Marine structure model segmented pressurizing type constant temperature salt fog accelerated erosion test system

A segmented pressurization and marine structure technology, which is applied in the direction of analyzing materials, weather resistance/light resistance/corrosion resistance, measuring devices, etc., can solve problems such as inaccurate basic models, deviation, and difficulty in controlling ion concentration, and achieve shortened forecast Processing time, flexibility, and versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

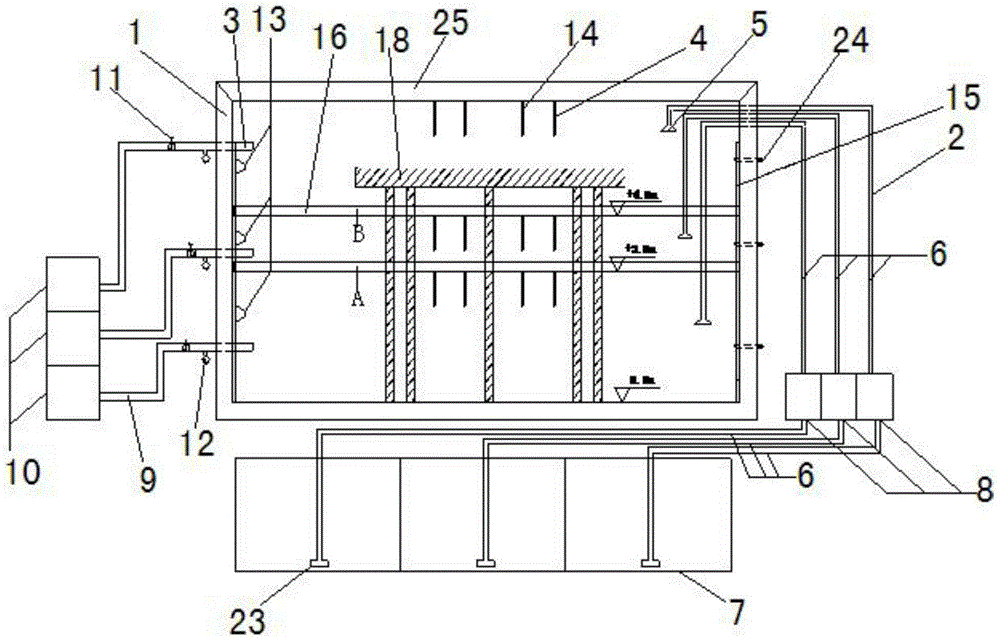

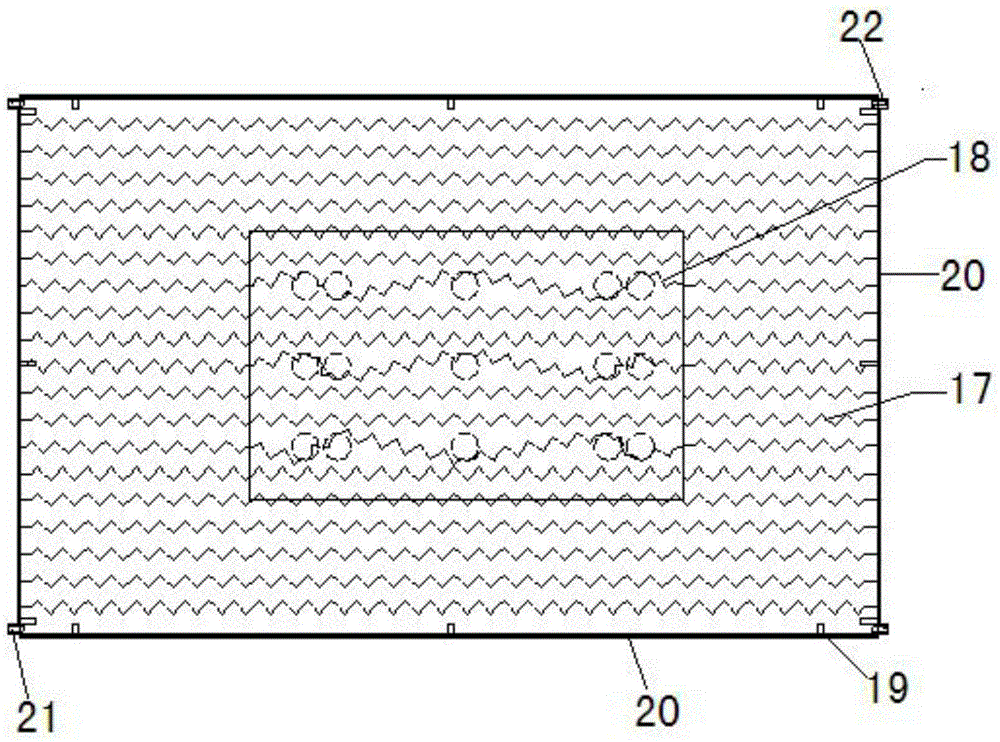

[0037] Such as Figure 1~Figure 2As shown, the subsection pressurized constant temperature salt spray accelerated erosion test system for the marine structure model is characterized in that it includes: a subsection sealed pressurized test chamber 1, and each section of the subsection sealed pressurized test chamber 1 is provided with There are salt mist spray module 2, booster module 3 and constant temperature module 4; on the inner side wall of the section sealed pressure test chamber 1, slide rails 15 are vertically arranged symmetrically, and the slide rails 15 are provided with A number of layered platforms 16, inside the layered platforms 16 are tensioned spring wires 17, after the test piece 18 passes through the spring wires 17, it is placed on the bottom of the segmented sealed pressure test chamber 1, and then the The stiffening screws 19 around the layered ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap