Stereoscopic model forming equipment and forming method using same

A technology of forming equipment and three-dimensional model, which is applied in the field of three-dimensional model forming equipment and its forming, can solve problems such as affecting the forming accuracy, increasing the processing procedure, affecting the surface flatness of the three-dimensional model, etc., and achieves the effect of less disturbance and less dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

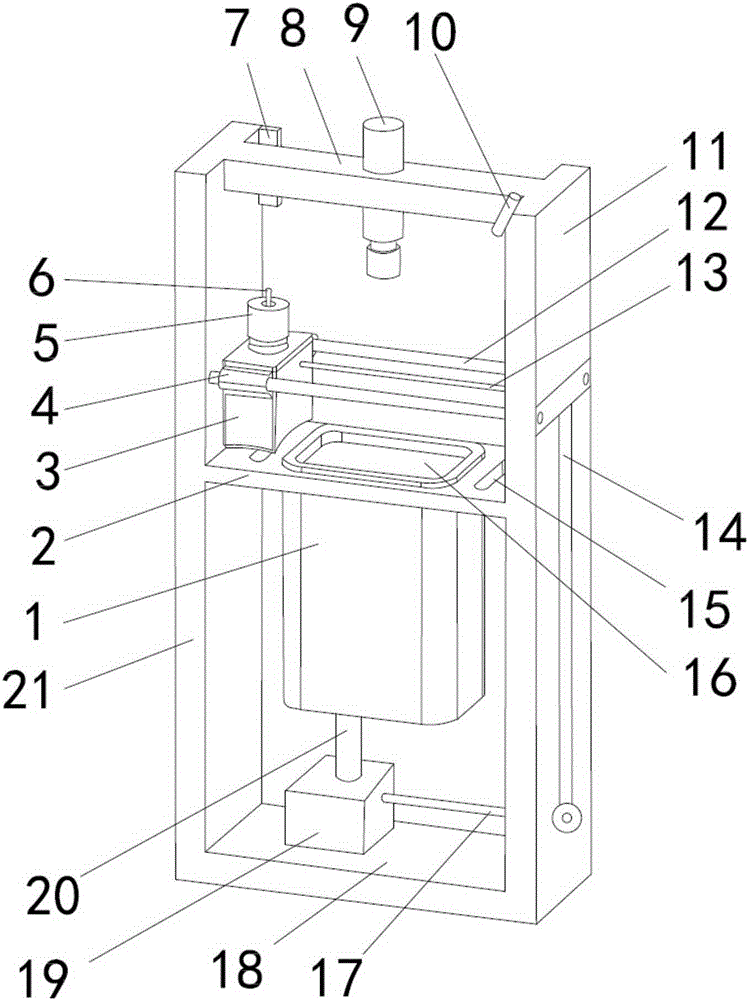

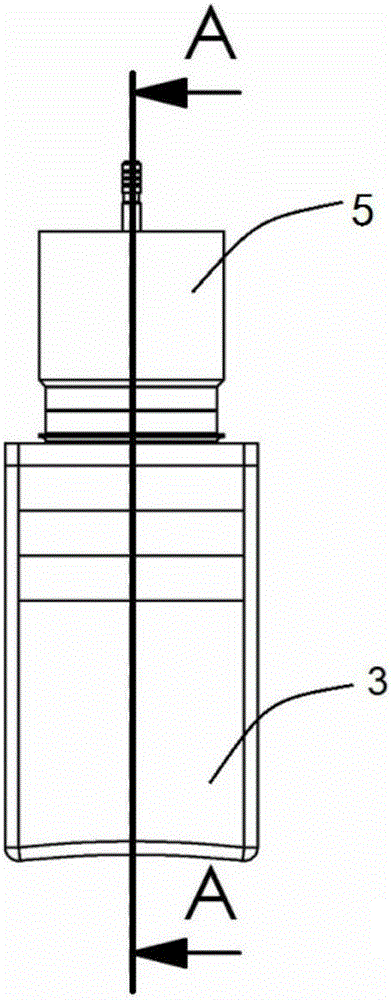

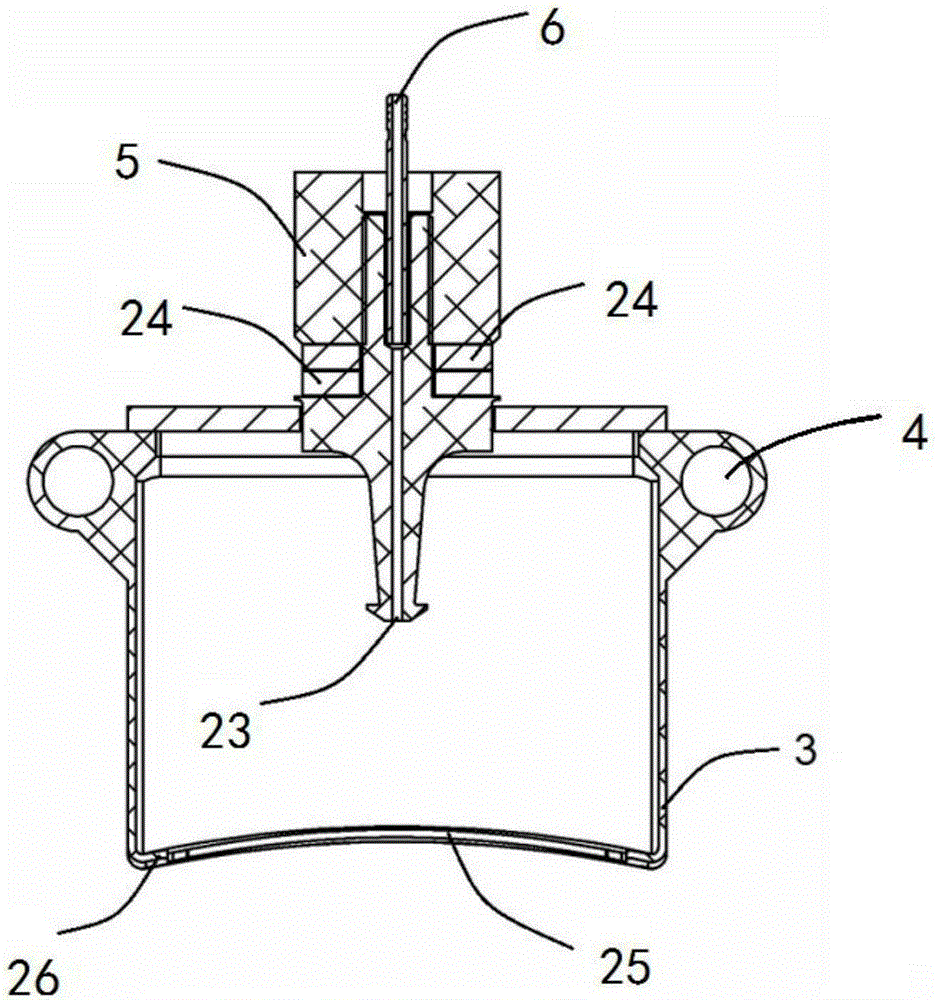

[0033] Such as figure 1 with 4As shown, a kind of three-dimensional model molding equipment provided by the present invention is specifically described. The molding equipment includes a control device and a frame 21 of a U-shaped structure, and a beam 8 is arranged between two side plates 11 of the U-shaped structure. The lower part of the beam 8 is provided with a workbench 2 in the middle of the frame 21, and the workbench 2 is embedded with a photocuring liquid container 1 with a cylindrical structure and an upward opening. The elevating rod 20 is connected to the forming platform 16 which moves up and down, and a sealing ring (not shown in the figure) is arranged between the inner wall of the cylindrical structure and the forming platform 16, so that the photocuring liquid will not leak and will not affect the The up and down movement of the forming platform 16, the lifting rod 20 is connected with the driving device 19 arranged on the bottom plate 18, the top of the form...

Embodiment 2

[0035] The present invention also provides a molding method using a three-dimensional model molding equipment provided with atomization and liquid spreading devices, comprising the following steps:

[0036] Step 1) Slicing and layering the three-dimensional model according to the preset thickness through the computer to obtain several laminated shapes with two-dimensional shapes of the three-dimensional model;

[0037] Step 2) Move the molding platform 16 at the bottom of the light-curing liquid container 1 to a projection height position, which is the height position at which the curing light projection device 9 realizes the focus of the curing light. The atomizing nozzle 23 in the device 5 atomizes the light-curing liquid into fine droplets, and the liquid spreading device moves horizontally above the forming platform 16 along the guide rail 12 so that the fine droplets are laid on the forming platform 16 Form the first layer of light curing liquid;

[0038] Step 3) Use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com