Workshop site information acquisition system

An information collection and on-site technology, applied in the field of information collection, can solve problems such as poor practicability, and achieve the effect of solving long-distance information transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

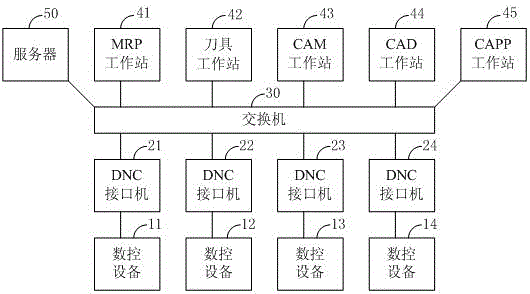

[0013] Compared with the communication between computers, the acquisition process of the running status of CNC equipment is much more complicated. During the operation of the digital production workshop, some automation devices can be used to monitor the working status of various switching I / O points online, so as to achieve the purpose of collecting the operating status information of the numerical control equipment. The information collection and transmission method of the numerical control equipment depends on the distributed numerical control (DNC, DistributedNumericalControl) interface provided by itself. In the 1990s, the CNC systems produced by major foreign CNC equipment companies mostly had DNC communication interfaces. As long as the corresponding interface software is configured, the information collection function can be realized, and an information exchange platform only needs to be established at the receiving end of the information. For the numerical control sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com