A method for identifying wood quality

A wood and quality technology, applied in the field of wood processing, can solve the problems of rapid identification of wood quality without reports, and achieve the effects of low cost and simple detection method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for identifying wood quality, said method comprising the steps of:

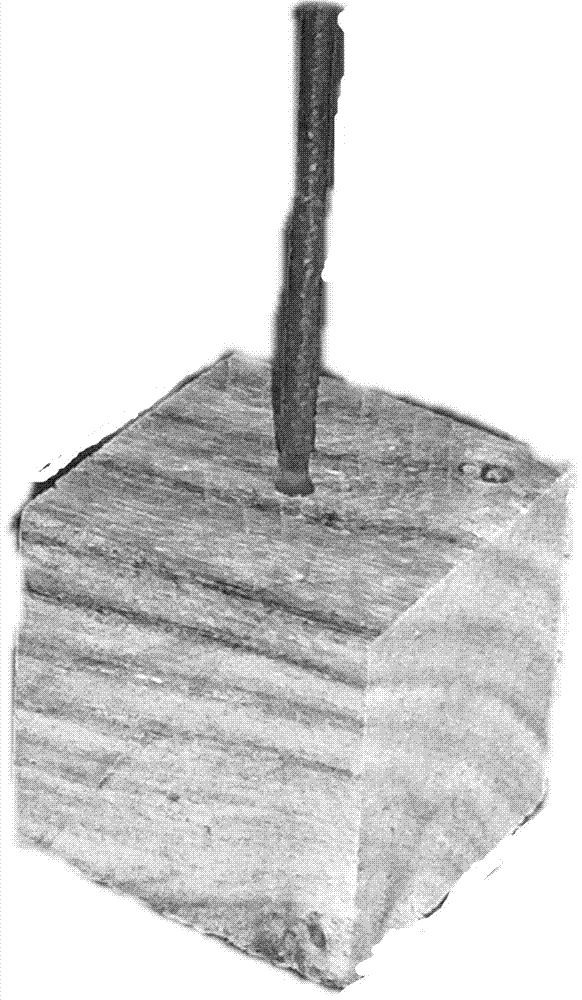

[0034] 1) Standard sample production: take a wood sample of known type, polish the glaze on each face of the wood sample with sandpaper, the abrasive grain size of the sand paper is 1800, and obtain the wood standard sample;

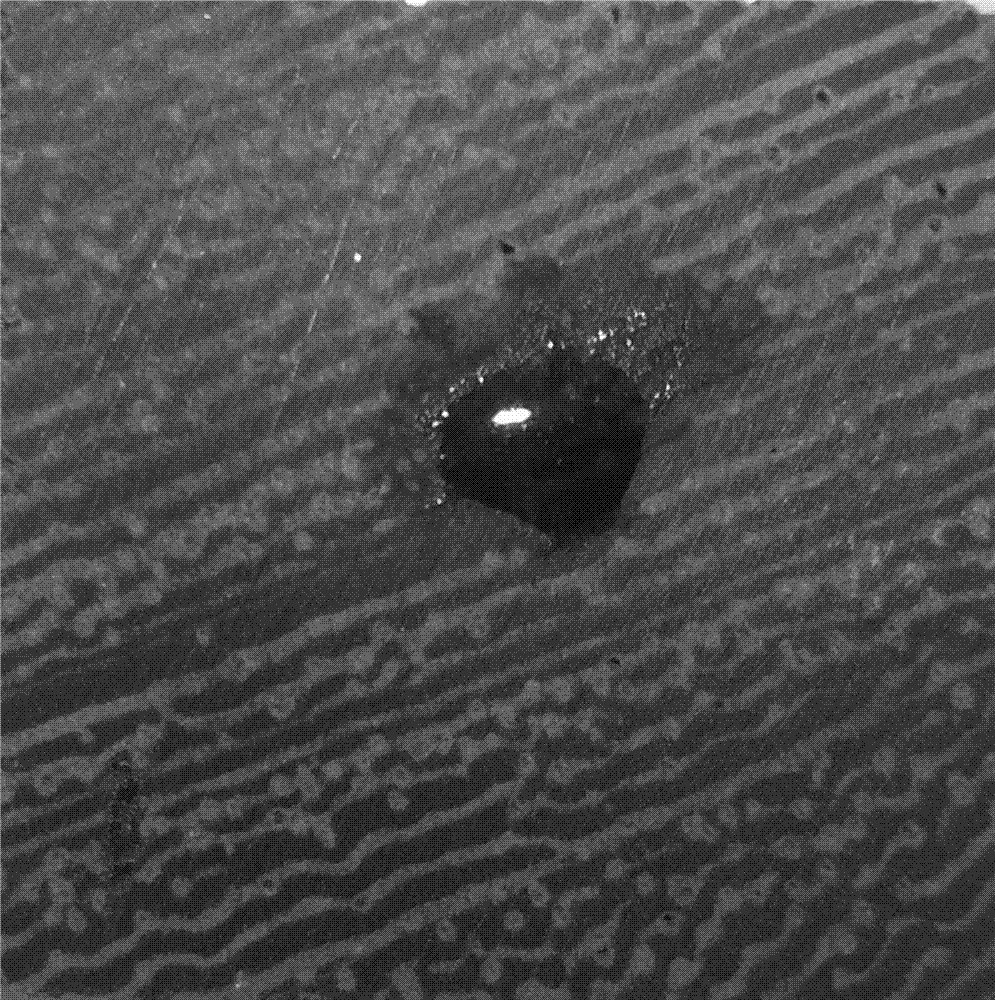

[0035] 2) Titration solution preparation: Stir the pigment and water evenly, and the volume ratio of the pigment and water in the titration solution is 1:500 to obtain a titration solution;

