Method for improving transmission performance of flow battery and flow battery

A technology of flow battery and transmission performance, applied in fuel cells, fuel cell additives, regenerative fuel cells, etc., can solve the problems of low battery power density, increase the ion diffusion coefficient in the electrolyte of flow battery, etc. Reaction kinetics, good biocompatibility and degradability, the effect of increased conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Prepare ethylene glycol-based deep eutectic solvent solution, mix choline chloride and ethylene glycol according to a molar ratio of 1:2, continue stirring at a heating temperature of 50°C until a colorless and transparent deep eutectic solvent is formed, and Cooling was performed at room temperature 25°C.

[0043] The positive electrode active material, the negative electrode active material FeCl 2 and VCl 3 Add 0.1mol / L concentration into 60mL deep eutectic solvent respectively to prepare electrolyte based on deep eutectic solvent.

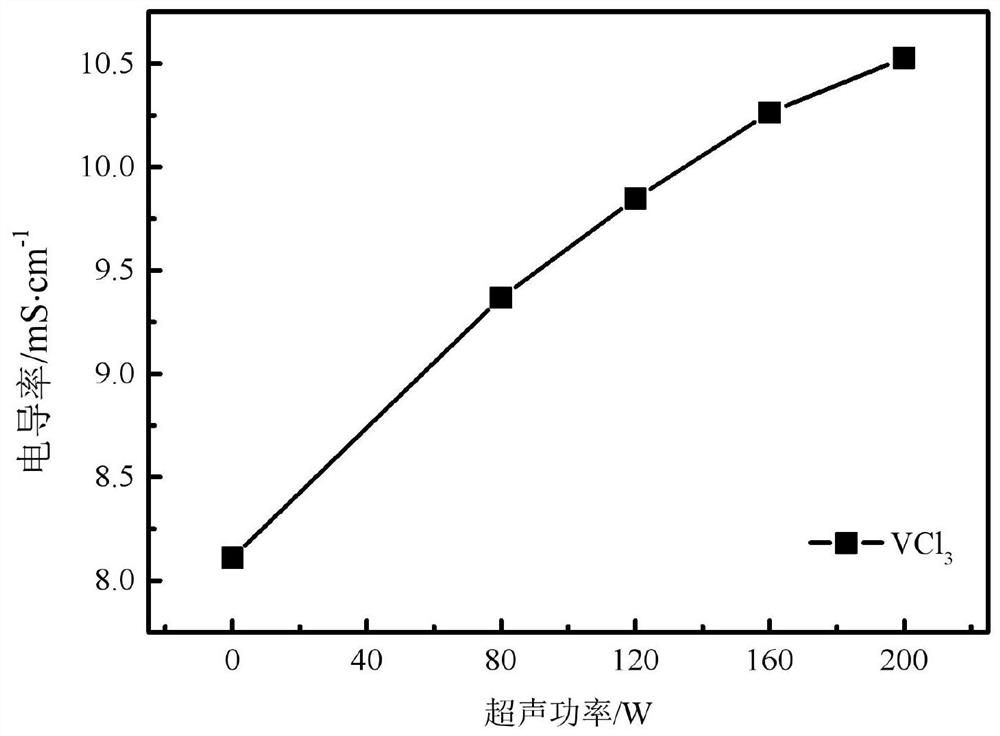

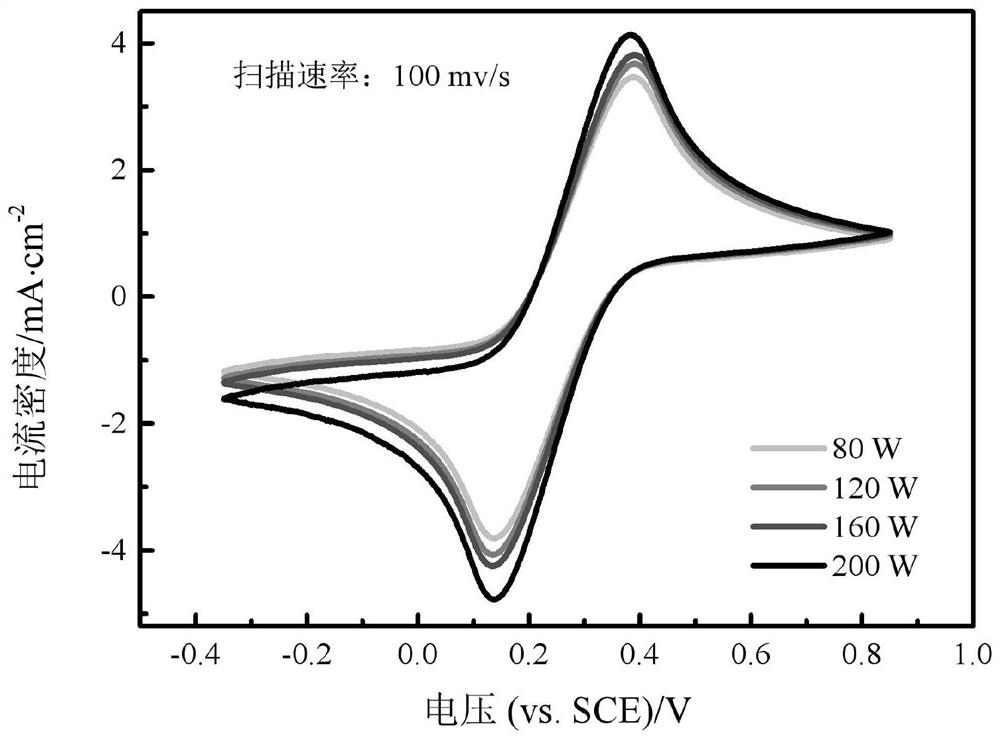

[0044] The prepared positive electrode electrolyte is placed in the ultrasonic generator 5, and the ultrasonic power ranges from 80W to 200W.

[0045] A conductivity meter was used to test the change of the conductivity of the cathode electrolyte under different ultrasonic powers. Test results such as figure 2 As shown, when no ultrasonic wave is added, that is, when the ultrasonic power is 0, the conductivity of the positive electro...

Embodiment 2

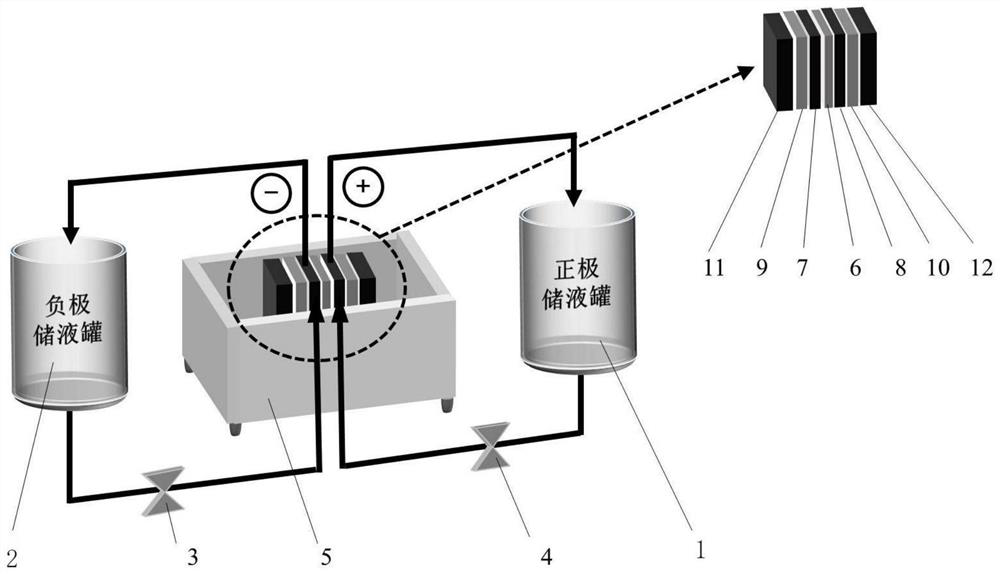

[0059] Prepare positive and negative electrolytes based on deep eutectic solvents, and use FeCl as the positive active material 2 , VCl is selected as the negative electrode active material 3 , the ion exchange membrane 6 uses Nafion212 diaphragm, and the electrode uses GFA series graphite felt electrodes to assemble the flow battery; the assembled flow battery is as follows figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com