Method and system for controlling decelerating and deflating process of automobile supercharged gasoline engine and automobile

A technology of process control and gasoline engine, applied in electrical control, engine control, mechanical equipment, etc., can solve the problems of high cost, complicated air leakage control system, and unable to solve the root cause of air leakage noise, so as to solve the problem of surge and avoid air leakage Effects of Noise Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

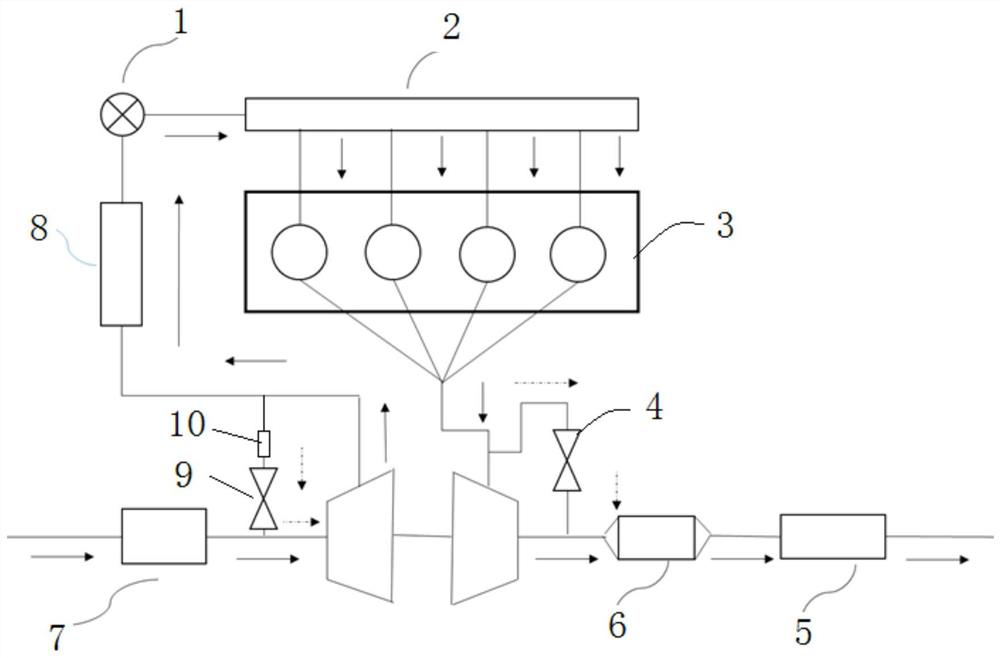

[0037] like figure 1 As shown, the system structure of a conventional turbocharged engine includes a throttle body 1, an intake manifold 2, an engine body 3, a wastegate valve 4, a muffler 5, a three-way catalytic converter 6, an air filter 7, and an intercooler 8 , ECRV bypass valve 9 and high frequency resonant cavity 10.

