Control system and method used for reaction gas compressor

A control system and compressor technology, applied in the field of control, can solve problems such as surge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

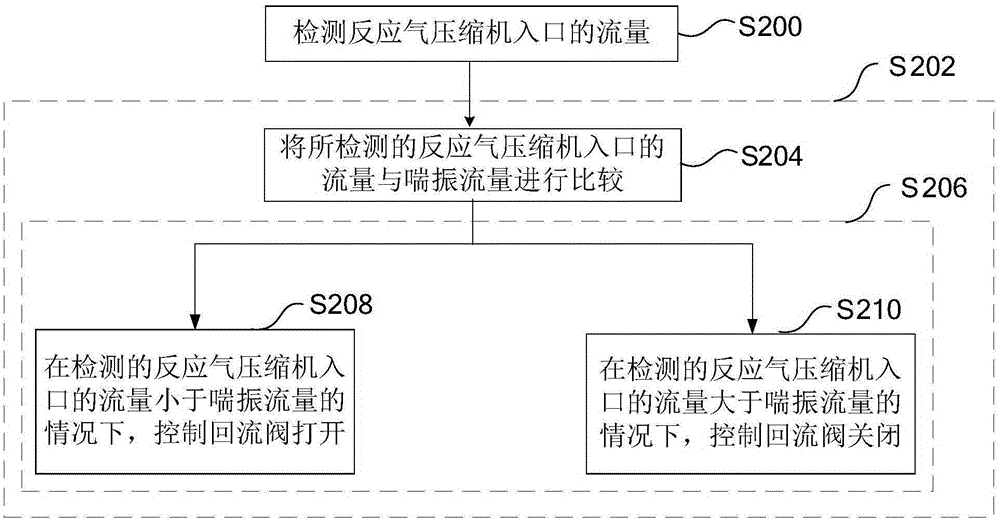

[0018] According to one embodiment of the present invention, the control device 20 controlling the return valve 30 of the reaction gas compressor according to the comparison result includes:

[0019] When the detected flow rate at the inlet of the reaction gas compressor is less than the surge flow rate, the control device 20 controls the return valve 30 to open;

[0020] When the detected flow rate at the inlet of the reactant gas compressor is greater than the surge flow rate, the control device 20 controls the return valve 30 to close.

[0021] Therefore, when the detected flow rate is less than the surge flow rate, the control device 20 can control the return valve 30 to open, thereby allowing the gas at the outlet of the reaction gas compressor to flow back into the reaction gas The inlet of the compressor ensures that the flow rate at the inlet of the reaction gas compressor is always greater than the surge flow rate, thereby preventing the occurrence of surge. And when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com