Welding method for reducing body deformation of armored car

A processing method and technology for armored vehicles, which are applied in welding equipment, metal processing, metal processing equipment, etc., can solve the problems of welding deformation of armored vehicle bodies that are not mentioned, and achieve the effect of improving assembly efficiency and ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

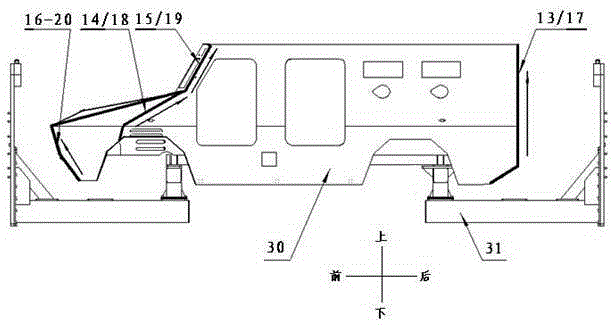

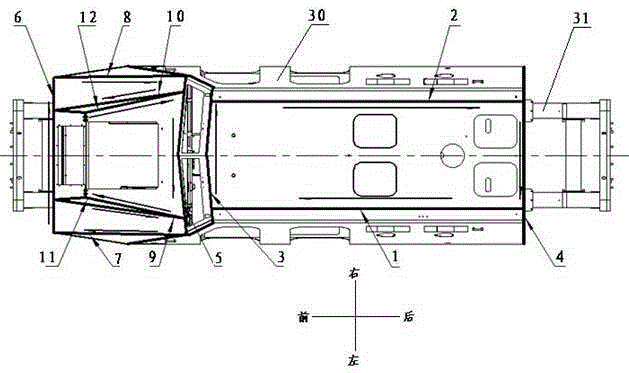

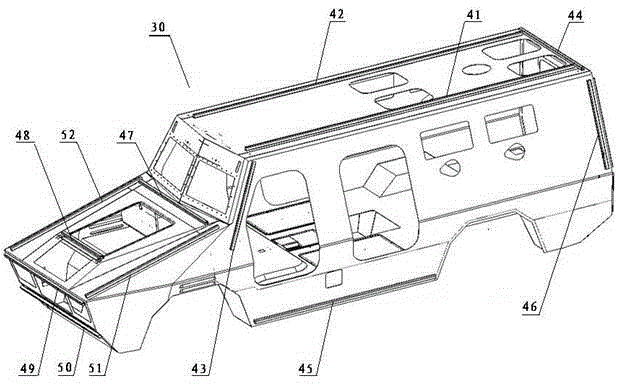

[0036] Embodiment one: see figure 1 , figure 2 , image 3 with Figure 4 , the welding processing method for reducing the deformation of the armored car body is characterized in that it comprises the following steps:

[0037] The first step is to arrange process reinforcing ribs on the armored vehicle body: the armored vehicle body 30 is made of imported Swedish steel plate DOMEXProtect500 steel plate or steel plate code-named 685 (ie 30MnCrNiMo steel plate); The frame structure is formed by spot welding reinforcement ribs on the car body to reduce welding deformation;

[0038] The second step is to install the armored vehicle body; install the armored vehicle body 30 with the frame structure formed by spot welding reinforcement ribs on the welding robot workstation-positioner 31, and the armored vehicle body can rotate 360°; in order to adjust the seam to achieve The best welding position is convenient for welding the body of the armored vehicle;

[0039] The third st...

Embodiment 2

[0056] Embodiment two: see figure 1 , figure 2 , image 3 with Figure 4 , the body of the armored vehicle is made of imported Swedish steel plate DOMEXProtect500 steel plate, the overall heat treatment method is adopted to remove the welding stress of the armored vehicle body, and it is carried out in a trolley-type tempering resistance furnace (RT-800×350×200-7) and heated to 150-180°C, heat preservation for 20±2h, air cooling. All the other are the same as the first embodiment.

Embodiment 3

[0057] Embodiment three: see figure 1 , figure 2 , image 3 with Figure 4 , the armored vehicle body is made of 685 steel plate (30MnCrNiMo), the overall heat treatment method is adopted to remove the welding stress of the armored vehicle body, heated to 180-220°C in a trolley-type tempering resistance furnace, kept for 20±2h, and air-cooled. All the other are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com