Piezoelectric-shunt-damping-technology-based active and passive integrated control method for hydraulic pipeline fluid pulsation

A technology of hydraulic pipeline and control method, applied in the direction of fluid pressure actuating device, fluid pressure actuating system component, pipe element, etc. The third harmonic and higher harmonics are powerless and other problems, so as to achieve the effect of improving the pulsation attenuation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

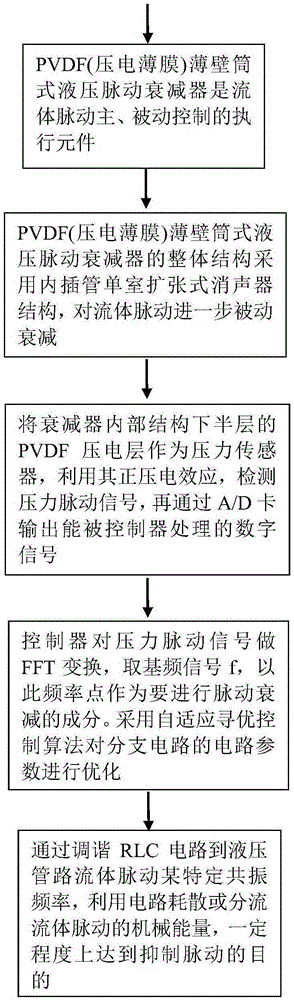

[0045] Below in conjunction with accompanying drawing, the structure of the present invention is described in further detail.

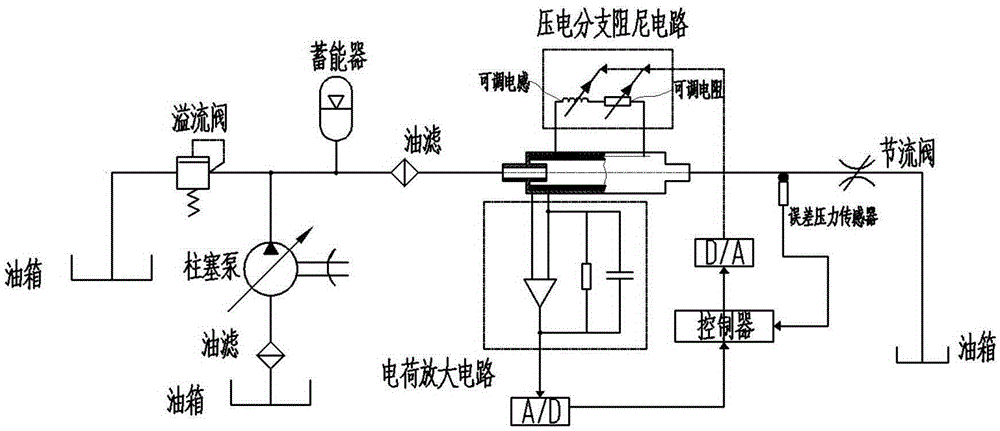

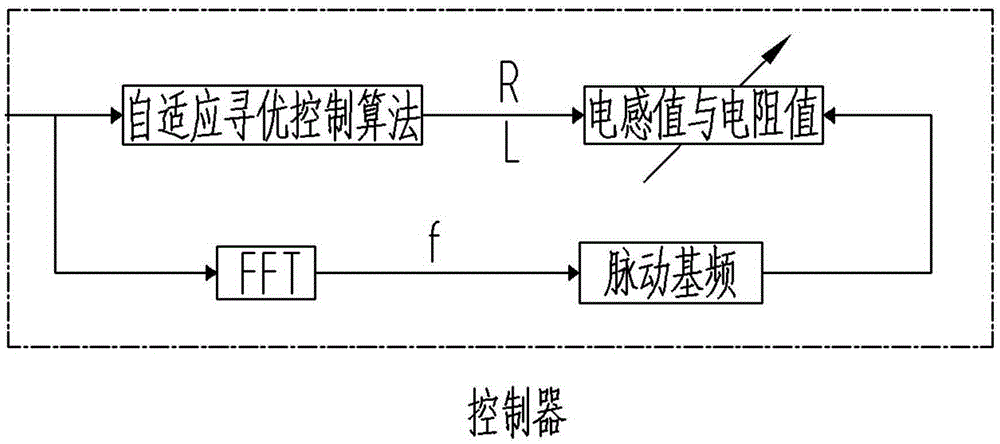

[0046] According to the present invention, a hydraulic pipeline fluid pulsation active and passive integrated control method based on piezoelectric shunt damping technology, the control object is the basic hydraulic pipeline system, and its typical mechanism is as follows: figure 2 As shown, it consists of oil tank, oil filter, motor, plunger pump, accumulator, overflow valve, hydraulic pipeline and adjustable throttle valve. The specific connection relationship is as follows: the motor drives the plunger pump to absorb oil from the oil tank to generate a certain flow of high-pressure fluid. If the oil pressure reaches the set pressure of the overflow valve, it will directly overflow back to the oil tank; if the oil pressure does not reach the overflow When the pressure is set by the valve, the oil enters the hydraulic pipeline, and an adjustable thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com