Fluid solid coupling dynamic characteristic prediction method for pipeline system

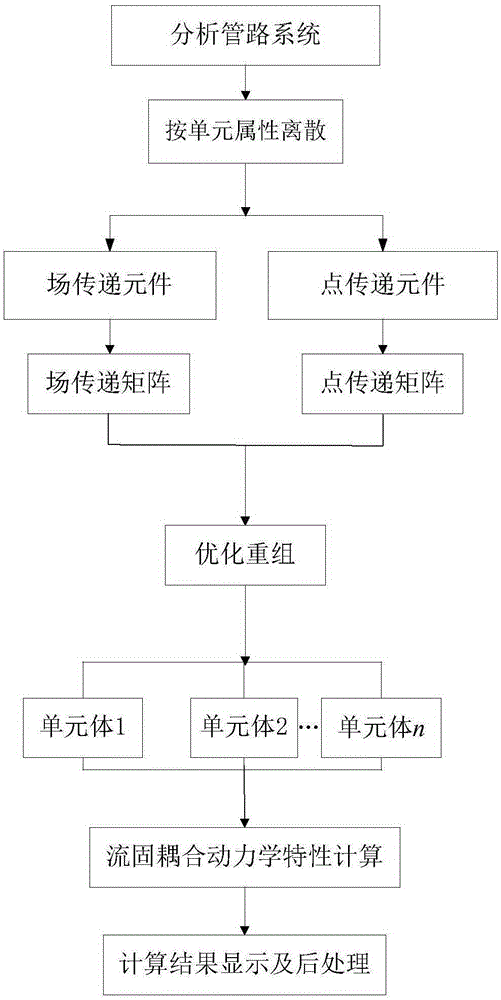

A technology of dynamic characteristics and pipeline system, which is applied in the field of prediction of fluid-solid coupling dynamic characteristics, can solve problems such as unstable prediction results, difficult modular programming prediction, calculation value overflow, etc., so as to facilitate programming calculation and ensure prediction Precision, the effect of eliminating numeric overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

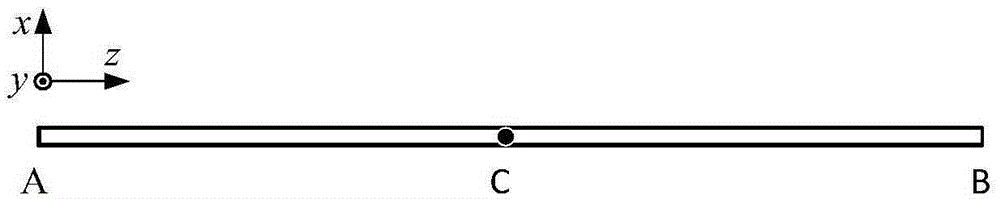

[0058] Such as figure 2 As shown, a long water-filled pipeline with free ends, the characteristic parameters of the pipeline system are shown in Table 1, and the unit excitation along the y direction is applied at the end of the pipeline.

[0059] Table 1 Pipeline structure and characteristic parameters of internal fluid

[0060]

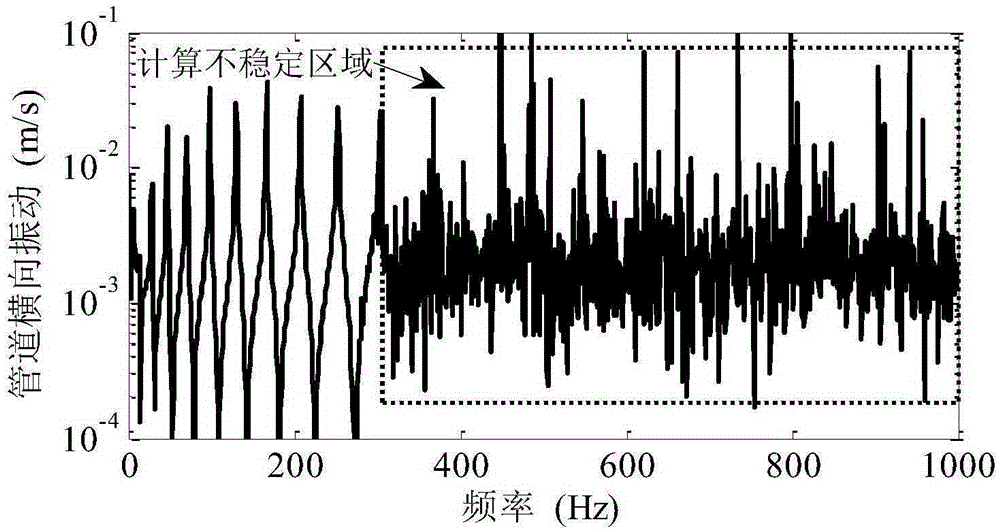

[0061] If the pipeline is calculated as a straight pipe as a whole (that is, a unit body), the calculated fluid-solid coupling response curve at end B is as follows image 3 As shown, after 255Hz, the results of the lateral vibration response of the pipeline become unstable.

[0062] image 3 The instability phenomenon is due to the fact that the characteristic length of the calculation unit body exceeds the maximum characteristic length specified by formula (1) or formula (2), according to image 3 , if the analysis frequency range is set to 0-1000Hz, then the upper limit frequency of the corresponding analysis is 1000Hz, according to the fo...

Embodiment 2

[0064] In this example Figure 5 The complex space pipeline system shown is the implementation object. The basic parameters of the pipeline structure material are: the elastic modulus is 200GPa, the Poisson’s ratio is 0.3, and the density is 7800kg / m 3 . Each boundary end is fixedly supported, each elastic support is suspended vertically (x direction), and the stiffness is 6.78×10 3 N / m. In the figure, 1 is the gate valve of DN100, 2 is the stop valve of DN100, 3 is the gate valve of DN65, and 4 is the stop valve of DN65. N 1 , N 2 , N 3 Springs with six degrees of freedom are connected at three places, and the stiffness in each direction is 1×10 9 N / m (approximate fixed support boundary condition), N 4 A linear spring with three degrees of freedom is connected at , and the spring stiffness in each direction is 8×10 6 N / m, the minimum wavelength of the pipe wall bending wave predicted by the piping system is 17m.

[0065] Apply excitation at the branch point, arbitrar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com