Two-stage cyclone magnetic dust remover

A dust collector and magnetic generator technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of low purification efficiency, small scope of application, large footprint, etc., and achieve filtration accuracy and dust removal efficiency. The effect of improving, wide application range and strong dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

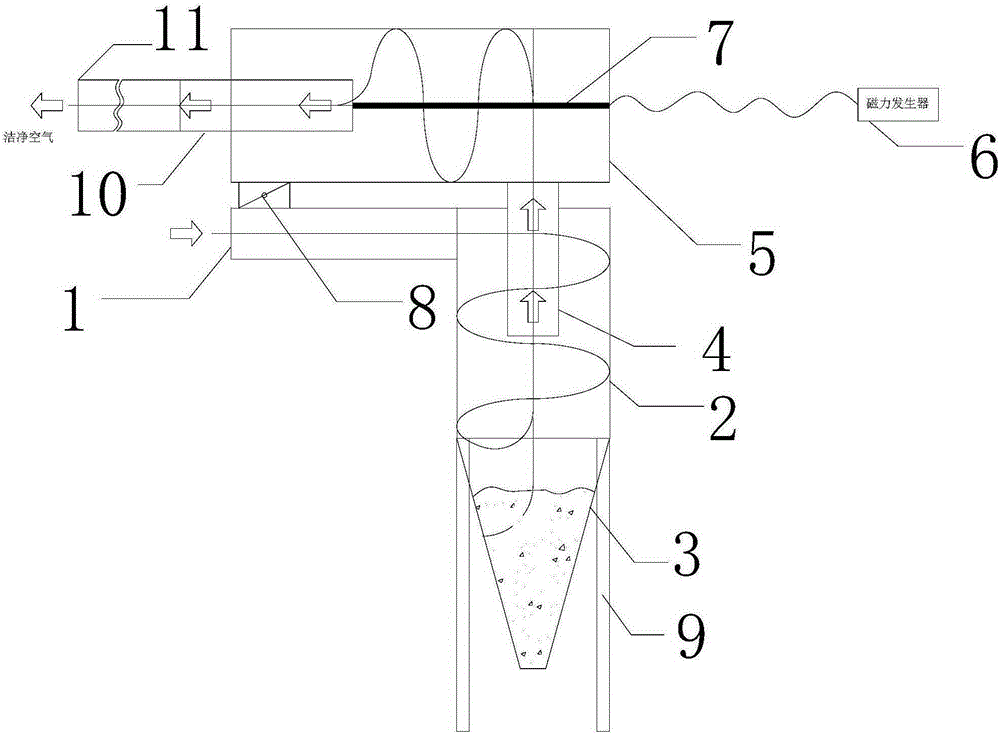

[0013] refer to figure 1 , a two-stage cyclone magnetic dust collector of the present invention, comprising an air intake pipe 1, a vertical cyclone cylinder 2, an ash hopper 3, an air pipe 4, a cyclone body 5, a magnetic force generator 6, a magnetic force line 7, a one-way ash valve 8, Leg 9, exhaust pipe 10, fan connection 11, the air intake pipe 1 is a cylindrical hollow pipe, the air intake pipe 1 is horizontally arranged, the vertical cyclone 2 is located on the right side of the air intake pipe 1, and the vertical cyclone The top of the left side wall of the vertical cyclone 2 is connected to the rightmost end of the air intake pipe 1, the shape of the vertical cyclone 2 is cylindrical, the vertical cyclone 2 is vertically arranged, and the bottom edge of the vertical cyclone 2 Several legs 9 are provided, the bottom of the vertical cyclone 2 is connected with an ash hopper 3, the shape of the ash hopper 3 is conical with the bottom shrinking, and the top of the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com