Building circular arc component perforating machine

An arc-shaped, architectural technology, used in portable drilling rigs, drilling/drilling equipment, workbenches, etc., can solve problems such as inaccurate position deviation, and achieve the effects of accurate positioning, compact device, and easy portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

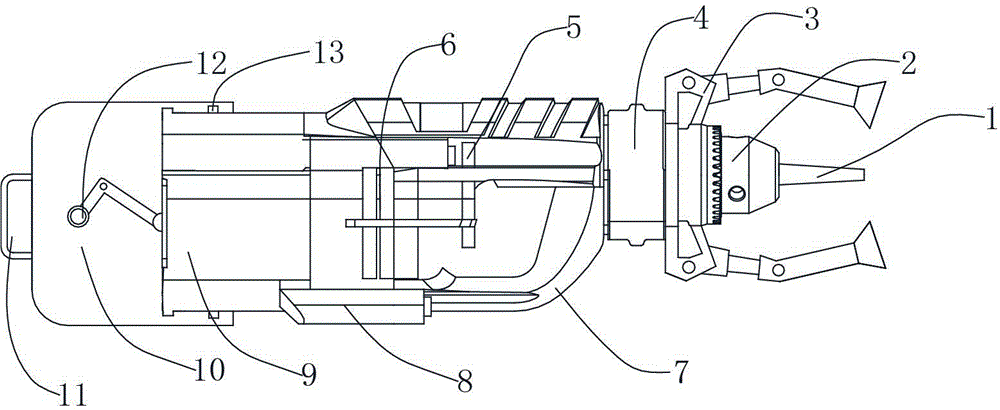

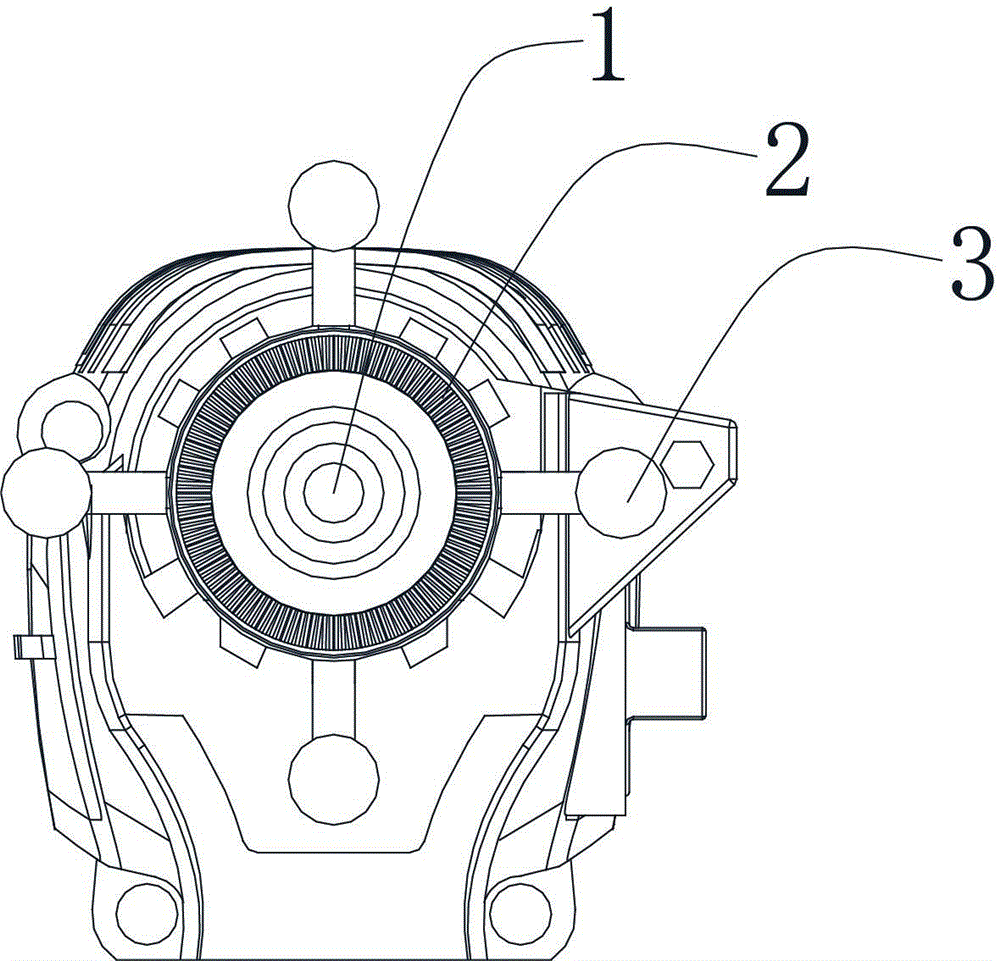

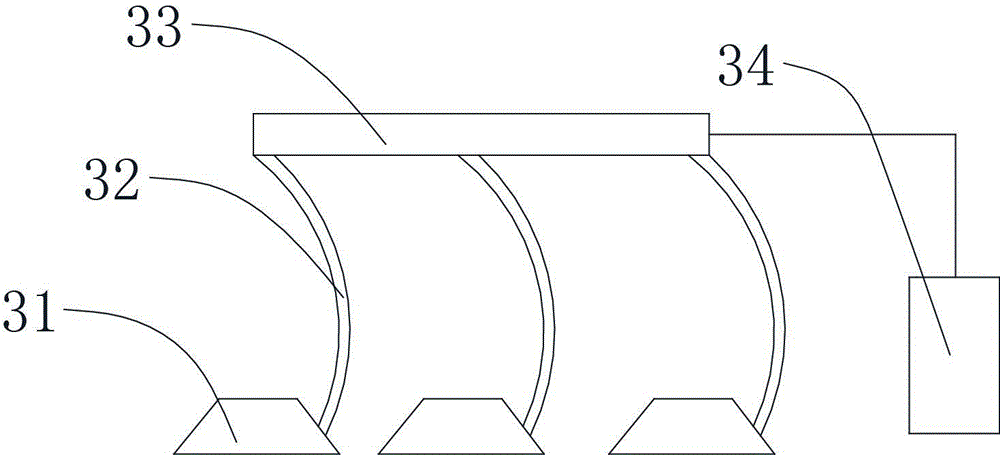

[0017] The arc-shaped part punching machine for construction includes a first housing 7, a drill chuck 2 is arranged at the front end of the first housing 7, a drill bit 1 is arranged inside the drill chuck 2, and the drill chuck 2 is provided with a drill bit 1. A mounting seat is provided on the chuck 2, and an annular positioning device 3 is provided on the mounting seat. The annular positioning device 3 includes a first contact arm and a second contact arm, and the first contact arm and the mounting seat Hinged, its lower end can be extended, the second contact arm is hinged with the first contact arm, the bottom is provided with a suction cup 31, the suction cup 31 is provided with a vacuum branch pipe 32, and the plurality of vacuum branch pipes 32 is connected to the vacuum main pipe 33, the end of the vacuum main pipe 33 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com