A hydraulic pipeline fluid pulsation damping device based on piezoelectric shunt damping technology

A hydraulic pipeline and pulsation attenuation technology, which is applied to pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as high driving voltage or magnetic field strength, overheating of actuators, complex active control systems, etc., to achieve Improve the pulsation attenuation effect and maintain the effect of dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

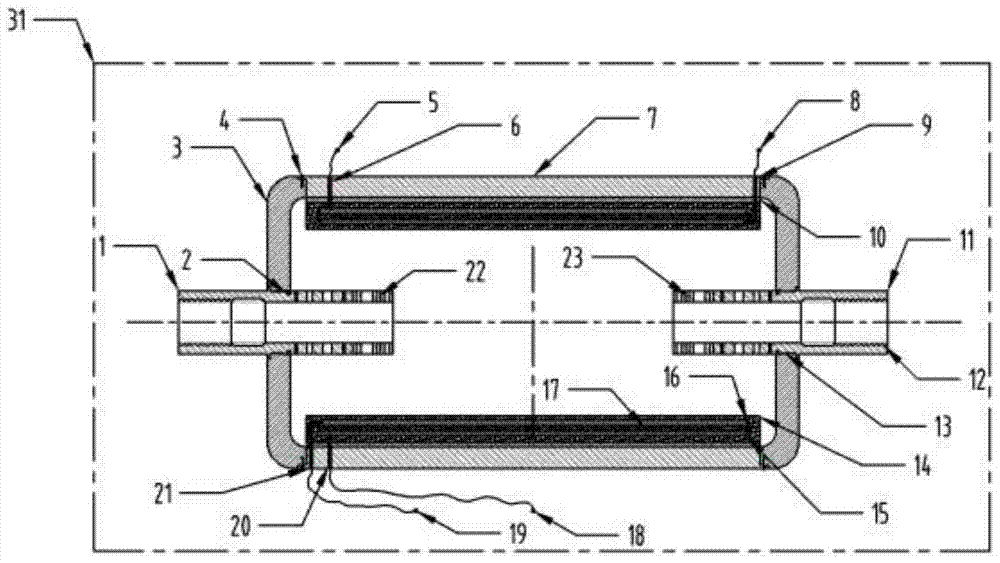

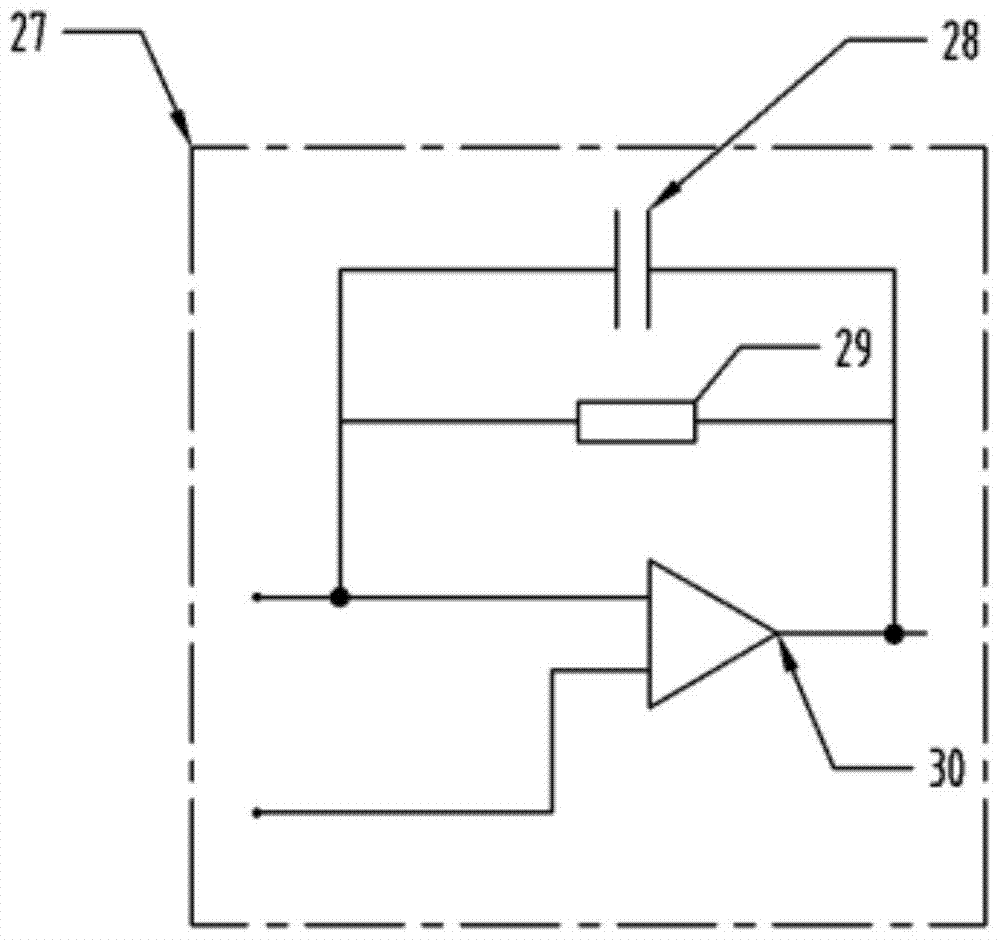

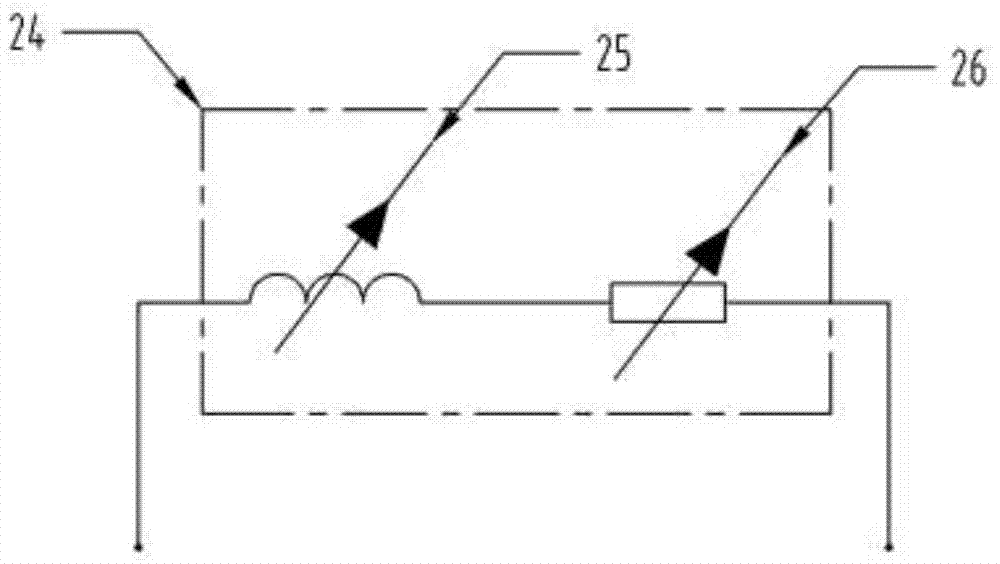

[0019] The present invention is based on the hydraulic pipeline fluid pulsation attenuation device based on piezoelectric shunt damping technology, such as figure 1 , 2 , 3, the inlet pipe 1 and the outlet pipe 11 extend into the cavity of the attenuator, and are connected to the end cover 3 through the threaded part 13 . The left and right end caps 3 of the attenuator and the upper and lower end caps 7 are connected by slotted cylindrical head screws 4; in order to increase the output voltage of the charge amplifier circuit 27, the PVDF piezoelectric film 17 is connected in parallel, and on both sides of the PVDF piezoelectric film Bonding aluminum electrodes (15 and 16) to make a PVDF piezoelectric film sensor; wrapping the PVDF piezoelectric film 17 and the aluminum electrodes with epoxy resin 14, and then bonding them on by 502 adhesive 10, On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com