Dual-stirring rubber crusher

A glue breaker and dual technology, applied in recycling technology, grain processing, plastic recycling, etc., can solve the problems of low slicing efficiency, uneven crushing fineness, etc., to achieve easy rubber mixing, good breaking effect, and improve plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

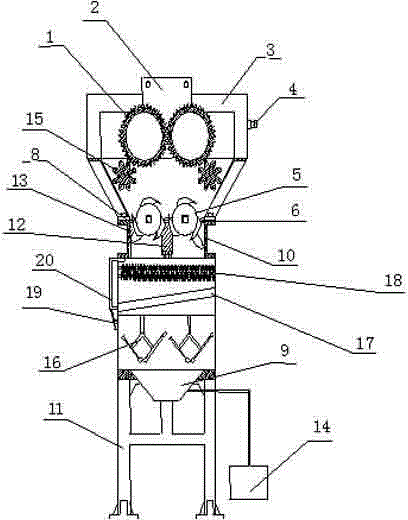

[0020] Combine below figure 1 The present invention is further described.

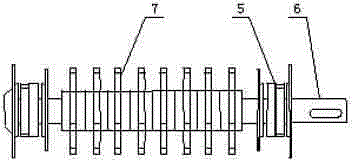

[0021] A double stirring rubber breaker, including a frame 11, a rubber breaking chamber 10, a double stirring chamber and a discharge hopper 9, characterized in that the frame 11 is arranged at the bottom, and the roller frame 3 is arranged above the frame 11 One side of the drum frame 3 is provided with a roller distance adjusting device 4 for adjusting the distance between the rollers 1; the inside of the rubber breaking chamber 10 is provided with a roller device, a rubber cutting knife group, and a power mechanism, and the roller device is arranged in the rubber breaking chamber The top of 10 includes two rollers 1 that cooperate with each other. There are evenly distributed grooves on the roller 1 along the axis of the roller 1. The rubber scraper 15 is set on both sides of the roller near the inner wall of the mixing chamber; the rubber cutter The group is set in the middle and lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com