Trapezoidal thread visual detection method

A visual inspection and trapezoidal thread technology, applied in the field of trapezoidal thread visual inspection, can solve the problems of slow measurement speed, unfavorable automatic inspection speed of assembly line, low measurement accuracy, etc., and achieve the effect of avoiding system errors, strong reliability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

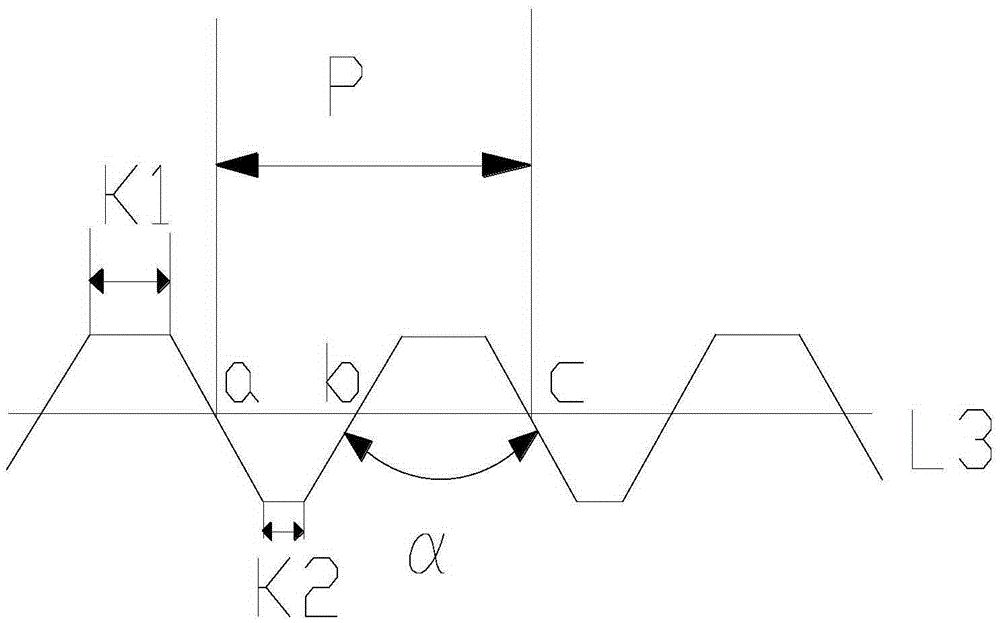

[0053] Trapezoidal thread is also known as ordinary thread, and its thread shape is as follows: figure 1 As shown, the main parameters of the trapezoidal thread are: thread major diameter d, thread minor diameter d1, thread diameter d2, pitch p and tooth angle α. The trapezoidal thread visual inspection method provided in this embodiment is based on the detection of the above parameters. If the requirements are met, it proves that the trapezoidal thread is a qualified workpiece, otherwise it is unqualified.

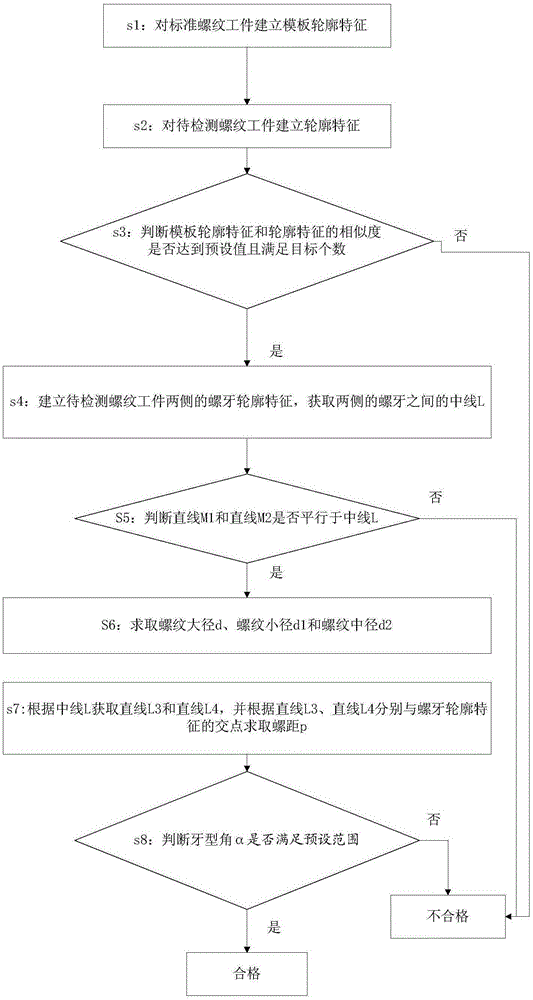

[0054] see figure 2 , this embodiment includes the following steps:

[0055] Step s1: Establish template contour features for standard threaded workpieces;

[0056] Step s2: Establish contour features of the threaded workpiece to be detected;

[0057] Step s3: Determine whether the similarity between the profile features of the template of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com