Power electronic capacitor for low-inductance light caseless vehicle

A technology of power electronics and low inductance, which is applied in the structural field of power electronic capacitors for vehicles, and can solve problems such as excessive temperature rise of capacitors, cracking and separation, and affecting the service life of capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

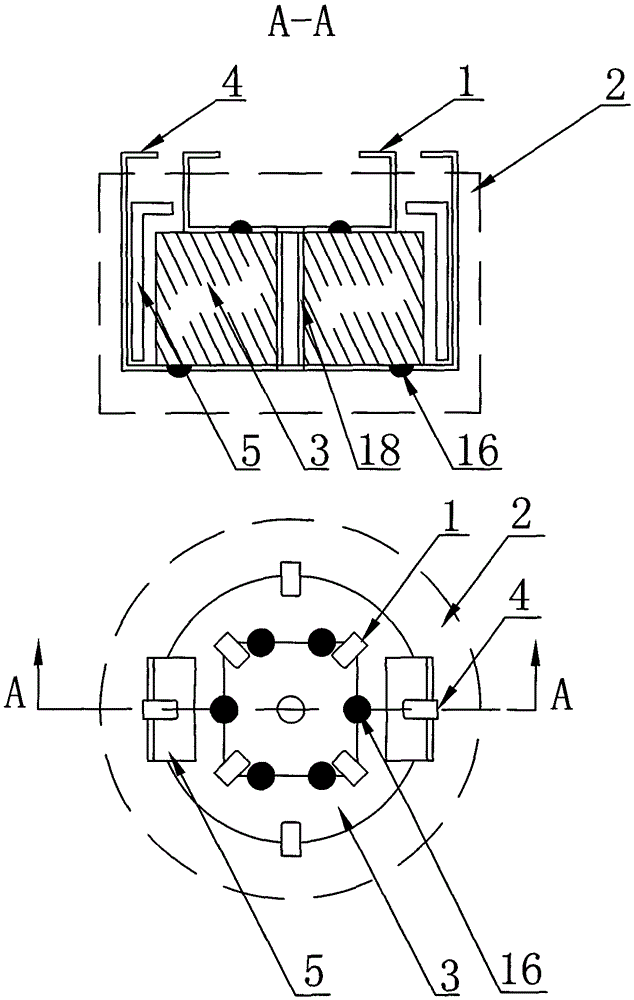

[0025] Embodiments of the present invention have low-inductance light-duty shellless vehicle power electronic capacitors such as figure 1 , figure 2 shown, including:

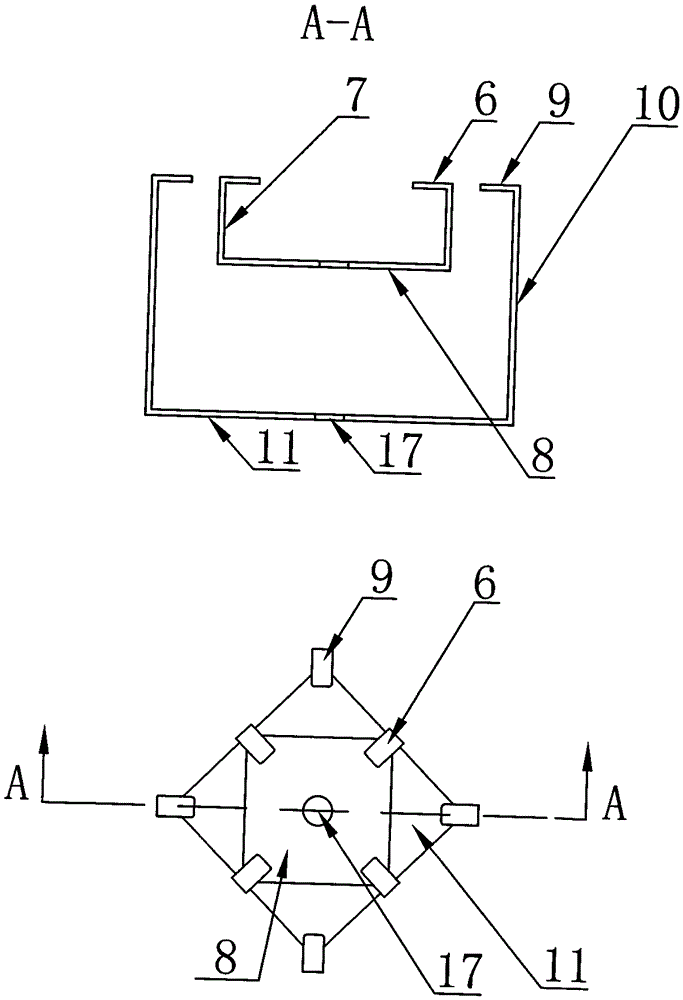

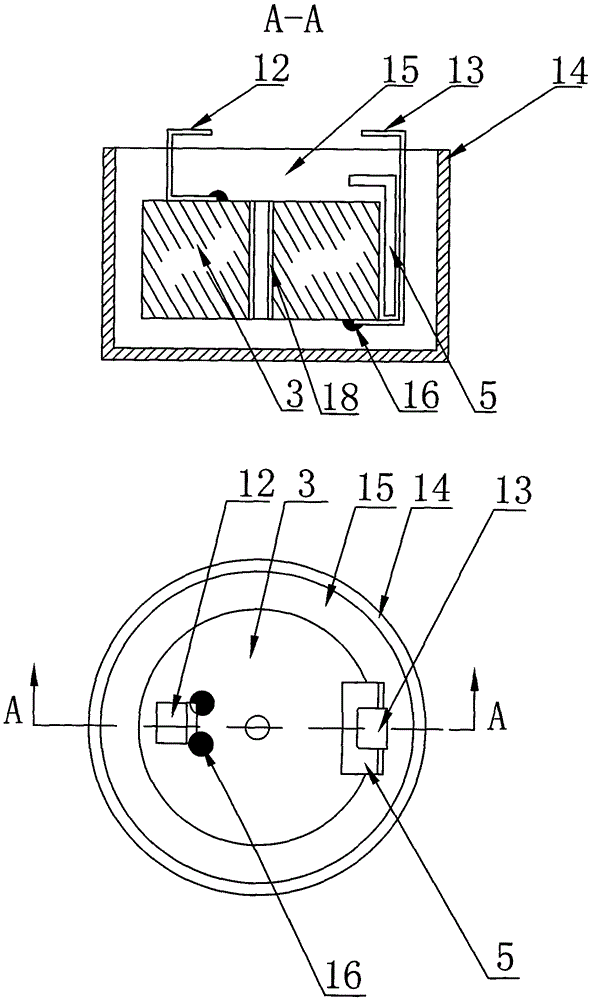

[0026] --Such as Figure 4 As shown in the first multi-terminal electrode assembly 1, such as Figure 5 and Figure 6 The second multi-terminal electrode assembly 4 is shown, a flexible polyester material encapsulation 2 and a capacitive winding core 3 fixed in the flexible polyester material encapsulation 2; the first multi-terminal electrode assembly 1 and the second multi-terminal electrode assembly 4 respectively have Fill the flow hole 17;

[0027] ——The first multi-terminal electrode assembly 1 and the second multi-terminal electrode assembly 4 respectively include the first connecting gold-spraying layer part 8 and the second connecting gold-spraying layer part 11, the first electrode lead-out 6 and the second electrode lead-out 9, the second electrode lead-out 1 intermediate conductive strip 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com