tamping coking. The concrete steps of this method are:

[0156] According to the national standard, the present embodiment analyzes the sulfur content S of 10 kinds of single coals in a coking plant coking coal. i , Ash A d,i , Volatile V daf,i , the average maximum reflectance of vitrinite Live to idle ratio A i / I i The test results and the cost of a single type of coal are shown in Table 1 (the distribution ratio of the vitrinite random reflectance of a single type of coal is not listed in Table 1 due to the large and complex data).

[0157] Table 1 Process properties of single coal

[0158]

[0159] Step 1. Establish a single coal property index database and a coke property index database

[0160] Using the design method of 3NF database in SQLServer large-scale database application technology, a single coal property index database and a coke property index database are established...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com