Refraction-based solar homogeneous tube reactor or dryer and its design method

A tubular reactor, dryer technology, applied in the direction of solar collectors, solar collectors, solar thermal energy using working fluid, etc. To reduce the energy loss and improve the efficiency of light and heat utilization, the problem of limited light receiving angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

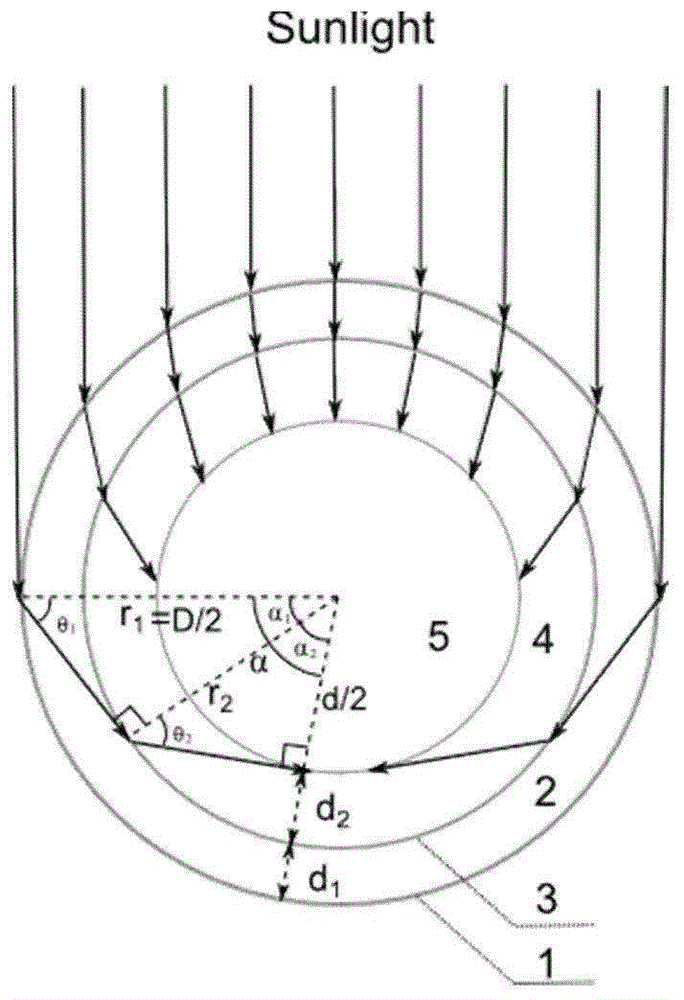

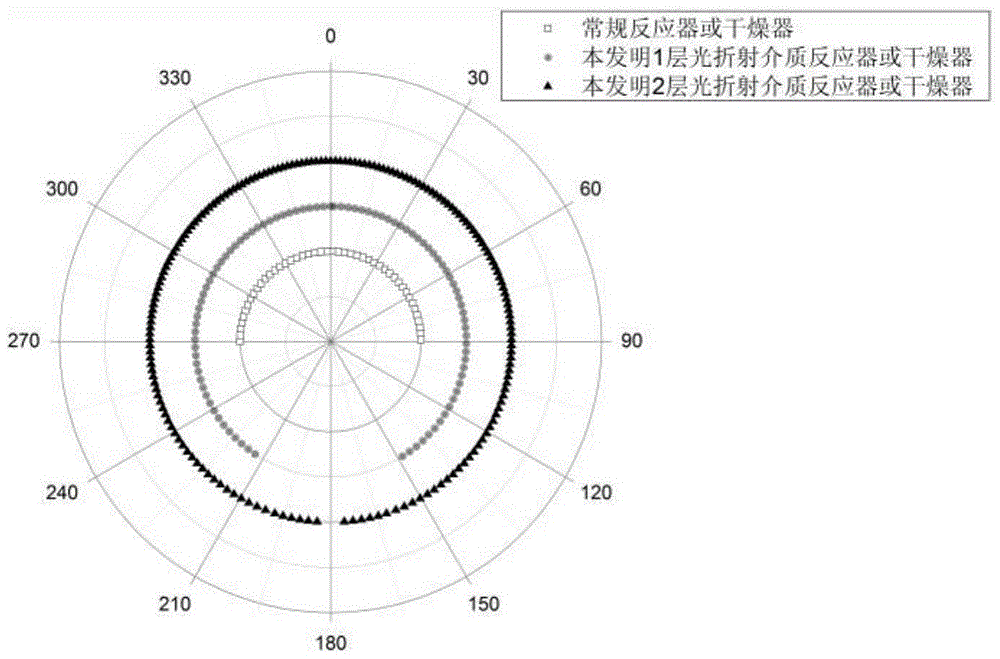

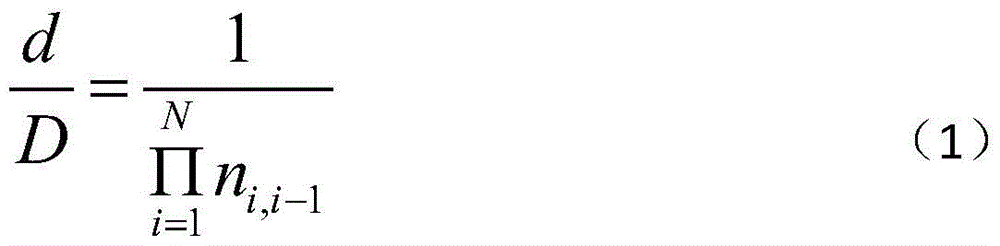

[0038] Utilize reactor or drier design and optimization method of the present invention, design has the solar energy reactor of 1 layer (N=1) light refraction medium or drier, assume that reactor or drier external diameter (D) is 4cm, the outer cover There is an anti-reflective coating to reduce the reflection loss of light. The inner diameter (d) of the dryer or reactor is 2.12cm. Under the condition of optimal light distribution, according to the formula (1):

[0039]

[0040] The thickness d of the light-refractive medium can be obtained from formula (2) 1 :

[0041]

[0042] The maximum total deflection angle α(°) of light can be obtained from formula (3):

[0043]

[0044] According to the refractive index value, the light refraction medium of this layer can be selected as extra-heavy flint glass material (refractive index 1.89), and the thickness is 0.94cm, so as to determine the geometric size and material of the reactor or dryer, and complete the solar reactor ...

Embodiment 2

[0046] Utilize the present invention to design solar reactor or drier with 2 layers (N=2) light refraction medium, assuming reactor or drier external diameter (D) is 4cm, is covered with anti-reflection film outside, reduces the reflection loss of light, The inner diameter (d) of the dryer or reactor is 2.12cm. Under the condition of optimal light distribution, according to the formula (1), it can be known that

[0047]

[0048] From this, the refractive index of the two layers of photorefractive medium can be obtained as follows:

[0049] no 2,1 n 1,0 =1.89

[0050] According to the refractive index of the material, and the refractive index of the inward second layer of photorefractive medium is higher than that of the inward first layer of photorefractive medium, n can be selected 1,0 = 1.5, n 2,1 = 1.26, so n 2,0 =1.89, an anti-reflection coating is designed between the two layers of light-refractive media to reduce the reflection loss of light. Therefore, it is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com