Method for predicating surface roughness of titanium alloy material based on milling

A surface roughness and milling technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of low accuracy and low generality of prediction models, and achieve the effect of improving prediction accuracy and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

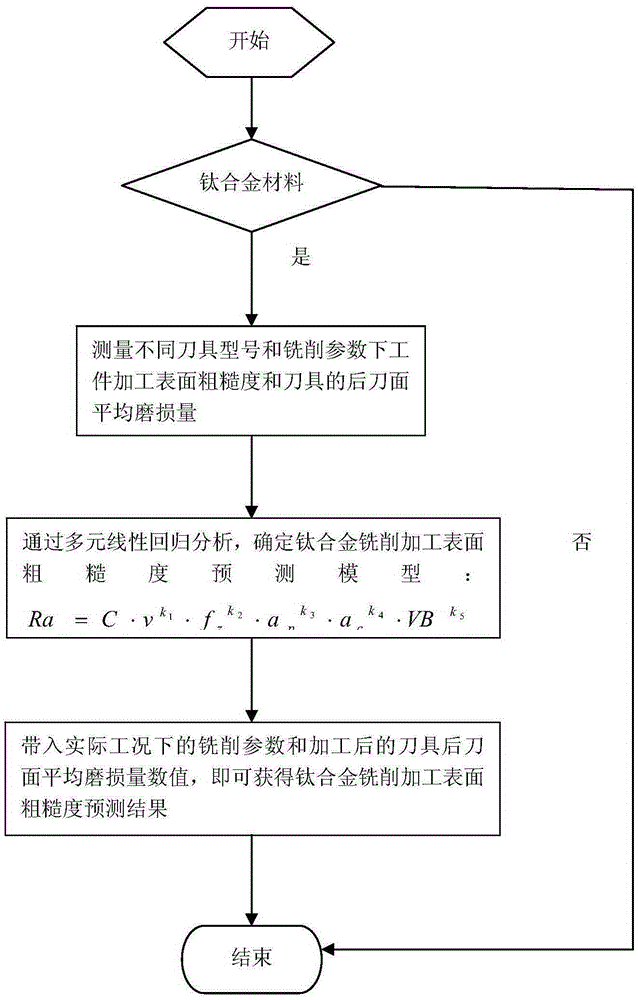

[0015] Please refer to figure 1 Shown, the present invention is based on the titanium alloy material surface roughness prediction method of milling processing, comprises the steps:

[0016] Step 1: Determine whether the material is a titanium alloy material. If it is a titanium alloy material, proceed to Step 2. If it is not a titanium alloy material, this prediction method is not applicable;

[0017] Step 2: Perform milling on several workpieces of the same material under different tool types and milling parameters, and then measure the surface roughness value Ra of each workpiece and the average flank wear VB of each tool;

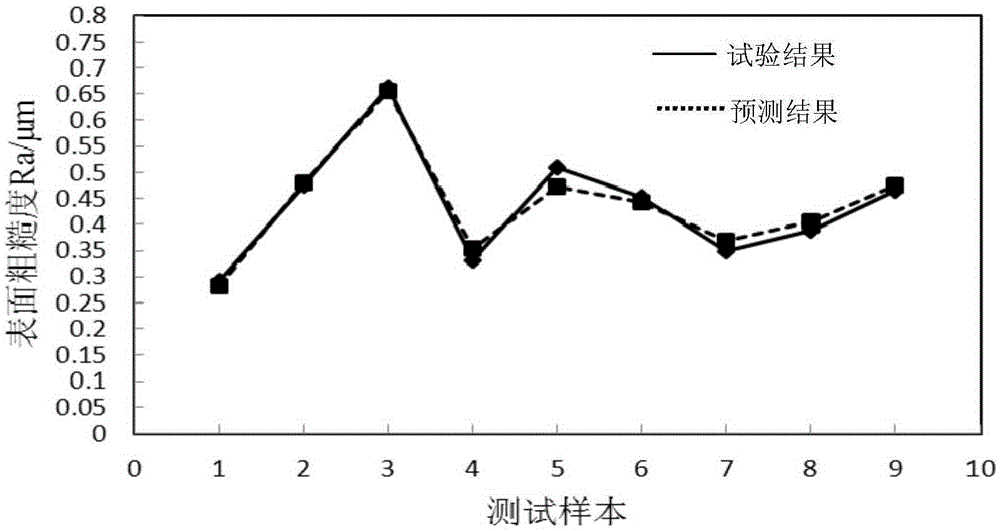

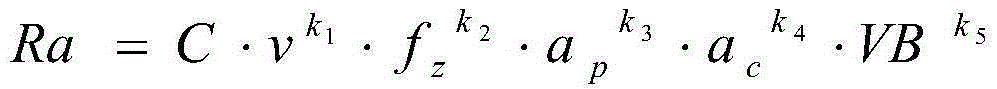

[0018] Step 3: Perform multiple linear regression analysis on the measurement results of workpieces milled with the same type of tool to determine the surface roughness prediction model: R a = C · v k 1 · f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com