Light high-speed stacking machine

A stacker, high-speed technology, applied in the field of high-bay three-dimensional warehouse storage equipment, can solve the problems of difficulty in ensuring the synchronization of the movement of the whole machine, low positioning accuracy, low positioning accuracy, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

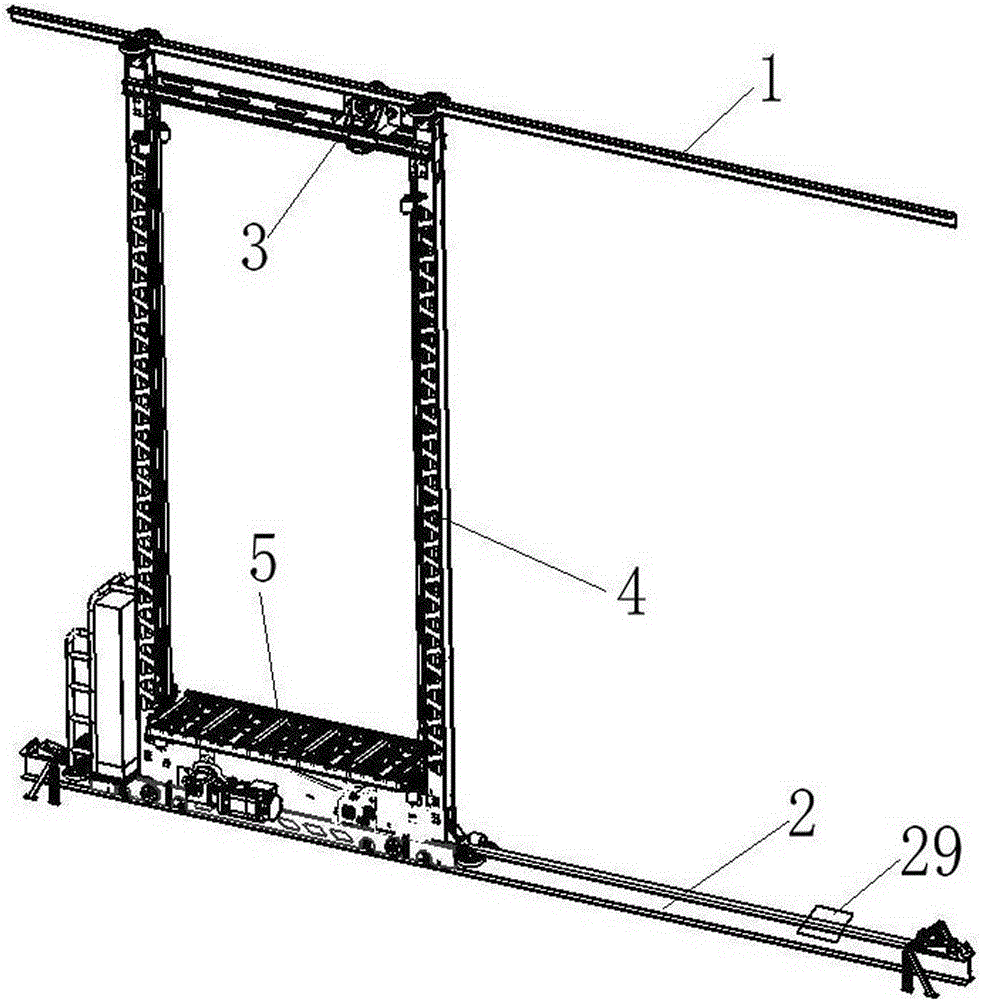

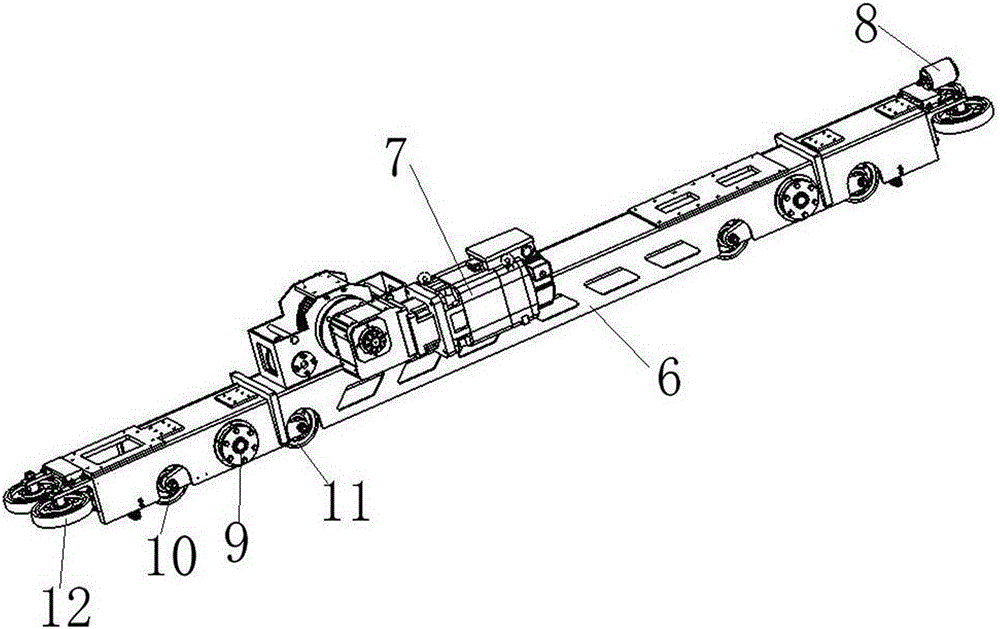

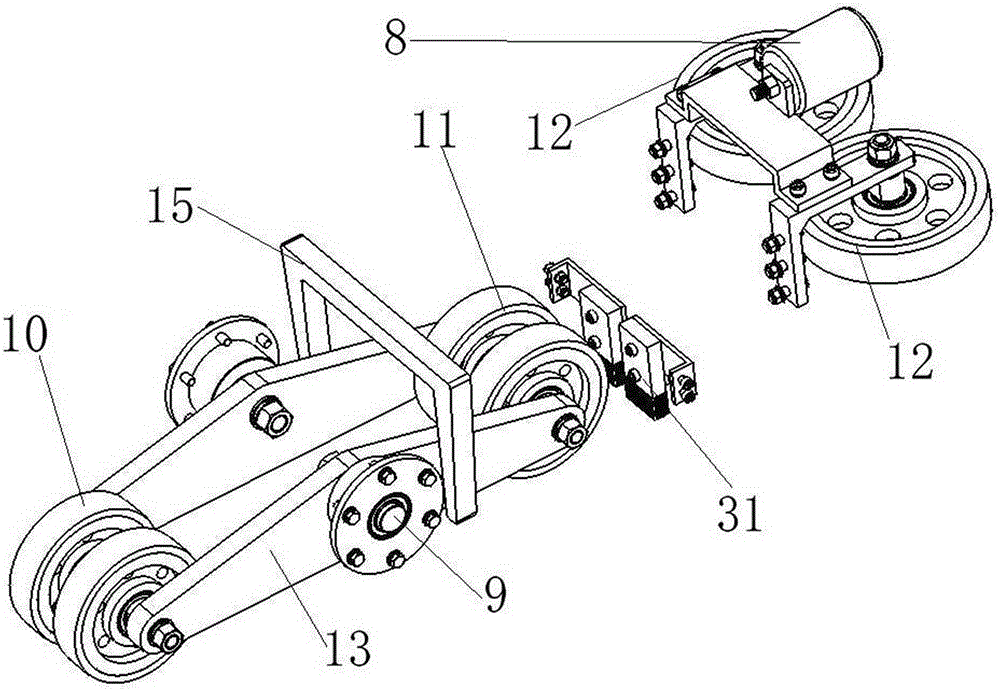

[0029] Attached below figure 1 To attach Figure 6 The present invention will be further described.

[0030] as attached figure 1 As shown, a light-duty high-speed stacker includes: an upper traveling mechanism 3, which is slidably installed on the sky rail 1, and is driven by a servo motor to move along the sky rail 1; a lower traveling mechanism, which is slidably installed on the ground rail 2 and driven by the servo motor I7 to move along the ground rail 2; two parallel vertical columns 4 are welded by section steel to form a frame structure, and the two columns 4 are respectively connected with the upper traveling mechanism 3 and the lower traveling mechanism. Connect and fix to form a rectangular structure; the lifting platform 21 is slidably installed on the inner side of the column 4 along the vertical direction; the cargo platform 5 arranged horizontally, its two ends are respectively fixed on the lifting platform 21 on both sides; and the driving device of the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com