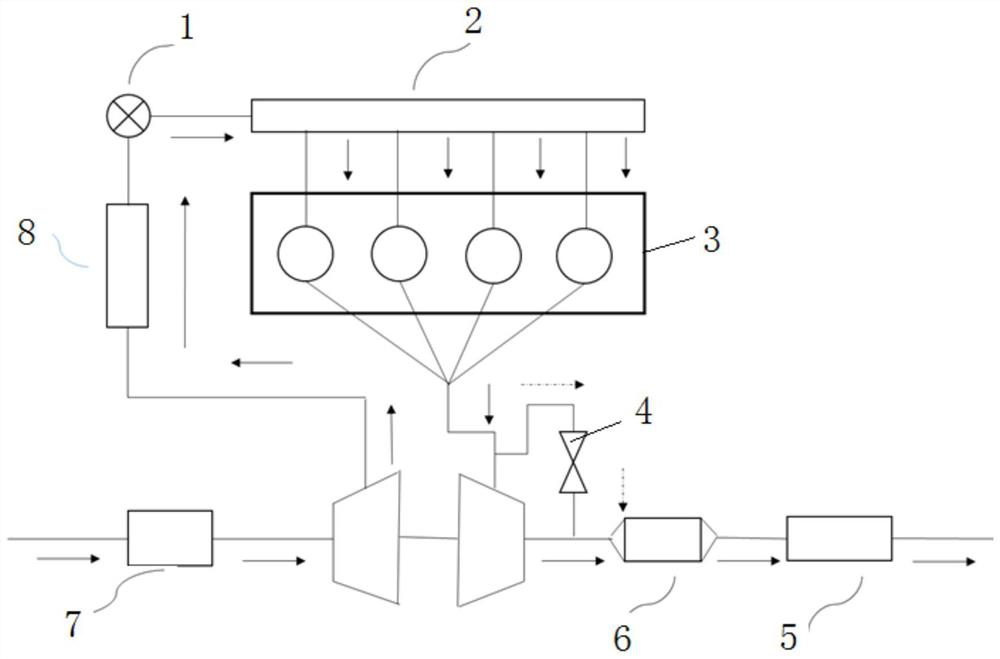

[0038] like figure 2As shown, the engine system structure after canceling the ECRV bypass valve includes throttle body 1, intake manifold 2, engine body 3, wastegate valve 4, muffler 5, three-way catalytic converter 6, air filter 7 and Intercooler8.

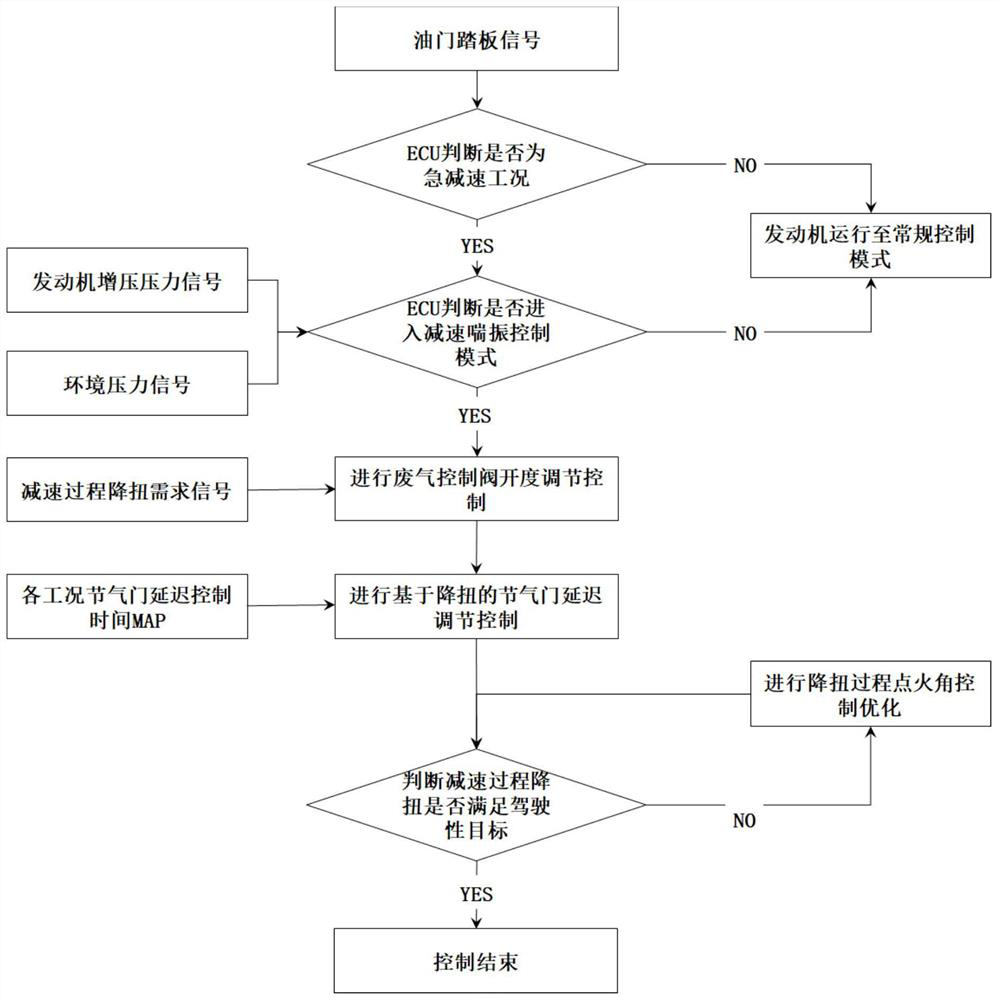

[0039] like image 3 As shown, in the present embodiment, a method for controlling the process of decelerating and blowing gas of an automobile supercharged gasoline engine comprises the following steps:

[0040] Step 1. Determine the current working condition:

[0041] The engine control unit obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com