Hot knife actuated split nut type compression release device

A technology of split nut and release device, applied in the aerospace field, can solve the problems of non-repeatability, large impact, serious pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0031] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

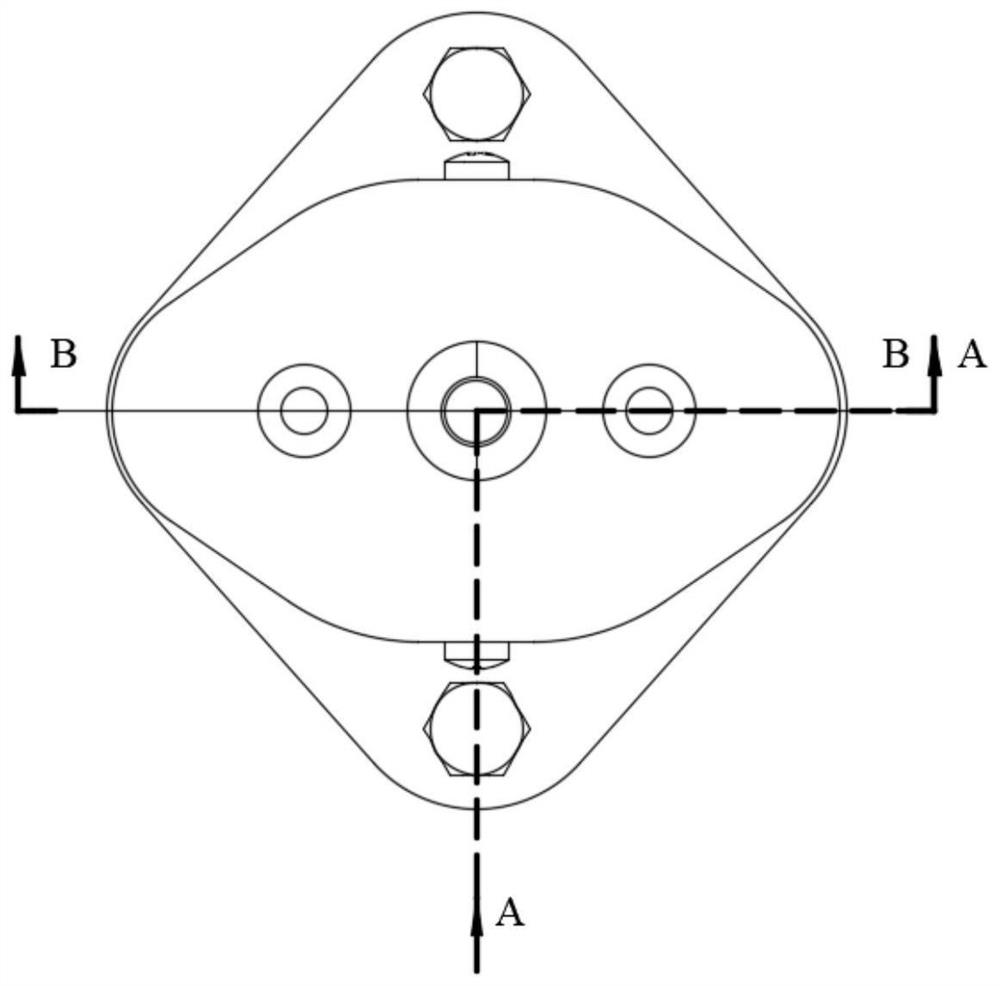

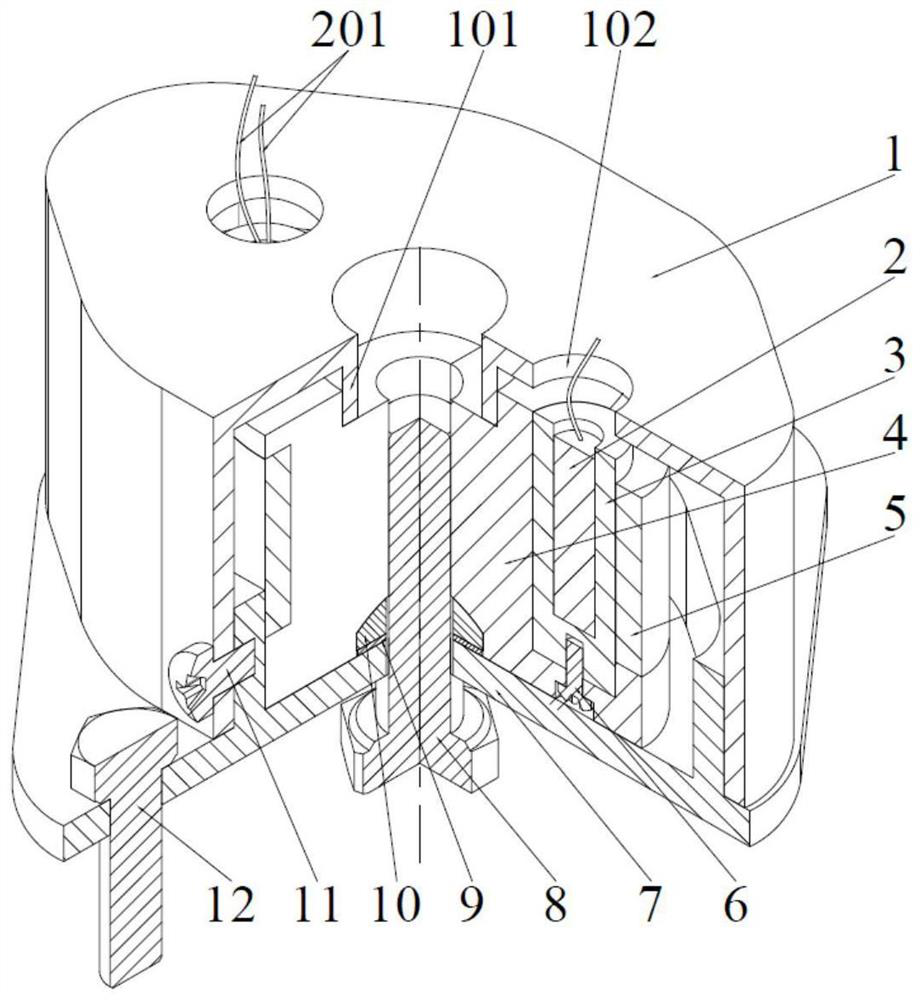

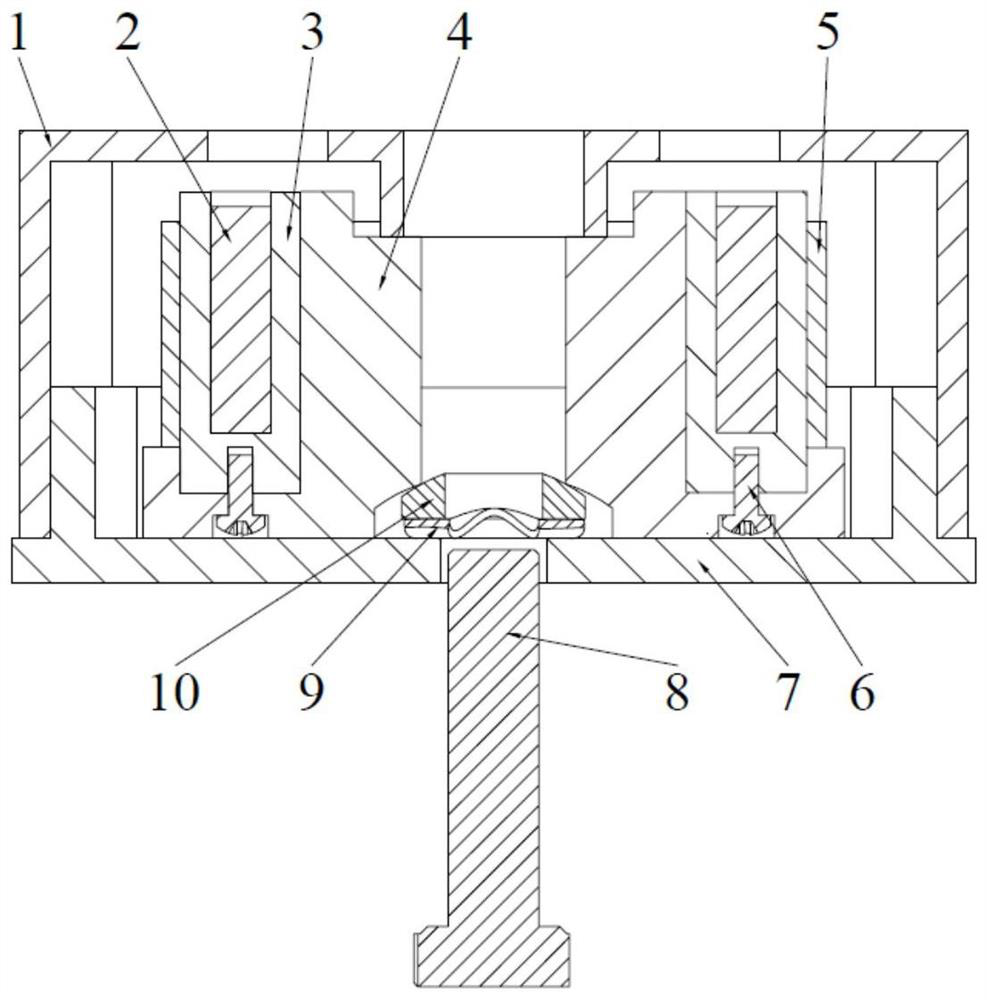

[0032] Such as Figure 1-Figure 5 As shown, a split nut type compression release device actuated by a hot knife includes two hot knives 2, two heat transfer sleeves 3, and two flaps arranged in a space enclosed by a top cover 1 and a base 7. The two-part split nut 4, the rope harness 5, the load-bearing bolt 8, the wave elastic washer 9 and the spherical washer 10 are arranged at the center of the space enclosed by the top cover 1 and the base 7, The two nut segments of the two-part split nut 4 are combined to form a complete thread, and two heat transfer sleeves 3 are symmetrically fixed on the two lobes of the two-part split nut 4, and one is set in each heat transfer sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com