Full-automatic grinding machine applied to metal surface machining assembly line

An assembly line and fully automatic technology, applied in metal processing equipment, grinding racks, grinding machines, etc., can solve problems such as production errors, waste of manpower, and errors in manual operations, and achieve accurate counting, improve efficiency, and save manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

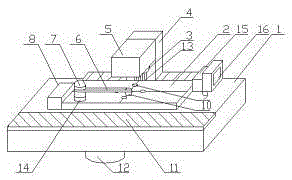

[0009] A full-automatic grinding machine applied to a metal surface processing line, comprising: an assembly line table 1, a grinding table 2, a grinding wheel 3, a guide rail mounting seat 4, a grinding wheel mounting seat 5, a rotating arm 6, a rotating shaft 7, and a rotating arm controller 8. Suction hole 9, small vacuum sucker 10, conveyor belt 11, vacuum generator 12, guide rail 13, rotating motor 14, controller 15, counter 16, a conveyor belt 11 is installed above the assembly line table 1, and a grinding table 2 is installed on one side of the conveyor belt 11. A suction hole 9 is provided on the grinding table 2, a vacuum generator 12 is installed below the suction hole 9, a rotating motor 14 is installed on one side of the grinding table 2, a rotating shaft 7 is installed above the rotating motor 14, a rotating arm 6 is installed above the rotating shaft 7, and one end of the rotating arm 6 is installed Small vacuum suction cup 10, arm controller 8 is installed on one...

Embodiment 2

[0011] The conveyor belt 11 sends the workpiece to the assembly line table top 1 and then stops. The rotating arm controller 8 controls the rotating motor 14 to run, so that the rotating arm 6 rotates. After the small vacuum chuck 10 reaches the top of the workpiece, it stops. The small vacuum chuck 10 runs to suck the workpiece. Stop, the rotating arm 6 rotates again to place the workpiece on the grinding table 2, the small vacuum suction cup 10 stops running, the rotating arm 6 resets, the controller 15 controls the operation of the vacuum generator 12, and the workpiece is fixed on the grinding table 2 through the suction hole 9 At the same time, the grinding wheel mounting seat 5 moves downward on the guide rail 13 to grind the workpiece. After grinding, the grinding wheel mounting seat 5 moves upward, the vacuum generator 12 stops running, the counter 16 counts once, and the rotating arm 6 rotates again to remove the workpiece from Take it out on the grinding table 2 and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com