Paper making process for precoating water transfer printing base paper

A papermaking process and water transfer printing technology, which is applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems of rough surface, inconsistent stripping time, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

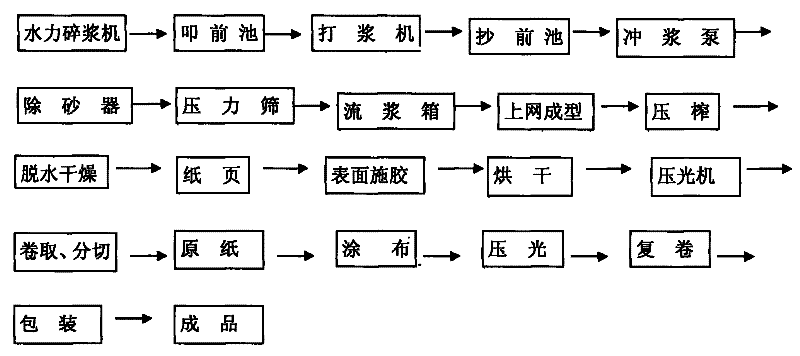

Method used

Image

Examples

Embodiment 1

[0032] Add 2800kg of clear water and 200kg of denatured oxidized starch to the glue pot, stir evenly, slowly heat up and boil, when the temperature rises to 98°C, keep it warm for 15 minutes, then cool down to 69°C, stir evenly, filter to obtain a surface sizing solution, and set aside .

[0033] Pulping is pulverized by a hydraulic pulper, with 2.6mm bleached kraft softwood long-fiber wood pulp and short-fiber wood pulp with a fiber length of 1.1mm bleached kraft softwood, and the weight ratio is long-fiber wood pulp: short Fiber wood pulp = 3:7, pulverized by a hydropulper, adding a charge enhancer with a concentration of 14% when pulping, and the amount per ton of paper is 10kg, transferred to the pre-knock pool, passed through a double-disc mill beater, beating, current 380A, The beating concentration is 4.0%, the beating degree is 23°SR, and the slurry is prepared, and then the wet strength agent with a concentration of 1.0% is added, and the amount of paper per ton is 10...

Embodiment 2

[0039]Add 2900kg of clear water and 190kg of denatured oxidized starch to the glue pot, stir evenly, slowly heat up and boil, when the temperature rises to 100°C, keep it warm for 16 minutes, then cool down to 70°C to prepare a surface sizing solution for future use; pulping, Pulverized by a hydropulper, the bleached kraft softwood long-fiber wood pulp of 2.7 mm and the short-fiber wood pulp of 1.2 mm bleached kraft soft-leaf wood pulp with a weight ratio of long-fiber wood pulp: short-fiber wood pulp =2:8, pulverized by a hydraulic pulper, adding a charge enhancer with a concentration of 15% when pulping, and the amount of paper per ton is 11kg, transferred to the pre-knock pool, and beaten by a double-disc mill beater with a current of 390A and a beating concentration 3.9%, beating degree 24°SR, after the pulp is obtained, add a wet strength agent with a concentration of 0.95%, the amount per ton of paper is 110kg, stir evenly, transfer to the mixing tank, prepare the pulp, p...

Embodiment 3

[0044] Add 2800kg of clear water and 210kg of denatured oxidized starch to the glue pot, stir evenly, slowly heat up and boil, when the temperature rises to 105°C, keep it warm for 18 minutes, then cool down to 75°C, stir evenly, filter to obtain a surface sizing solution, spare.

[0045] Pulping is pulverized by a hydraulic pulper, with 2.6mm bleached kraft softwood long-fiber wood pulp and short-fiber wood pulp with a fiber length of 1.0mm bleached kraft softwood, and the weight ratio is long-fiber wood pulp: short Fiber wood pulp = 2:8, pulverized by a hydropulper, adding a charge enhancer with a concentration of 15% when pulping, and the amount per ton of paper is 12kg, transferred to the pre-knock pool, passed through a double-disc mill beater, beating, current 400A, The beating concentration is 4.3%, the beating degree is 25°SR, and the pulp is prepared, and then the wet strength agent with a concentration of 1.1% is added, and the amount of paper per ton is 100kg. Stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com