Titanium alloy fixing device with circular slide rail and four-side ball bearings in same plane

A fixed device, titanium alloy technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of long time-consuming, operator injury, inconvenient operation, etc., to ensure personal safety, shorten operation time, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

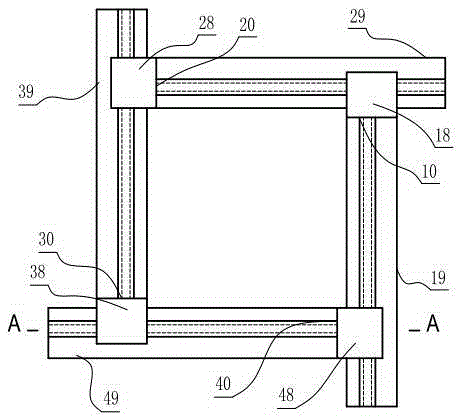

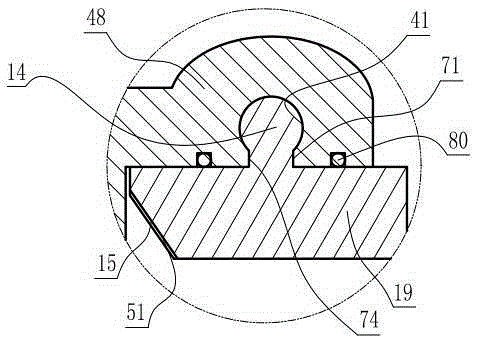

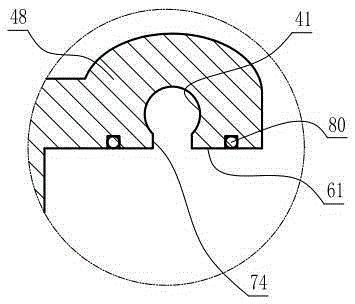

[0038] figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 9 , Figure 10 , Figure 11 and Figure 12 Middle: Titanium alloy fixing device with four side sliding balls on the same plane of the round rail slideway, including four first fixing plates 10, second fixing plates 20, third fixing plates 30 and fourth fixing plates 40 with the same structural size, each fixed The plate is composed of a fixed part and a slide part, the first fixed plate 10 is composed of a first fixed part 19 and a first slide part 18, and the second fixed plate 20 is composed of a second fixed part 29 and a second slide part 28, The third fixed plate 30 is made up of the third fixed part 39 and the third slide part 38, and the fourth fixed plate 40 is made up of the fourth fixed part 49 and the fourth slide part 48; One end of the part and overlapped on the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com