A method for preparing high-swellable dietary fiber from residue after extraction of mulberry leaves

A technology of dietary fiber and mulberry leaves, which is applied in the field of producing high-swellable dietary fiber, can solve the problems of reduced added value and production wastewater, and achieve the effects of reducing fracture, reducing cost, environmental protection, and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

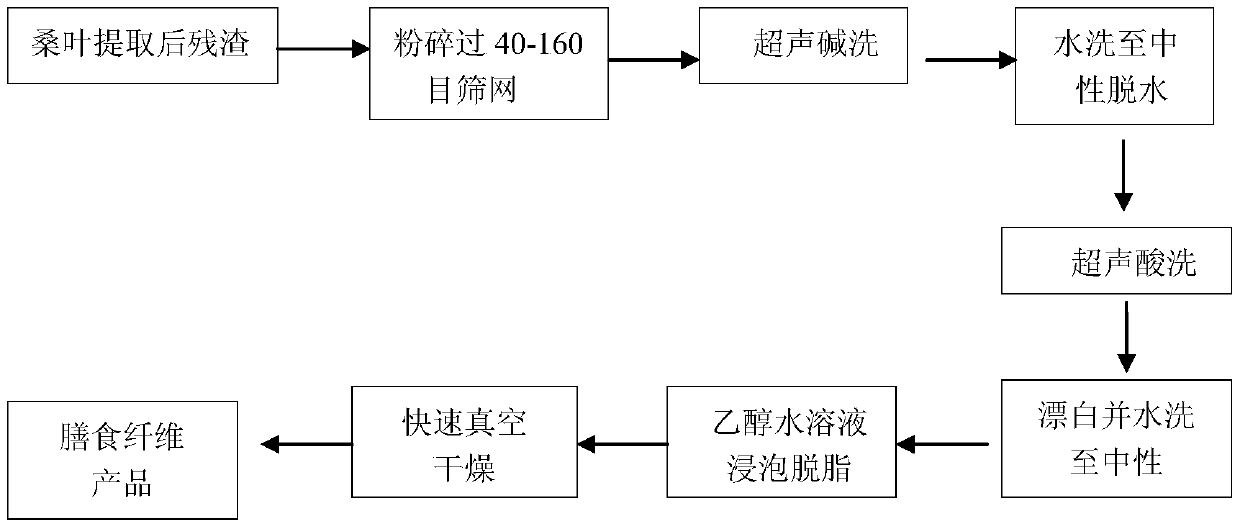

[0033] A method for preparing high-swellable dietary fiber from residues after extraction of mulberry leaves, comprising the following steps:

[0034]1) The mulberry leaf residue after water extraction is dried and crushed through a 40-mesh sieve. Add 5wt% NaOH solution at a ratio of 1:10 (dry weight W / V) and mix evenly. Disperse and stir all around and use a power of 3KW, 20KHz frequency ultrasonic 90min, use a three-legged centrifuge at a speed of 3000rmp for 8min to obtain filter residue;

[0035] 2) After centrifugation, the filter residue is washed with water to neutrality, and centrifuged and dehydrated with a three-legged centrifuge at a speed of 3000rmp for 8 minutes to obtain alkali-washed dietary fiber;

[0036] 3) Add 4wt% hydrochloric acid to the alkali-washed dietary fiber at a ratio of 1:10 (dry weight W / V), control pH = 2, at 80°C, 3000rmp, disperse and stir with 12 knife holes up and down, and use power of 3KW, 20KHz frequency ultrasonic After 60 minutes, use ...

Embodiment 2

[0041] A method for preparing high-swellable dietary fiber from residues after extraction of mulberry leaves, comprising the following steps:

[0042] 1) The mulberry leaf residue after alcohol extraction was dried and crushed through an 80-mesh sieve, then mixed with 4wt% NaOH solution at a ratio of 1:8 (dry weight W / V), mixed evenly, at 70°C, 5000rmp, 18 knife holes up and down Disperse and stir all around, and use a power of 5KW, 15KHz frequency ultrasonic for 60min, and use a three-legged centrifuge at a speed of 3000rmp for 12min to obtain the filter residue;

[0043] 2) After centrifugal filtration, the filter residue is washed with water to neutrality, and centrifuged with a three-legged centrifuge at a speed of 3000rmp for 9 minutes to obtain alkali-washed dietary fiber;

[0044] 3) Add 5wt% hydrochloric acid to the alkali-washed dietary fiber according to 1:8 (dry weight W / V), control the pH=2, at 60°C, 5000rmp, disperse and stir with 18 knife holes, and use power of ...

Embodiment 3

[0049] A method for preparing high-swellable dietary fiber from residues after extraction of mulberry leaves, comprising the following steps:

[0050] 1) After the mulberry leaf residue extracted by water is dried and crushed through a 100-mesh sieve, add 5wt% KOH solution at a ratio of 1:9 (dry weight W / V) and mix evenly. Disperse and stir all around and use a power of 4KW, 18KHz frequency ultrasonic for 45min, and use a three-legged centrifuge at a speed of 3000rmp for 15min to obtain the filter residue;

[0051] 2) After centrifugation, the filter residue is washed with water to neutrality, and centrifuged and dehydrated for 10 minutes at a speed of 3000rmp in a three-legged centrifuge to obtain alkali-washed dietary fiber;

[0052] 3) Add 5wt% hydrochloric acid to the alkali-washed dietary fiber at a ratio of 1:9 (dry weight W / V), control pH = 2, at 70°C, 5000rmp, disperse and stir with 18 knife holes up and down, and use power of 4KW, 18KHz frequency ultrasonic 45min, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com