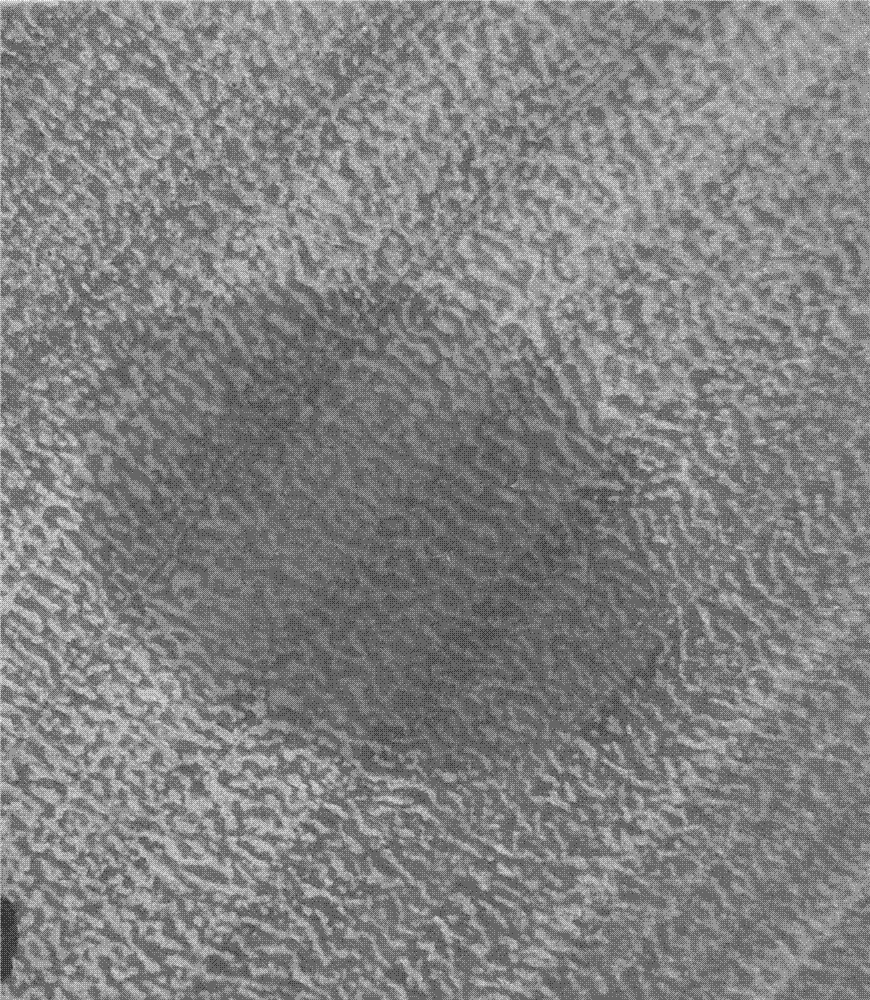

[0036] 3) titration of wood standard sample: determine titration point on the wood standard sample of described step 1), and titration point is positioned at the radial cut surface of wood, draws the titration solution of described step 2) with capillary, vertically stands capillary at titration point At the top, make the lower part of the capillary contact with the titration point surface, start titration and timing, record the titration amount per unit time, calculate the titratio...

Embodiment 2

[0043] A method for identifying wood quality, said method comprising the steps of:

[0044] 1) Standard sample production: take a wood sample of known type, polish the glaze on each face of the wood sample with sandpaper, the abrasive grain size of the sand paper is 2000, and obtain the wood standard sample;

[0045] 2) Titration solution preparation: Stir the pigment and water evenly, and the volume ratio of pigment and water in the titration solution is 0:500 to obtain a titration solution;

[0046] 3) titration of wood standard sample: determine titration point on the wood standard sample of described step 1), and titration point is positioned at the cross-section of wood, draws the titration solution of described step 2) with capillary, vertically stands capillary at titration point At the top, make the lower part of the capillary contact with the titration point surface, start titration and timing, record the titration amount per unit time, and calculate the titration rat...

Embodiment 3

[0062] Uniformity differences on the same side of the same wood:

[0063] Using the method of Example 1, titrate different parts on the same surface of the same wood, and compare the water absorption rate. If the difference in rate is not more than 10%, it can be considered that the surface is relatively uniform; otherwise, it means that the surface is uneven and the distribution of voids is uneven uniform.

[0064] According to the comparison of titration rates at four different points on the same surface of golden wood in Table 2, the difference between the maximum rate of 0.043cm / s and the minimum rate of 0.040cm / s is 6.9%<10%, indicating that the test surface of golden wood is relatively uniform. (Because the radial section rate value is large and easy to distinguish, the radial section is used.)

[0065] Table 2 Comparison of uniformity difference data on the same surface of the same wood

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com